Super-hydrophobic pre-filled gravel sand control pipe and preparation method thereof

A super-hydrophobic, sand-controlling tube technology, applied in earth-moving drilling, mining fluids, coatings, etc., can solve problems such as reduced productivity, reduced permeability of gravel accumulation, and blocked pores of sand-retaining media, to reduce comprehensive water content, avoid The effect of unblocking process and blocking problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

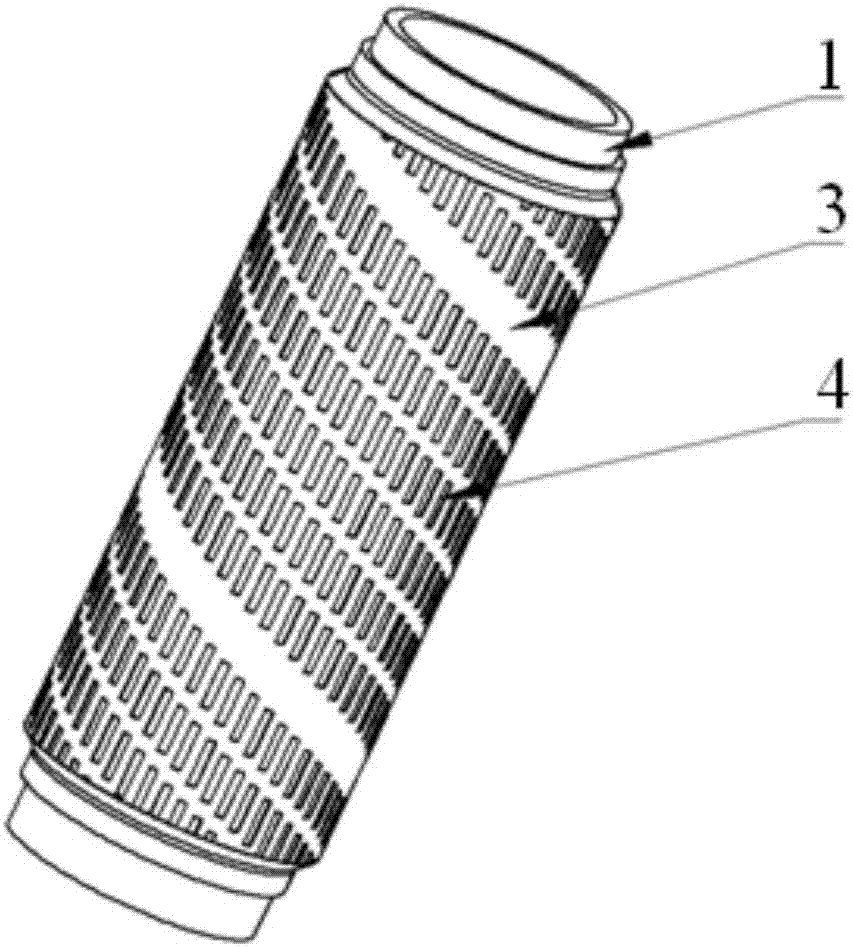

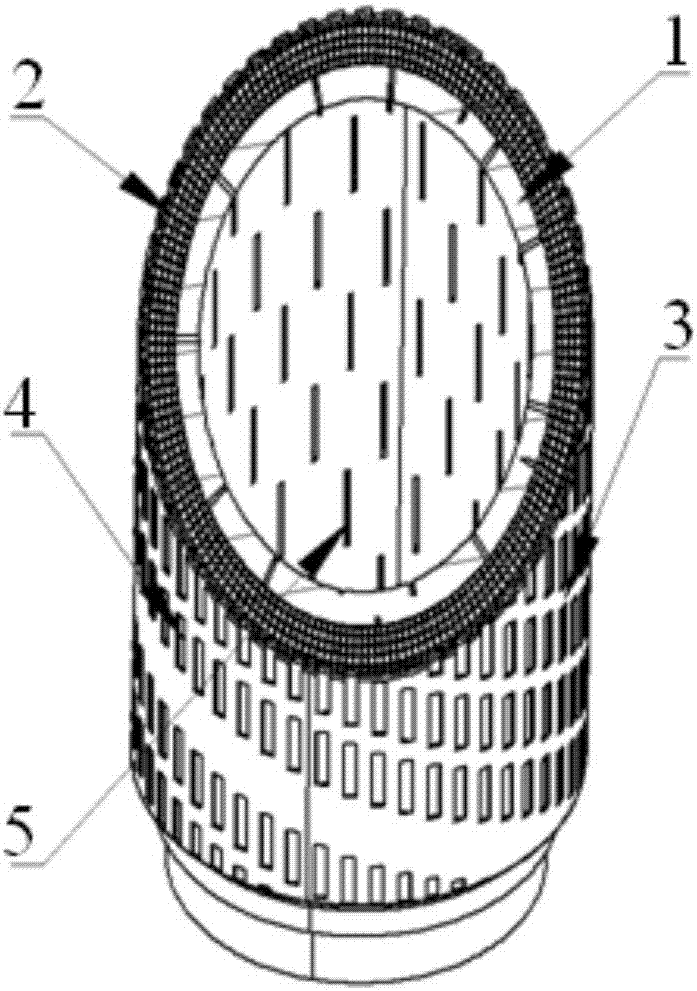

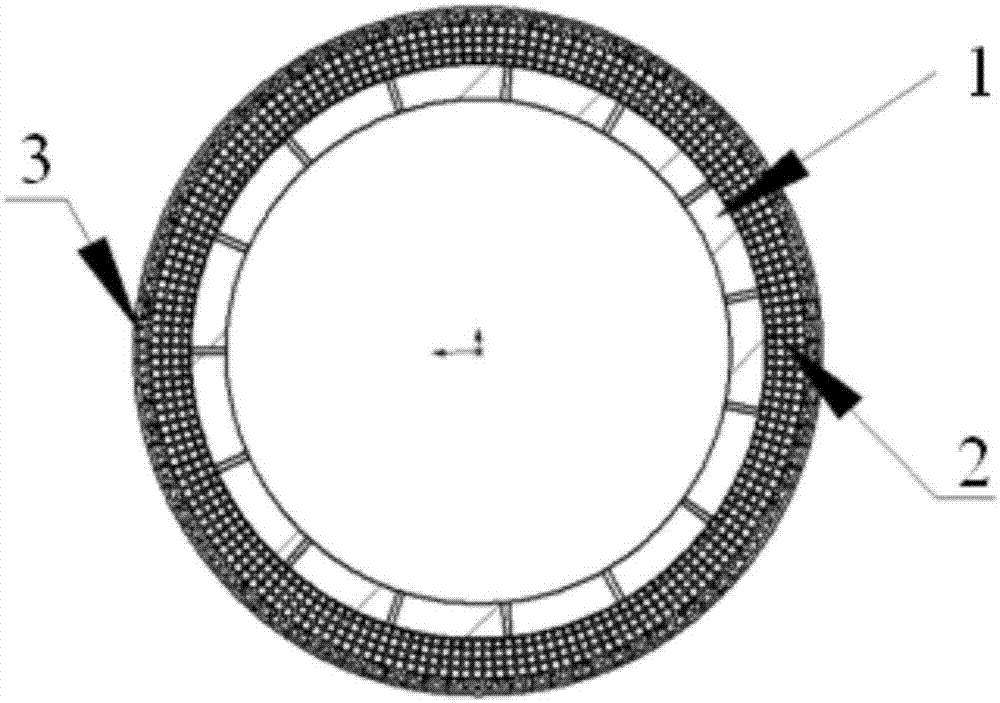

[0054] combine Figure 1 to Figure 3 As shown, the superhydrophobic pre-packed gravel sand control pipe of the present invention includes a base pipe 1, a superhydrophobic sand control pipe shell 3 sleeved on the outside of the base pipe 1 and a superhydrophobic sand control pipe shell 3 filled between the base pipe 1 and the superhydrophobic sand control pipe shell 3 The superhydrophobic gravel layer 2 between them, the surface of the superhydrophobic sand control pipe casing 3 has a first superhydrophobic coating, the superhydrophobic gravel layer 2 is formed by superhydrophobic gravel accumulation, and the surface of the superhydrophobic gravel has a second superhydrophobic coating Hydrophobic coating.

[0055] In the present invention, the superhydrophobic sand control pipe shell 3 is a sand control pipe shell with a first superhydrophobic coating on the outer surface; wherein, the surface stable contact angle of the first superhydrophobic coating is greater than 150°, and...

Embodiment 2

[0071] The preparation method of the superhydrophobic prepacked gravel sand control pipe of the present embodiment comprises the following steps:

[0072] 1. Preparation of the first superhydrophobic material

[0073] 8L of ammonia water (concentration: 25-28wt%) was added to 100L of absolute ethanol, and magnetically stirred and mixed for 1 hour to obtain the first mixture.

[0074] 4.5 L of ethyl orthosilicate was added dropwise to the first mixture, and magnetic stirring was continued for 3 h to obtain a second mixture.

[0075] 1 kg of polymethyl acrylate with a particle size of 300 nm was added to the second mixture, and magnetic stirring was continued for 24 hours to obtain a third mixture.

[0076] Add 20 L of polytetrafluoroethylene to the above third mixture, and continue magnetic stirring and mixing for 42 hours to obtain the first superhydrophobic material.

[0077] 2. Preparation of superhydrophobic sand control tube shell

[0078] Use 36wt% hydrochloric acid so...

Embodiment 3

[0091] The preparation method of the superhydrophobic prepacked gravel sand control pipe of the present embodiment comprises the following steps:

[0092] 1. Preparation of the first superhydrophobic material

[0093] 5L of ammonia water (concentration: 25-28wt%) was added to 100L of absolute ethanol, and magnetically stirred and mixed for 1.5h to obtain the first mixture.

[0094] 6 L of ethyl orthosilicate was added dropwise to the first mixture, and magnetic stirring was continued for 2 h to obtain a second mixture.

[0095] 0.5 kg of polymethyl acrylate with a particle diameter of 200 nm was added to the second mixture, and magnetic stirring was continued for 20 h to obtain a third mixture.

[0096] Add 10 L of polytetrafluoroethylene to the above third mixture, and continue magnetic stirring and mixing for 48 hours to obtain the first superhydrophobic material.

[0097] 2. Preparation of superhydrophobic sand control tube shell

[0098] Use 15wt% hydrochloric acid solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com