Preparation method of optimized membrane electrode containing anion exchange resin transition layer for electrolysis

A technology of anion exchange membrane and exchange resin, applied in the direction of electrode shape/type, fuel cell parts, etc., can solve the problems of high price, achieve the effect of improving performance, wide application value, and reducing ohmic drop loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

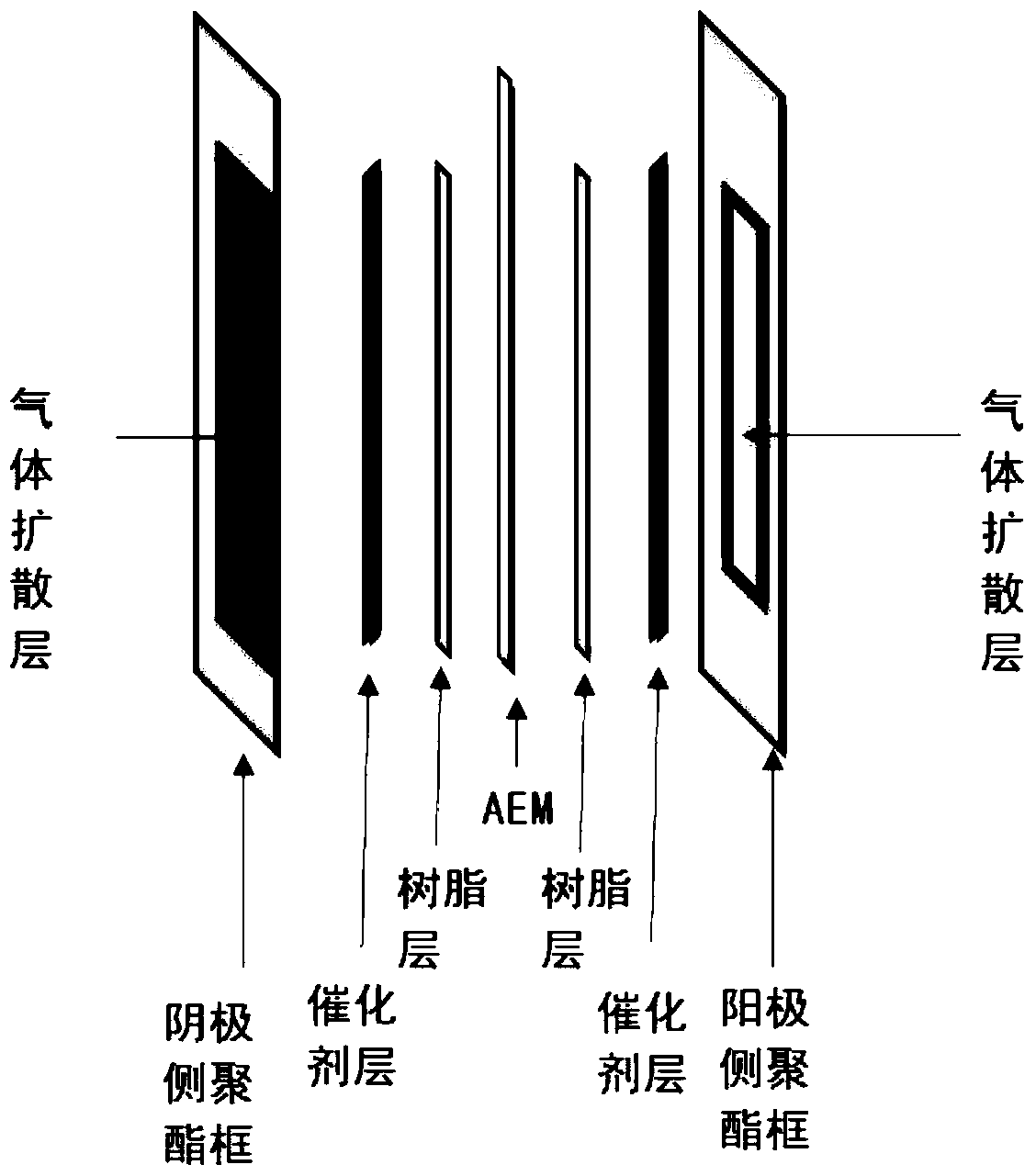

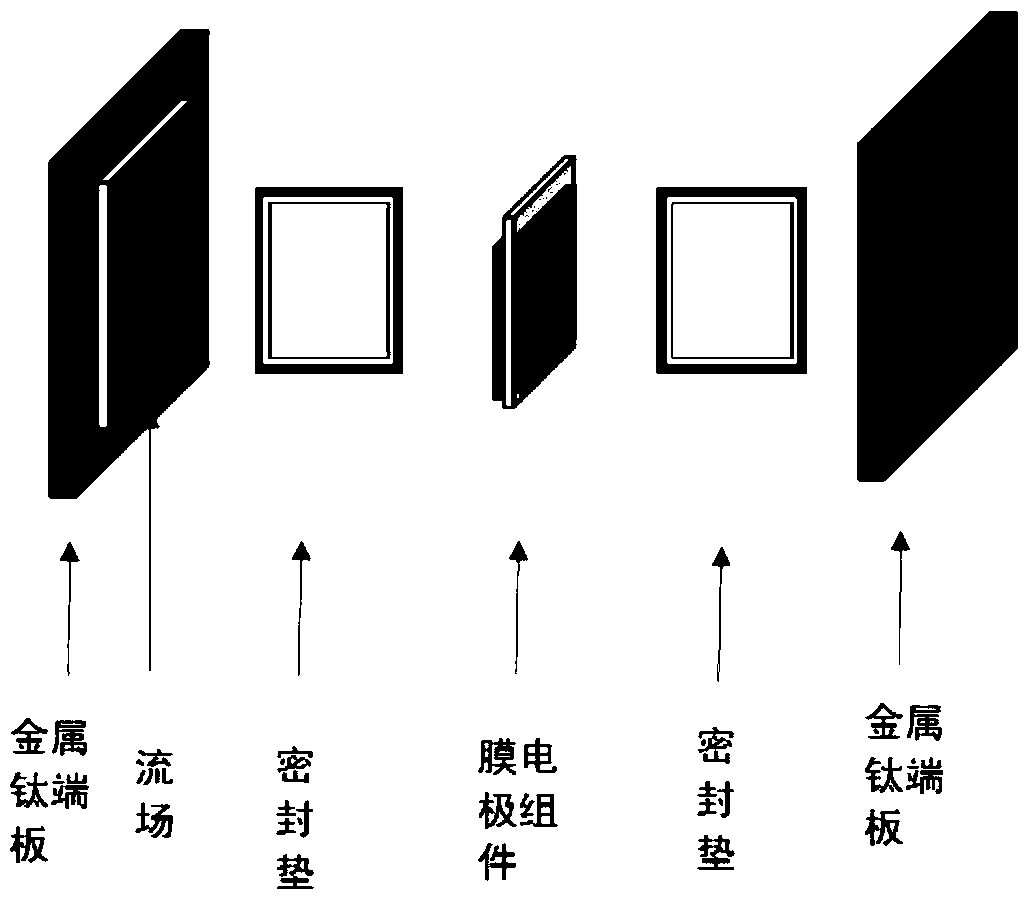

[0032] (1) Preparation of catalyst slurry: First weigh 93 mg of Ir black and 62 mg of 70 wt.% Pt / C, and then mix a certain amount of ethanol according to the mass ratio of catalyst and anion exchange resin (AS-4) at a ratio of 4:1 , isopropanol or n-propanol, the mass ratio of the catalyst to ethanol, isopropanol or n-propanol is 1:40, and the mixed slurry is ultrasonically mixed for 20min. Then according to the membrane electrode area according to 0.6mg / cm 2 The loading amount of the anion exchange resin was weighed, mixed with ethanol / isopropanol / n-propanol at a ratio of 1:40, and then sonicated for 15 min.

[0033](2) Spraying of catalyst slurry: The ethanol, isopropanol or n-propanol solution of the anion exchange resin prepared in (1) was sprayed on both sides of the anion exchange membrane (A201), and then the ultrasonic The uniform catalyst slurry was sprayed on both sides of the membrane, and the above spraying operations were all carried out on a hot stage, and the t...

Embodiment 2

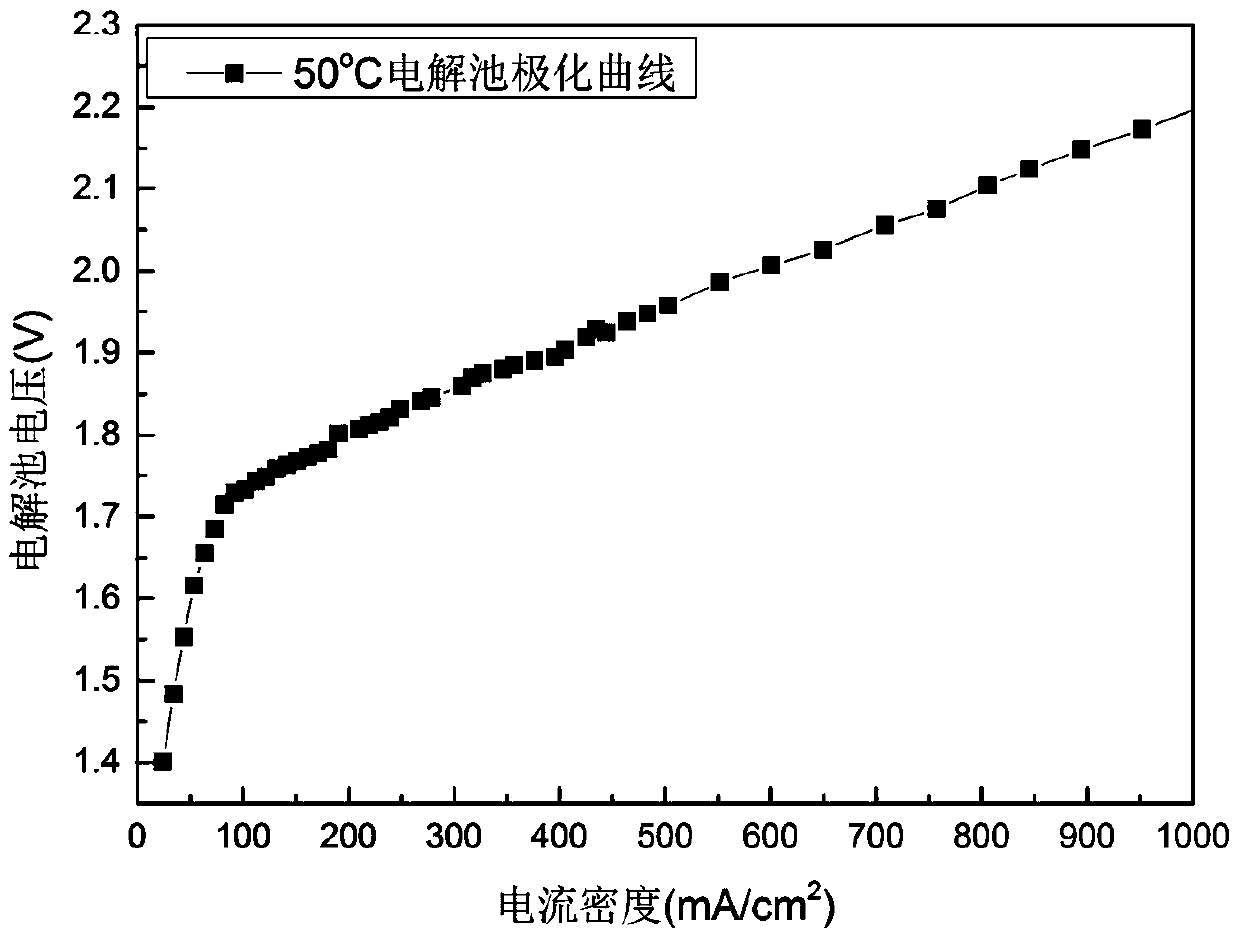

[0038] The same membrane electrode preparation process as in Example 1 was adopted, and the electrolyte of the electrolytic cell was changed from KHCO with a concentration of 1 wt.% 3 The solution was replaced with deionized water, and the full battery was assembled for testing. The relevant test results are as follows: Figure 4 shown.

Embodiment 3

[0040] During the experiment, it was found that the content of resin in the catalytic layer would affect the overall performance of the electrolytic cell. By adjusting the proportions of different components in the MEA preparation process, when the mass ratio of catalyst to resin (AS-4) in the catalytic layer was 5 : 1, the performance of the electrolytic cell has been improved. Figure 5 is the steady-state polarization curve of the full cell under the same test conditions as Example 2. At this time, the electrolysis voltage of the electrolytic cell was reduced to 1.931V@500mA / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com