Method and device for preparing two-component sound-absorbing cotton through electrostatic spinning-dry laying

An electrospinning and dry-laid technology, which is applied in the field of sound-absorbing cotton manufacturing, can solve problems such as general sound-absorbing performance, and achieve better thermal performance, sound-absorbing effects, and good sound-absorbing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

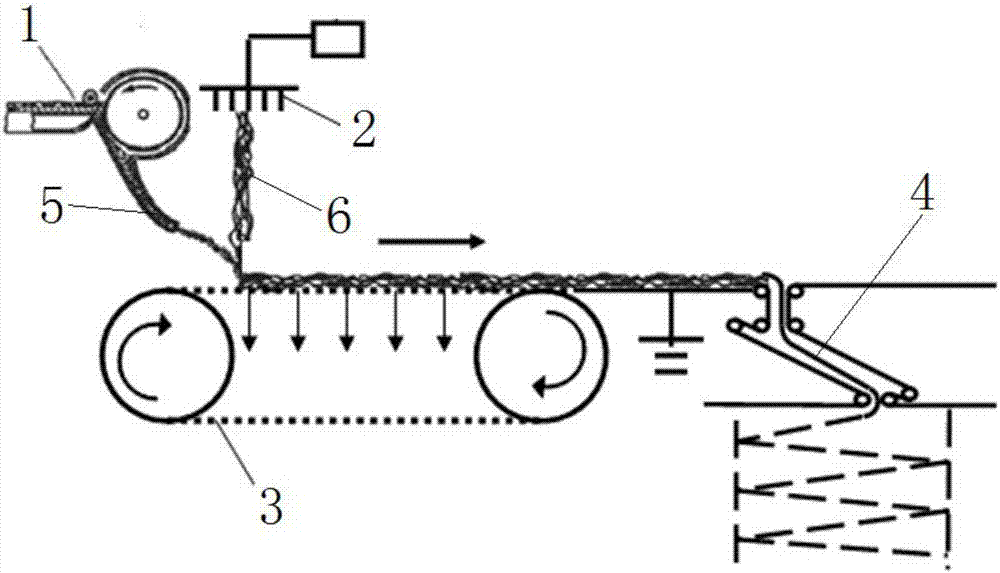

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0031] A method for preparing two-component sound-absorbing cotton by electrospinning-dry method, comprising the following steps:

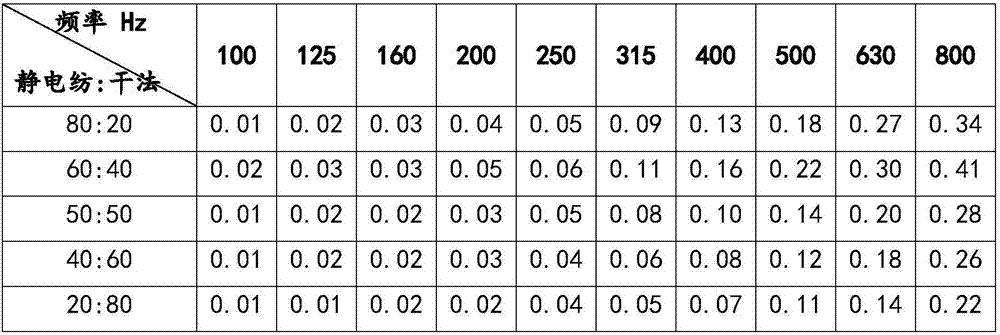

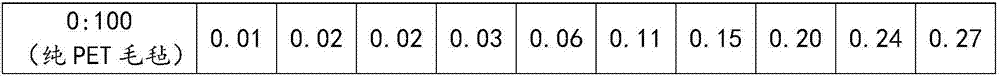

[0032] Step S1, compounding 20-80 parts by weight of electrospun nanofibers and 20-100 parts by weight of dry-laid fibers to obtain an electrospun-dry-laid bicomponent fiber web;

[0033] Step S2, using the electrospinning-dry-laid bicomponent fiber web to cross-laminate to the required square meter grammage, and then perform post-processing to obtain the finished sound-absorbing cotton.

[0034] The weight part of the electrospun nanofiber is 60, and the weight part of the dry-laid fiber is 40.

[0035] The step S1 specifically includes the following steps:

[0036] Step S1.1, prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com