Bearing and thermal protection integrated wing leading edge structure based on micro-truss

A wing leading edge, micro-truss technology, applied in wings, aircraft parts, transportation and packaging, etc., can solve problems such as insufficient load-bearing performance, weakened bonding performance between panels and core materials, and achieve weight reduction and isolation. External high temperature, the effect of reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

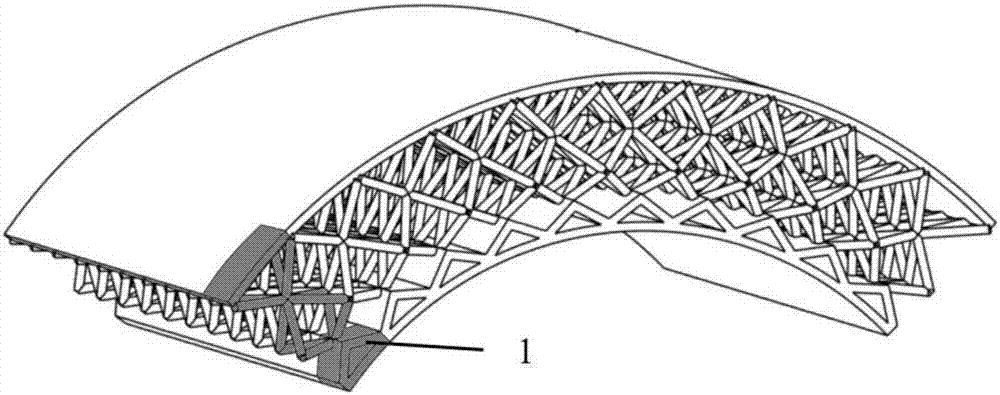

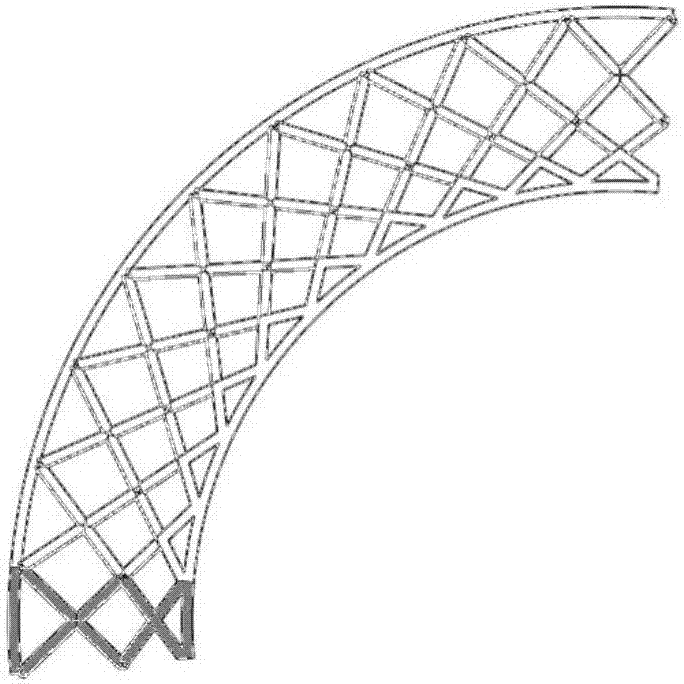

[0030] The present invention provides a load-bearing / thermal protection integrated wing leading edge structure based on micro-truss, such as Figure 1 ~ Figure 2 As shown, the integrated wing leading edge structure includes several periodic structural units 1, and the periodic structural units 1 are arranged in a matrix of 10×10.

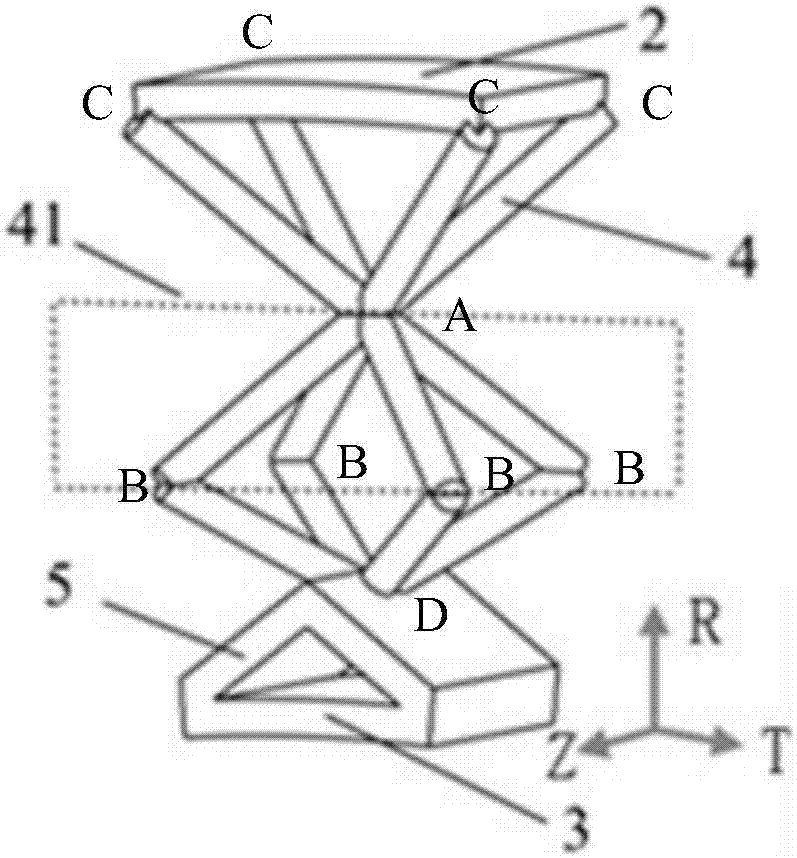

[0031] According to the structural symmetry, a unit cell of a periodic structural unit is selected for illustration, such as Figure 3-5 As shown, where the unit cell coordinate system is as image 3 As shown in , R, T, and Z correspond to the radial direction, circumferential direction, and axial direction of the cylinder respectively, and the periodic structural unit 1 is sequentially composed of an upper panel 2, a core 4, a flow channel, and a lower panel 3 in the radial direction, The core 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com