Ceramic filter capable of cleaning ceramic fan blades

A ceramic filter and fan blade technology, which is applied in filtration and separation, moving filter element filters, separation methods, etc., can solve the problems of limited adsorption capacity and increase maintenance costs, so as to increase maintenance costs, reduce pipe diameter, and improve cleaning. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

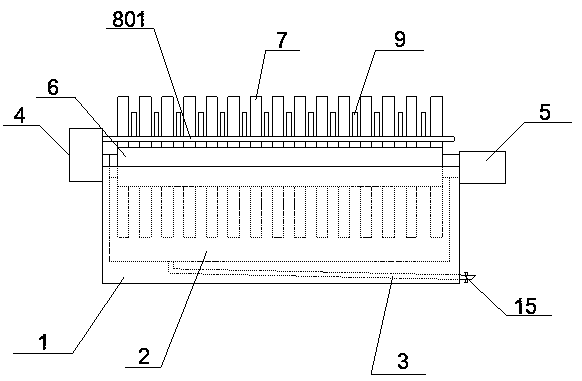

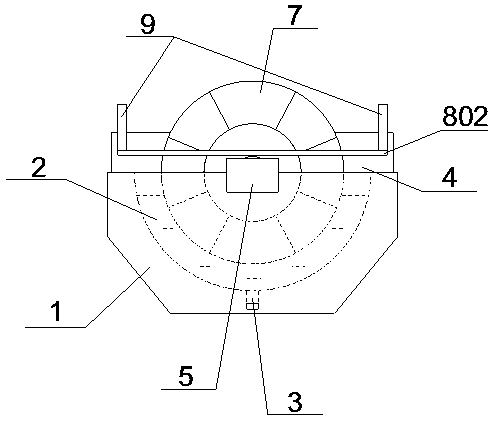

[0031] like Figure 1 to Figure 2 As shown, the ceramic filter capable of cleaning ceramic fan blades includes a drum 6, a motor 5, and a base 1. The base 1 is provided with a slurry pool 2, the drum 6 is connected to the motor 5, and half of the drum 6 is immersed in the slurry pool 2. Multiple groups of ceramic fan blades 7 are evenly spaced on the drum 6 , and the motor 5 is located at one end of the base 1 . The other end of the base 1 is provided with a water tank 4, and the water tank 4 is connected with a water delivery pipe. The water delivery pipe is a closed-loop structure, and the water delivery pipe includes a first horizontal section 801, a second horizontal section 802 and a third horizontal section connected in sequence. The first horizontal section Section 801 and the third horizontal section are parallel to the long side of the base 1, and the first horizontal section 801 and the third horizontal section are located above the base 1, and the first horizontal s...

Embodiment 2

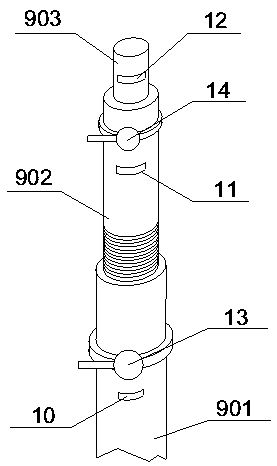

[0034] Based on Example 1, such as image 3 As shown, the water spray pipe 9 includes a first water spray pipe 901, a second water spray pipe 902 and a third water spray pipe 903 from bottom to top, the first water spray pipe 901 is provided with a first water outlet 10, and the second water spray pipe 901 The water pipe 902 is provided with a second water outlet 11, and the third water spray pipe 903 is provided with a third water outlet 12, and the opening sizes of the first water outlet 10, the second water outlet 11 and the third water outlet 12 increase sequentially, And the opening directions all face the drum 6 .

Embodiment 3

[0036] Based on Embodiment 2, the lower part of the second water spray pipe 902 is provided with threads, and the lower part of the second water spray pipe 902 extends into the first water spray pipe 901 and is connected with the first water spray pipe 901 through threads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com