Intelligent range hood

A technology of intelligent range hood and range hood, which is applied in the direction of removing range hood, household heating, lighting and heating equipment, etc., can solve the problems of low current detection accuracy, complicated installation structure, affecting the user experience effect, etc., to improve real-time performance and accuracy, cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

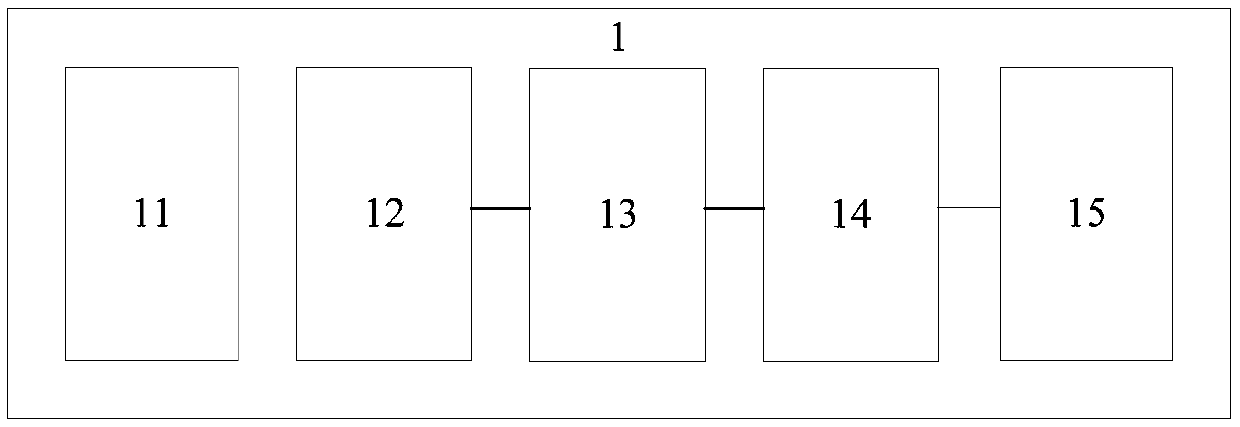

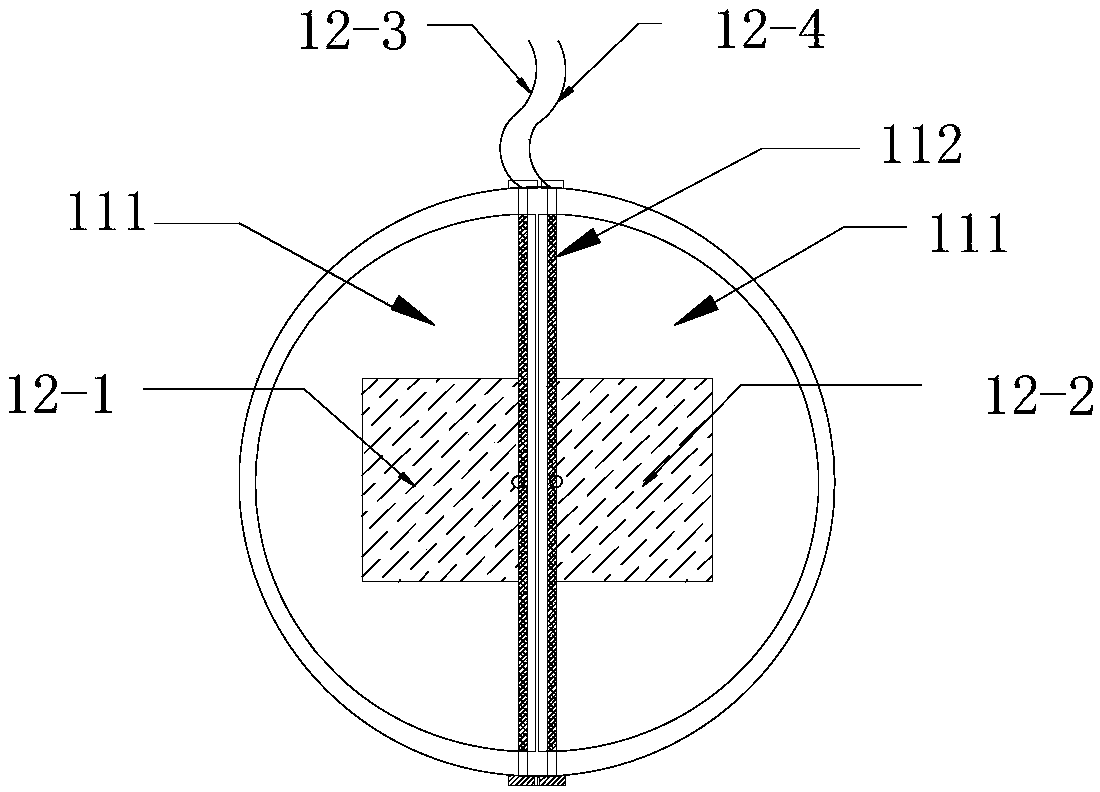

[0060] An intelligent range hood 1, the range hood includes: an impeller, a motor that drives the impeller to run, and a check valve 11 arranged at the air outlet, and also includes: a check valve capacitor unit 12 connected in sequence, an information processing unit 13. Main control unit 14 and motor drive unit 15;

[0061] The check valve capacitance unit 12 is used to generate different capacitances according to the opening and closing of the check valve;

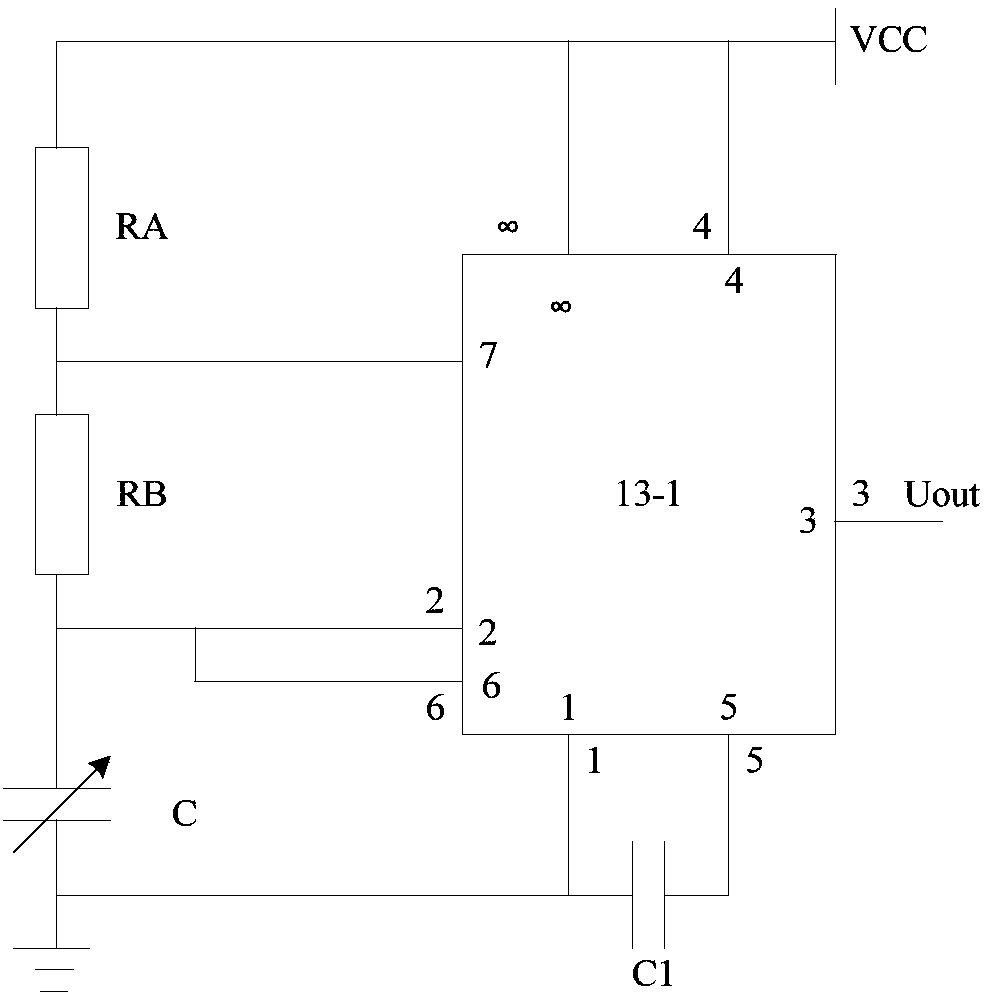

[0062] An information processing unit 13, configured to collect the generated capacitance and convert the capacitance into a rectangular wave;

[0063] The main control unit 14 is used to collect the frequency of the rectangular wave and the current operating state of the range hood, judge the current opening and closing state of the check valve in real time according to the frequency of the rectangular wave and the operating state, and generate different opening and closing states according to different opening and clo...

Embodiment 2

[0100] In this embodiment, on the basis of the first embodiment, the method for the main control unit 14 to judge the opening and closing state of the blades is further refined.

[0101] Optionally, as in Figure 8 As shown, the main control unit is also used to: judge the switching state of the check valve multiple times within a preset time period, so as to confirm the opening and closing state of the check valve;

[0102] Wherein, when the range hood is in the running state, the frequency of the rectangular wave is compared with the preset third frequency to determine whether the check valve is in the normal open state; the third frequency is equal to the first frequency and the preset floating threshold sum; the floating threshold is a positive number;

[0103] When the range hood is in a non-operating state, comparing the frequency of the rectangular wave with a preset fourth frequency to determine whether the check valve is in a normally closed state; the fourth frequen...

Embodiment 3

[0111] On the basis of the second embodiment, this embodiment provides a specific embodiment scheme for determining the included angle of the blades and adjusting the running state of the motor according to the opening and closing states of the blades.

[0112] Optionally, the main control unit 14 is also used for:

[0113] When the range hood is running and it is determined that the check valve is in an abnormally open state, or when the range hood is in a non-operating state and it is determined that the check valve is in an abnormally closed state, according to multiple preset frequency ranges Determine the frequency range of the frequency of the currently detected rectangular wave;

[0114] Judging the angle range between the two blades of the check valve according to the determined frequency range;

[0115] Among them, different frequency ranges correspond to different angle ranges one by one;

[0116] In the embodiment of the present invention, such as Figure 8 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com