Keyboard protective film

A technology for protective film and keyboard, applied in the field of keyboard protective film, can solve the problem of poor antibacterial performance of keyboard film, and achieve the effects of avoiding microbial adhesion, densifying surface structure, and improving antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

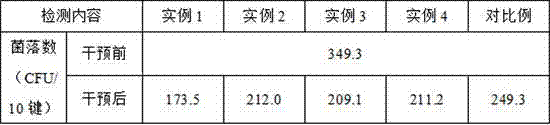

Examples

example 1

[0038]Mix the tea leaves and pomegranate peels in a beaker at a mass ratio of 3:2, and add mugwort 0.6 times the mass of tea leaves and water 5 times the mass of tea leaves into the beaker, and move the beaker into a magnetic stirrer with digital speed measurement and constant temperature. Under the conditions of 100°C, rotating speed of 350r / min, heat, stir and boil for 4 hours, then filter to obtain the mixed liquid, transfer the mixed liquid to a rotary evaporator, and press at a temperature of 65°C, rotating speed of 180r / min, and pressing pressure of 800kPa Rotate and concentrate for 80 minutes to obtain a mixed extract; mix ginger oil and sage oil in a flask at a mass ratio of 1:5, and add black pepper oil 0.4 times the mass of sage oil to the flask, and move the flask into Digital display speed measurement and constant temperature magnetic stirrer, under the condition of temperature 85 ℃ and speed 350r / min, stir and mix for 50min to obtain mixed essential oil; mix glass ...

example 2

[0040] Mix the tea leaves and pomegranate peels in a beaker at a mass ratio of 3:2, and add mugwort 0.6 times the mass of tea leaves and water 5 times the mass of tea leaves into the beaker, and move the beaker into a magnetic stirrer with digital speed measurement and constant temperature. Under the conditions of 100°C, rotating speed of 350r / min, heat, stir and boil for 4 hours, then filter to obtain the mixed liquid, transfer the mixed liquid to a rotary evaporator, and press at a temperature of 65°C, rotating speed of 180r / min, and pressing pressure of 800kPa Rotate and concentrate for 80 minutes to obtain a mixed extract; mix ginger oil and sage oil in a flask at a mass ratio of 1:5, and add black pepper oil 0.4 times the mass of sage oil to the flask, and move the flask into Digital display speed measurement and constant temperature magnetic stirrer, under the condition of temperature 85 ℃ and rotation speed 350r / min, stir and mix for 50min to obtain mixed essential oil; ...

example 3

[0042] Mix the tea leaves and pomegranate peels in a beaker at a mass ratio of 3:2, and add mugwort 0.6 times the mass of tea leaves and water 5 times the mass of tea leaves into the beaker, and move the beaker into a magnetic stirrer with digital speed measurement and constant temperature. Under the conditions of 100°C, rotating speed of 350r / min, heat, stir and boil for 4 hours, then filter to obtain the mixed liquid, transfer the mixed liquid to a rotary evaporator, and press at a temperature of 65°C, rotating speed of 180r / min, and pressing pressure of 800kPa Rotate and concentrate for 80 minutes to obtain a mixed extract; mix ginger oil and sage oil in a flask at a mass ratio of 1:5, and add black pepper oil 0.4 times the mass of sage oil to the flask, and move the flask into Digital display speed measurement and constant temperature magnetic stirrer, under the condition of temperature 85 ℃ and speed 350r / min, stir and mix for 50min to obtain mixed essential oil; mix glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com