Method for separating chemical-grade isoprene

A technology of isoprene and separation method, which is applied in the field of separation of chemical grade isoprene, can solve the problem of inability to balance energy consumption and isoprene yield, purity, and inability to obtain pure isoprene, purification and Regenerate high-level problems, achieve the effect of shortening the residence time, reducing equipment investment, and increasing the total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Embodiment [1-10]

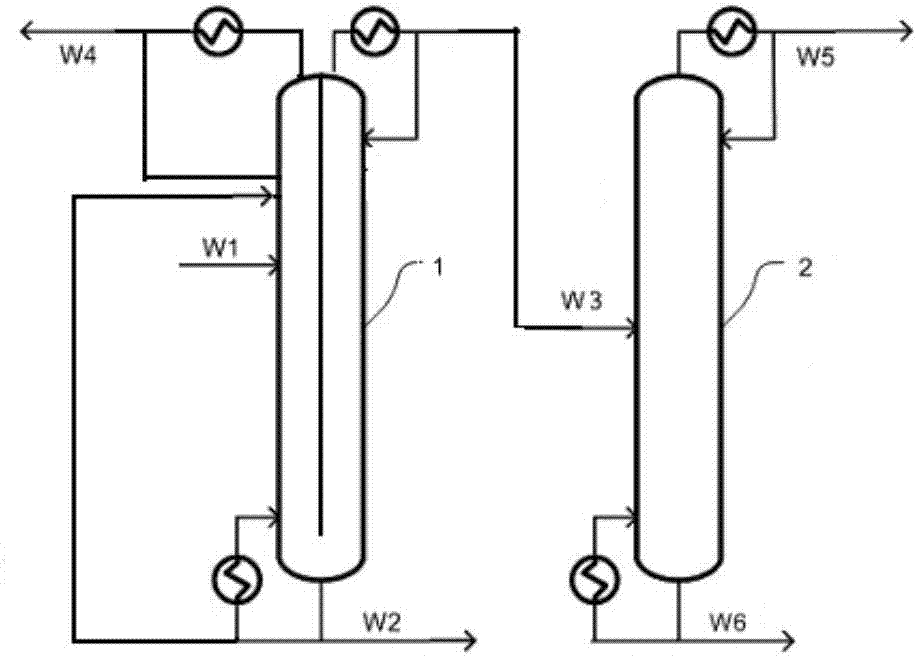

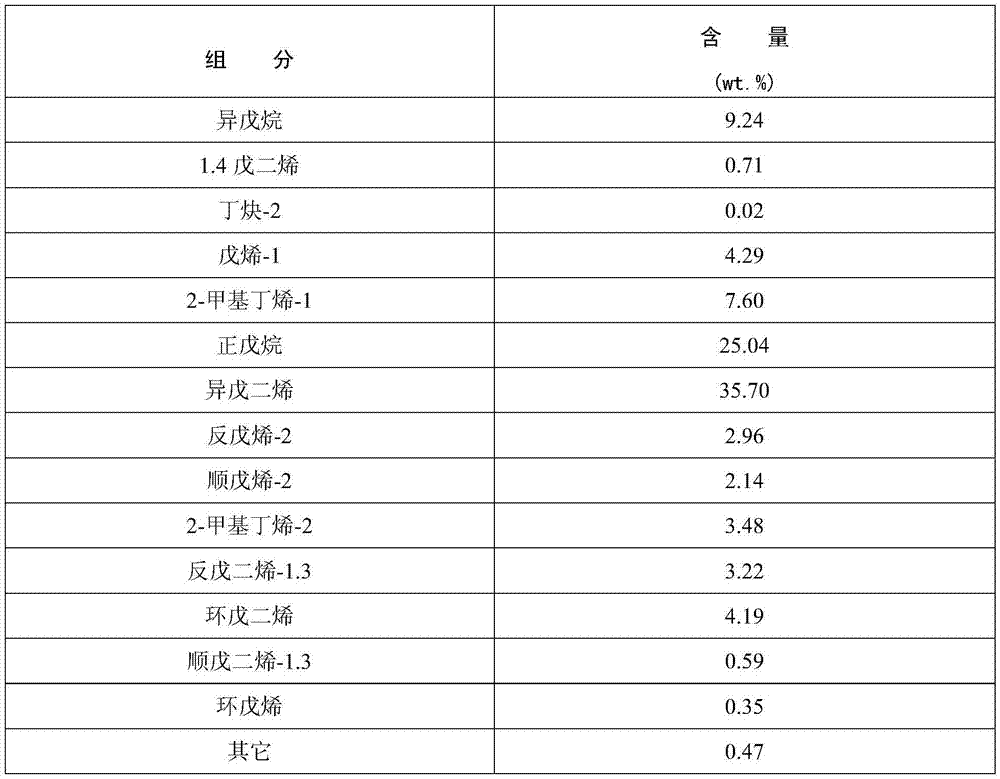

[0022] The technological process of embodiment 1~10 sees figure 1 , the raw material W1 is a C5 raw material from which cyclopentadiene has been pretreated, and its main composition is shown in Table 1.

[0023] The process and operating conditions of separation tower 1 and weight removal tower 2 are shown in Table 2 and Table 3 respectively. The composition of isoprene in the product was analyzed by gas chromatography, and the yield of isoprene was calculated in combination with the flow rate of each material. The results are shown in Table 4.

[0024] Table 1.

[0025]

[0026] Table 2.

[0027]

[0028] table 3

[0029]

[0030] Table 4.

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com