A nano-carbon alloy material and electric fittings prepared based on the material

A technology of alloy materials and electric power fittings, which is applied in the field of nanomaterials, can solve the problems of bulky and bulky appearance of fittings, inconvenient installation and transportation, etc., and achieve the effects of reducing transportation and installation costs, promoting technology upgrades, and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

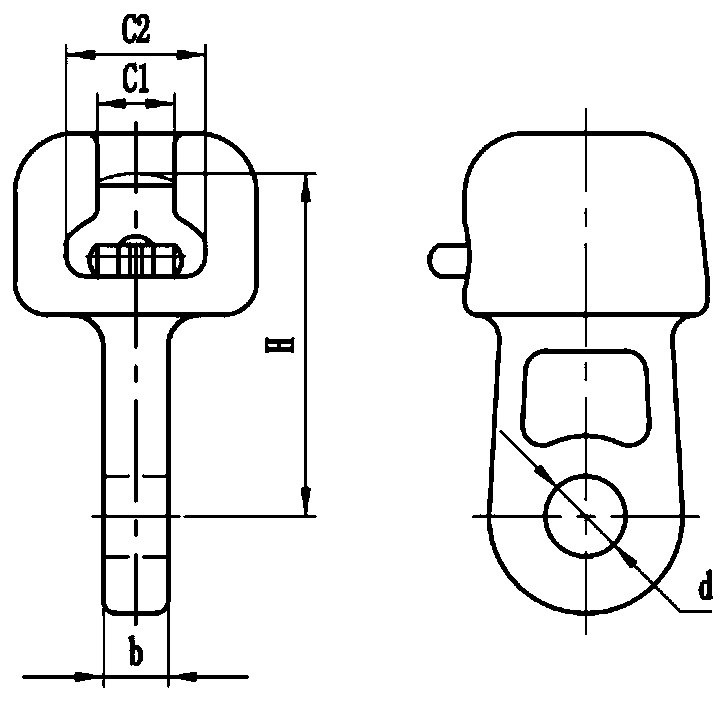

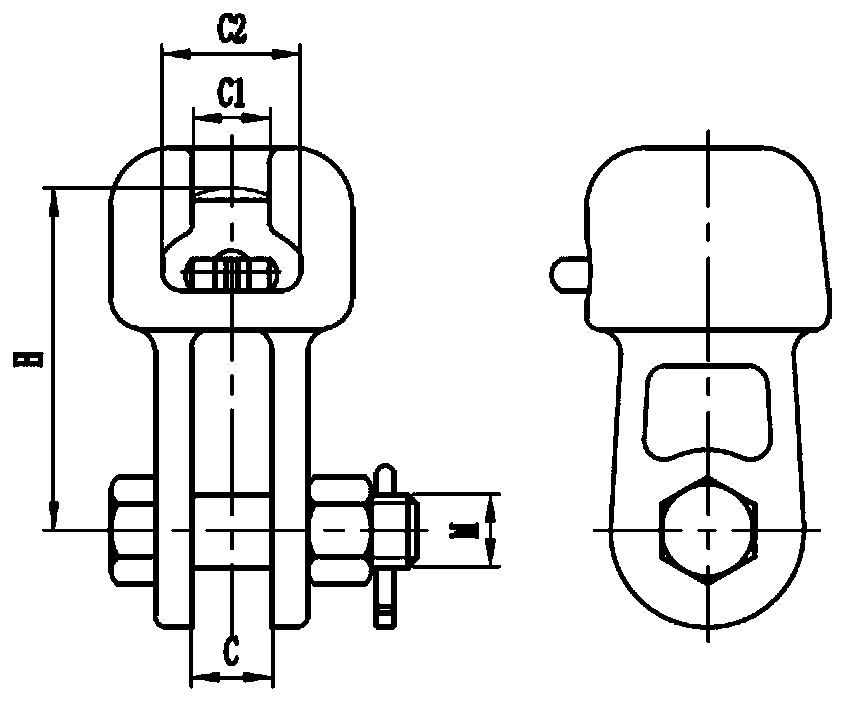

[0022] To prepare a bowl head hanging board power fitting made of nano-carbon alloy material, the specific steps are as follows:

[0023] 1) Al-Si master alloy (Si accounts for 10.4%), Al-Cu master alloy (Cu accounts for 50%), Al-Fe master alloy (Fe accounts for 20%), Al-Cr master alloy (Cr accounts for Ratio 3%), pure Mg blocks, carbon nanotubes, aluminum ingots as raw materials, the raw materials are weighed according to the following element mass ratios: Si 0.5%, Mg 0.8%, carbon nanotubes 0.5%, Cu 0.15%, Fe 0.25%, Cr 0.15%, the balance is Al, control the trace elements Mn<0.1%, Zn<0.1%, Ti<0.1%, put the aluminum ingot in the medium frequency induction furnace, heat it to melt, add the master alloy and stir evenly, and then use a bell The hood presses the pure Mg block into the bottom of the molten aluminum to fully melt, then add carbon nanotubes, then mechanically stir for 30 minutes, and then cast with a crystallizer (the crystallizer table temperature is set at about 700...

Embodiment 2

[0028] To prepare a bowl head hanging plate electric fitting made of nano-carbon alloy material, the preparation method is similar to that of Example 1, except that the addition amount of carbon nanotubes is 1.0%.

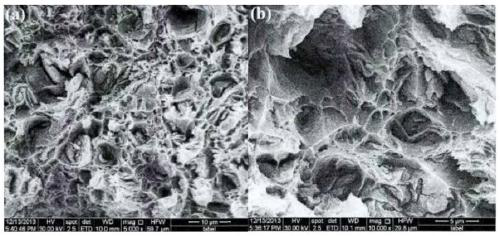

[0029] Such as figure 2 Shown is the SEM photo of the fracture of the bowl head hanging plate prepared in this example. It can be seen from the figure that the fracture is almost covered with a large number of tiny dimples, and there are holes between the dimples, showing the characteristics of micropore aggregation type shear fracture , belonging to ductile fracture. Some carbon nanotubes are distributed on the edge of the dimples and in the middle of the dimples, and the carbon tubes have not been completely pulled out, indicating that the carbon nanotubes and the matrix are well bonded.

[0030] A performance test was carried out on the NWS type bowl-head hanging board prepared in this embodiment, and the test results are shown in Table 1.

Embodiment 3

[0032] A kind of electric fittings with bowl head hanging plate made of nano-carbon alloy material is prepared, the preparation method is similar to that of Example 1, except that the addition amount of carbon nanotubes is 1.5%.

[0033] A performance test was carried out on the NWS type bowl-head hanging board prepared in this embodiment, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com