Pelletizing device for titanium concentrate

A technology of ilmenite concentrate and cylinder body is applied in the field of granulation device of ilmenite concentrate, which can solve the problems of difficulty in granulating and pelletizing the ilmenite concentrate, increase the sintering time, and high operating cost, achieve simple structure, reduce moisture, Good granulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

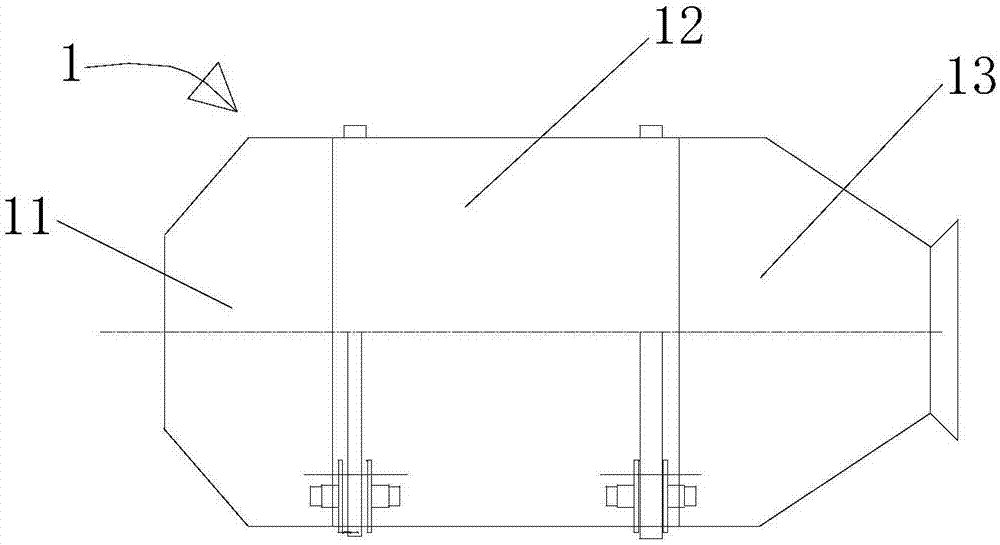

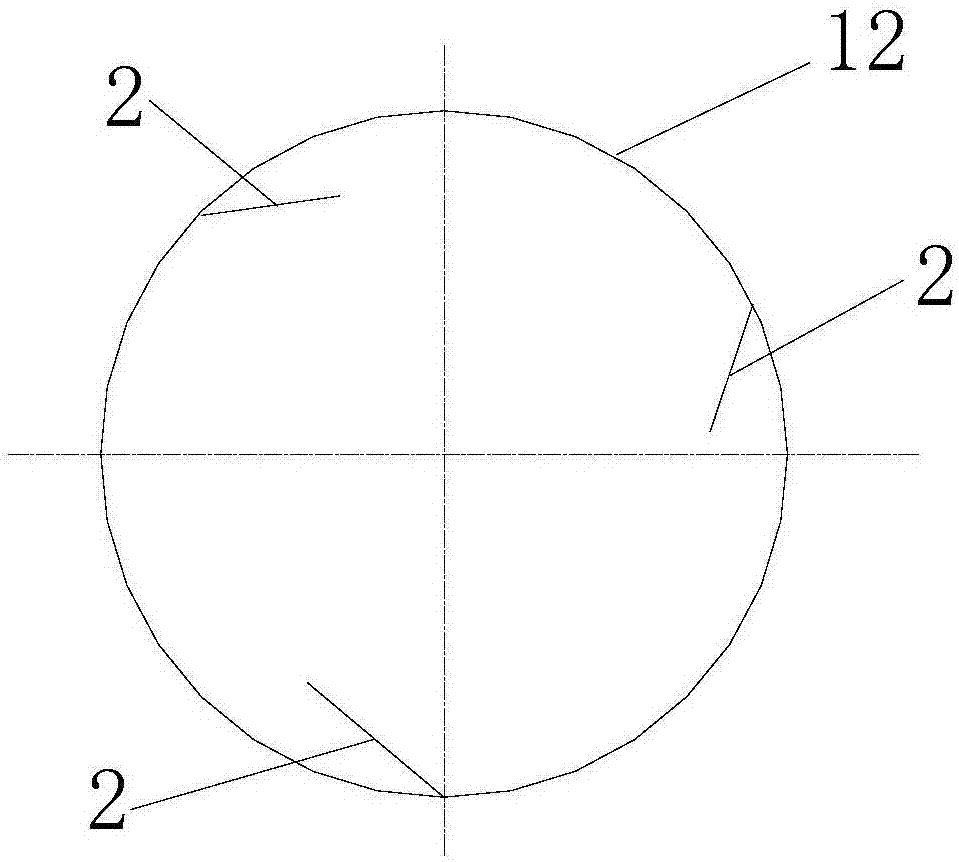

[0017] Such as figure 1 , figure 2 As shown, a granulation device for titanium concentrate includes a rotating main cylinder body 1, and the main cylinder body 1 is divided into a front section cylinder body 11, a middle section cylinder body 12, a rear section cylinder body 13, and a middle section cylinder body 12. The shape is cylindrical, and along the length direction of the middle barrel 12, multiple rows of granulation structures parallel to each other are arranged on the inner wall surface of the middle barrel 12. Each row of granulation structures is composed of a plurality of cylindrical lifting plates 2, each The cylindrical lifting plates 2 in the row granulation structure are evenly distributed in the circumferential direction of the cylinder body 12 in the middle section.

[0018] When the titanium concentrate raw material enters the main cylinder 1, the ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com