Preparation of membrane electrode for electrolytic tank and application of membrane electrode

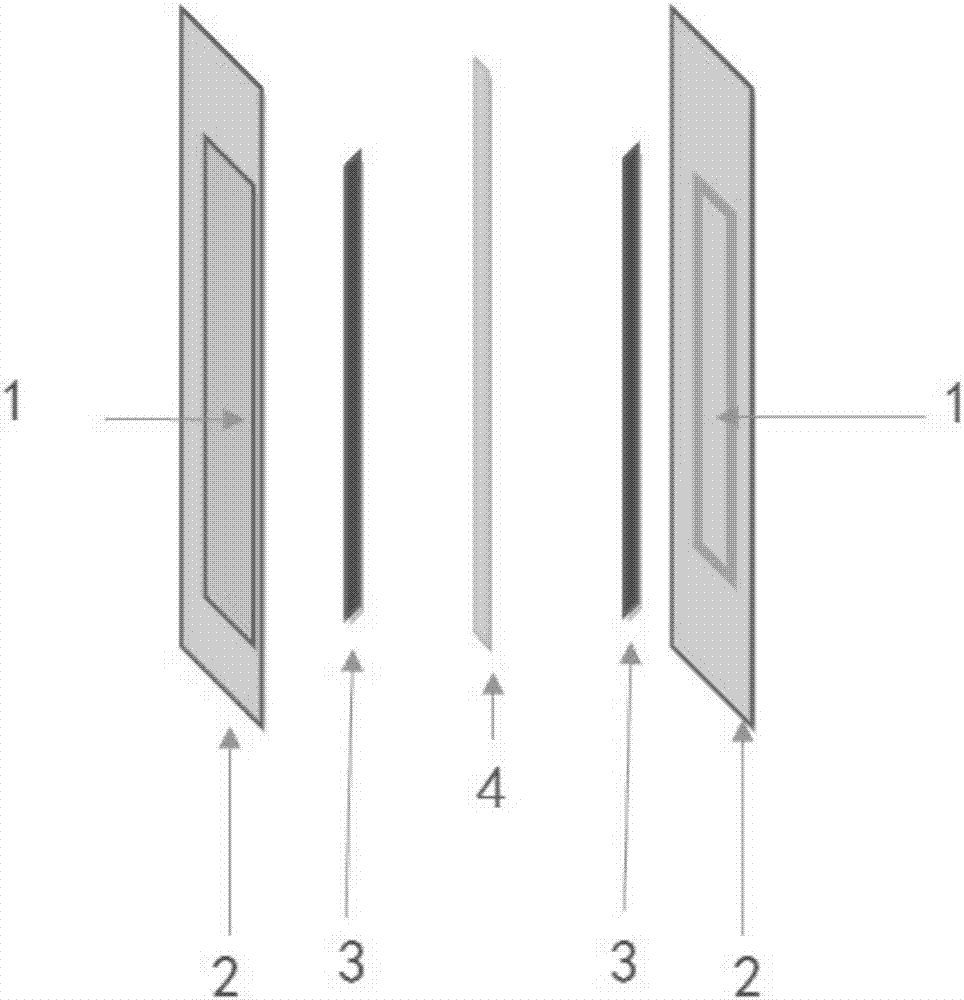

A membrane electrode and electrolytic cell technology, applied in the direction of electrodes, electrolytic process, electrolytic components, etc., can solve the problem of incomplete contact between gas diffusion layer electrodes and proton exchange membrane surfaces, and achieve high product preparation efficiency, simple and easy to control methods, Effect of reducing ohmic drop loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of catalyst slurry: first take by weighing 93mg Ir black, 62mg 70wt.% Pt / C, then mix in a certain amount of ethanol according to the mass ratio of catalyst and Nafion according to 4:1, the ratio of catalyst and ethanol The mass ratio is 1:40, and the mixed slurry is ultrasonically mixed for 20 minutes;

[0036] (2) Spraying of catalyst slurry: Spray the ultrasonically uniform catalyst slurry in (1) on both sides of the membrane. The above spraying operations are all carried out on a hot stage, and the temperature of the hot stage is kept constant at 60°C.

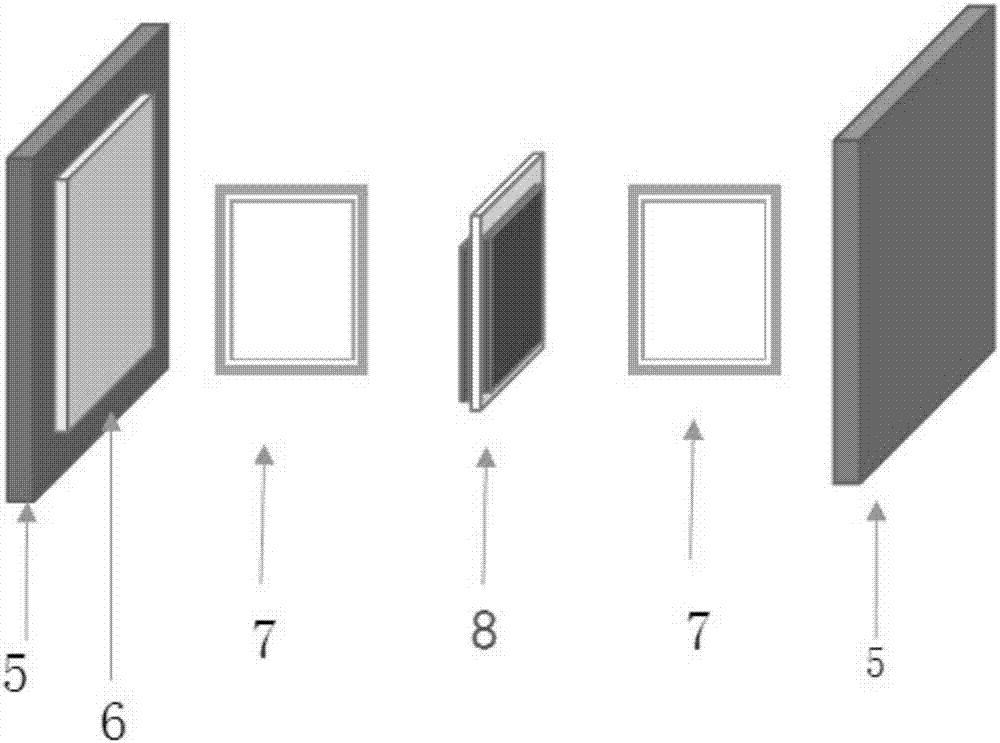

[0037](3) Cut the sealing material: the sealing material is divided into two pieces, the inner frame of the sealing material on the cathode side is 3.0 cm long and 2.5 cm wide, the inner frame of the sealing material on the anode side is 2.5 cm long and 2.0 cm wide, and the inner frame of the sealing material is 2.0 cm wide. The difference in size is to avoid tearing the film due to excessive shear st...

Embodiment 2

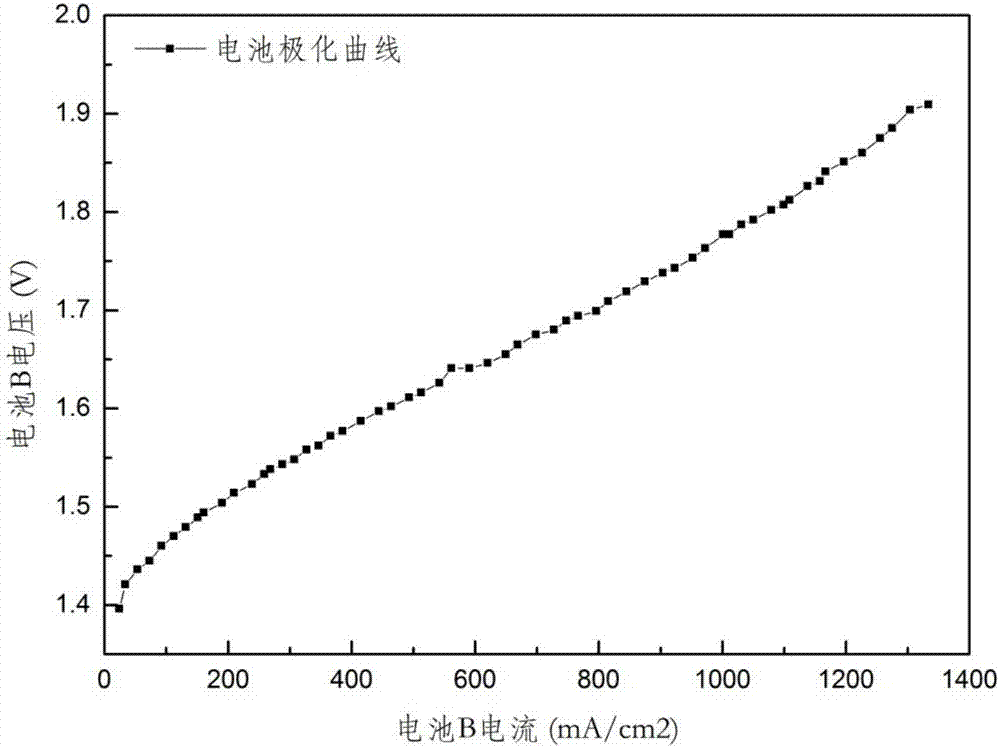

[0041] During the experiment, it was found that the content of Nafion in the catalytic layer will affect the overall performance of the electrolytic cell. By adjusting the distribution ratio of different components in the MEA preparation process, when the mass ratio of catalyst to Nafion (AS-4) in the catalytic layer is 5 When :1, the performance of the electrolytic cell is improved. Figure 4 It is the full battery steady-state polarization curve under the same test conditions as Example 1. At this time, the electrolytic voltage of the electrolytic cell is reduced to 1.797V@1000mA / cm 2 .

Embodiment 3

[0043] A gas diffusion layer electrode was prepared on the basis of carbon paper. In this electrode, the mass ratio of catalyst to Nafion was 5:1, and other battery parameters were the same as in Example 1. Figure 5 It is the steady-state polarization curve of the full battery under the same test conditions as Example 1, and the performance of the electrolytic cell is obviously reduced. At this time, the electrolytic voltage of the electrolytic cell is reduced to 1.832V@1000mA / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com