Wound oxygen supply dressing based on liquid material and production method thereof

A wound dressing and liquid material technology, applied in the field of medical hygiene products, can solve problems such as poor healing effect, and achieve the effects of beautiful wounds, repairing scars, and large dressing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

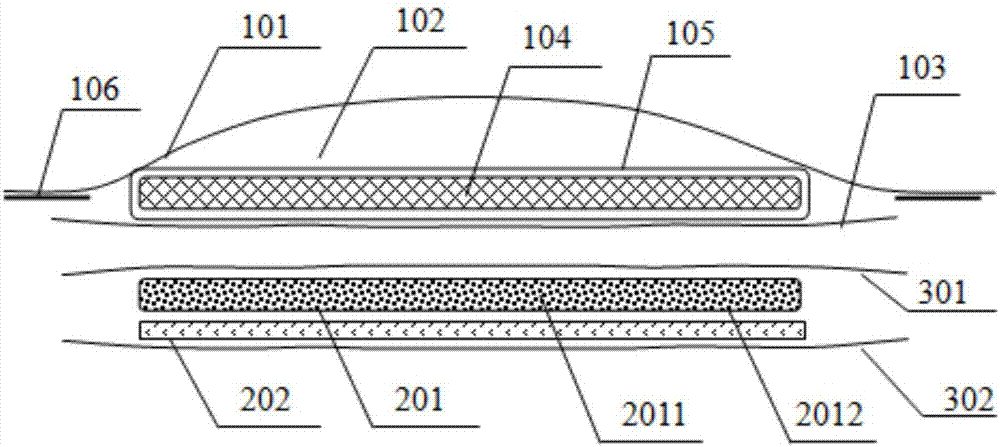

[0033] like figure 1 As shown, a wound dressing based on liquid material for oxygen supply is characterized in that: the dressing is composed of a dressing unit, and the dressing unit is divided into two parts: the first part is mainly composed of a waterproof membrane 101 from top to bottom, a hydrogen peroxide storage container 102, and a protective The waterproof membrane 101 is composed of a membrane 103, and the waterproof membrane 101 is located on the outermost layer to achieve a sealing effect when the dressing sticks to the skin. The waterproof membrane 101 can be made of polyethylene, which can prevent dust, water, air leakage and pollution. The container wall of the hydrogen peroxide storage container 102 towards the wound side is provided with a small hole 4, hydrogen peroxide is stored in the hydrogen peroxide storage container 102, and the hydrogen peroxide concentration is 3% hydrogen peroxide, i.e. medical hydrogen peroxide. During the use of the dressing, the ...

Embodiment 2

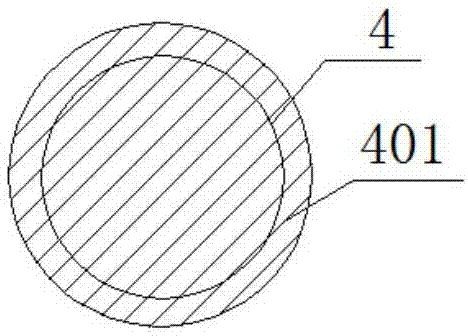

[0048] like figure 1 and 2 As shown, the difference between this embodiment and Embodiment 1 is that the container wall of the hydrogen peroxide storage container 102 facing the wound is provided with a small hole 4 with a larger aperture, and a layer of permeable water is adhered to the outer surface of the small hole 4. Membrane 401 allows hydrogen peroxide to seep out at a certain rate, and generates oxygen after contacting the catalyst. The advantage of this design is that hydrogen peroxide can continuously permeate and generate oxygen, which can maintain the amount of oxygen on the wound surface and avoid failure due to leakage. The permeable membrane 401 can be made of polyamide, polyimide, polyethersulfone, etc. During storage and transportation, since the protective film 103 is pasted on the surface, the liquid will not leak.

[0049] The preparation method of hydrogen peroxide reservoir 102 in this embodiment comprises the steps:

[0050] 1) The container wall of t...

Embodiment 3

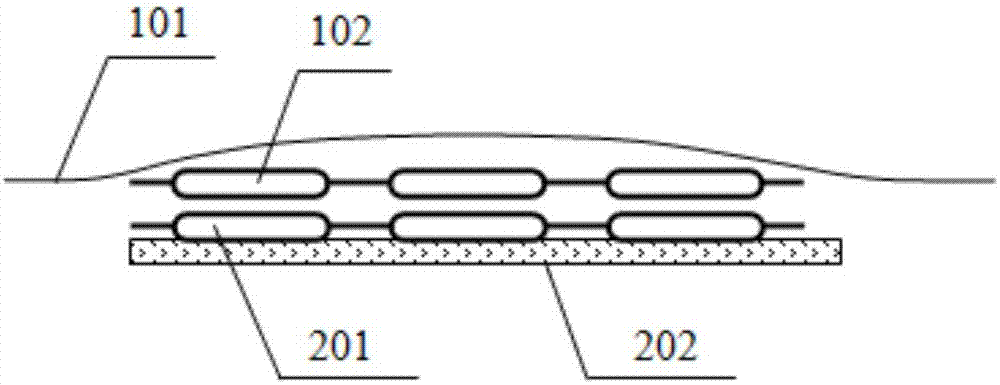

[0055] like Figure 3-5 As shown, the difference between this embodiment and Embodiment 1 is that the dressing includes at least one dressing unit, such as Figure 3-5 As shown, a plurality of dressing units can be arranged and combined. When used for small wounds, the dressing area is small, and a single dressing unit can be used; when used for large wounds, the dressing area is large, and if cutting is required, it can be designed as a combination of multiple dressing units. The advantage of this design is that it can be used It can be cut according to the size of the wound; it is beneficial for the reagent to be evenly distributed on the surface of the dressing, so as to prevent the phenomenon that the liquid flows to one side due to the position and angle during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com