A kind of aquaculture cage cleaning device

A cleaning device and aquaculture technology, applied in fish farming, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of high physical exertion of operators, inability to use for aquaculture, damage to water quality in the box, etc., and reduce physical strength. Consume, improve cleaning effect, clean up reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

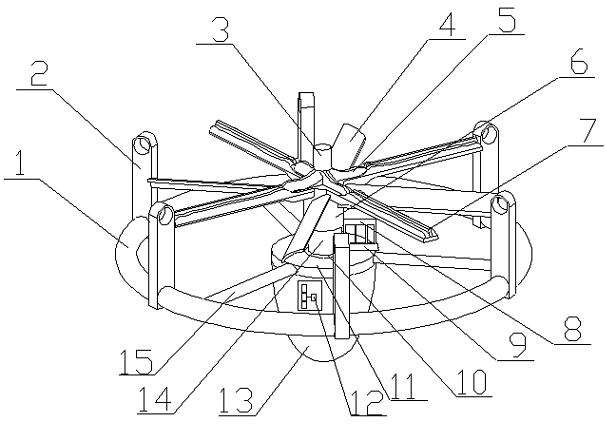

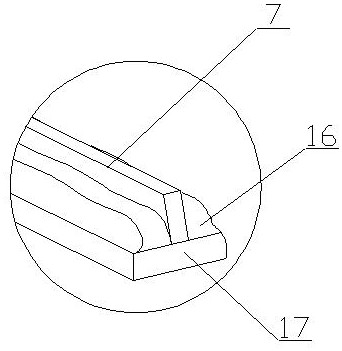

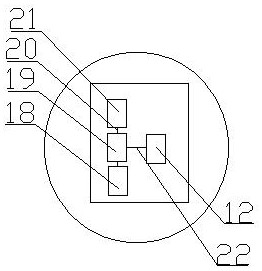

[0032]An aquaculture net cage cleaning device of the present invention is realized in this way. When in use, when cleaning the aquaculture net cage, the fixing ring (1) is first installed and fixed on the At the bottom of the aquaculture cage, the multiple support plates (17) are closely attached to the bottom of the cage, and the turbidimeter (3) enters the inside of the aquaculture cage through the mesh hole at the bottom of the aquaculture cage, and the motor shaft (14) rotate, drive the connecting sleeve (6) and the connecting plate (8) to rotate, the connecting sleeve (6) drives the connected set of blades (4) and multiple support plates (17) to rotate, and drives the turbidimeter (3 ) rotates, a plurality of support plates (17) rotate around the motor shaft (14), during the rotation process, the bristles of the brushes (7) on the support plates (17) are bent and stretched under the obstruction of the net wire of the aquaculture cage straight, to clean the net wires and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com