Metal material cooling device capable of preventing rust

A cooling device and metal material technology, applied in the field of metallurgy, can solve the problems of rising cold water temperature, lower metal material temperature, easy rust, etc., and achieve the effect of avoiding rust

Inactive Publication Date: 2018-04-13

重庆琅博宛冶金材料有限公司

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, cold water is generally used for cooling. During the cooling process, the temperature of the cold water rises and the temperature of the metal material decreases. The surface of the metal material is in contact with the cold water and the oxygen in the air at the same time, which is very easy to rust.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

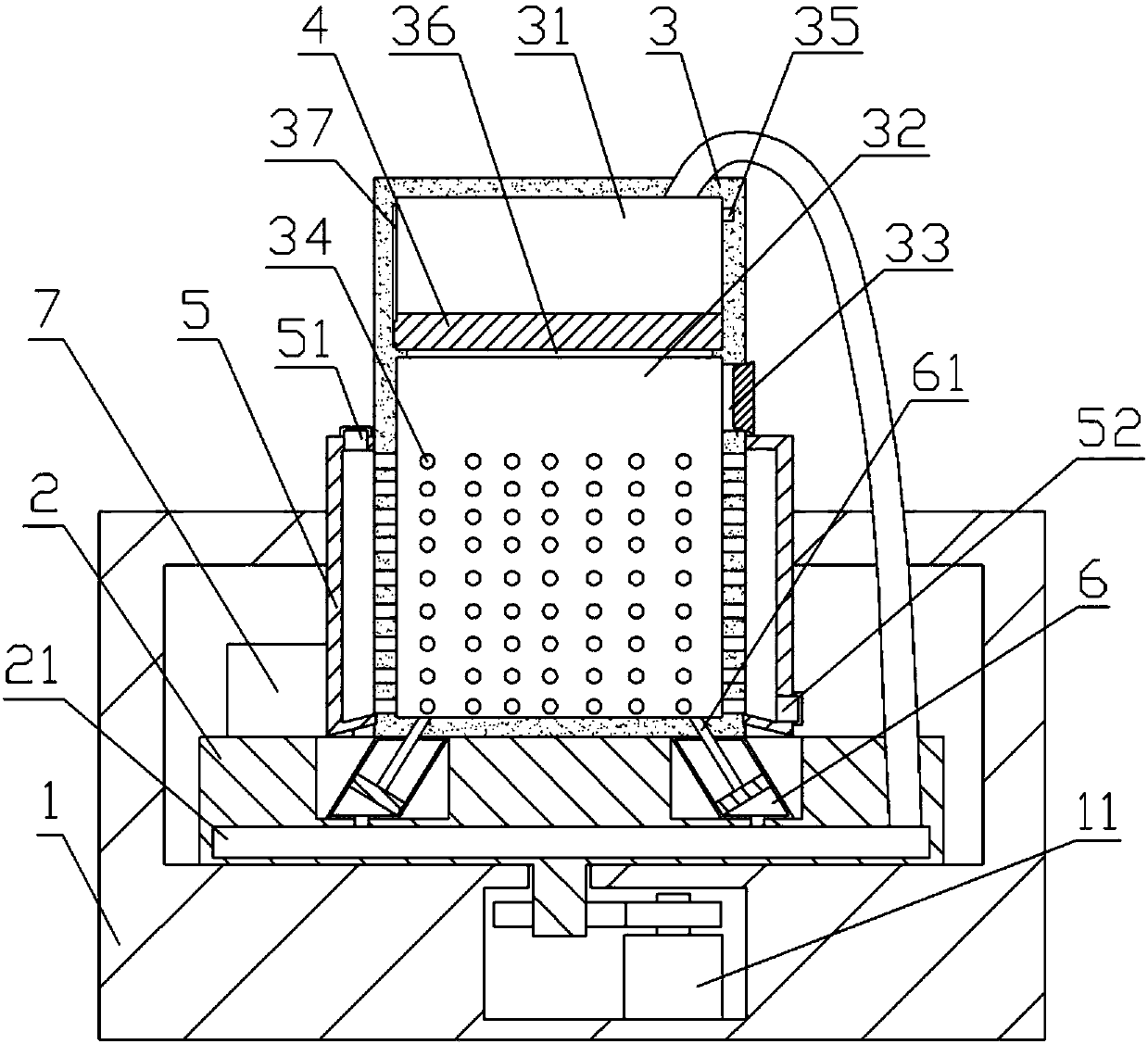

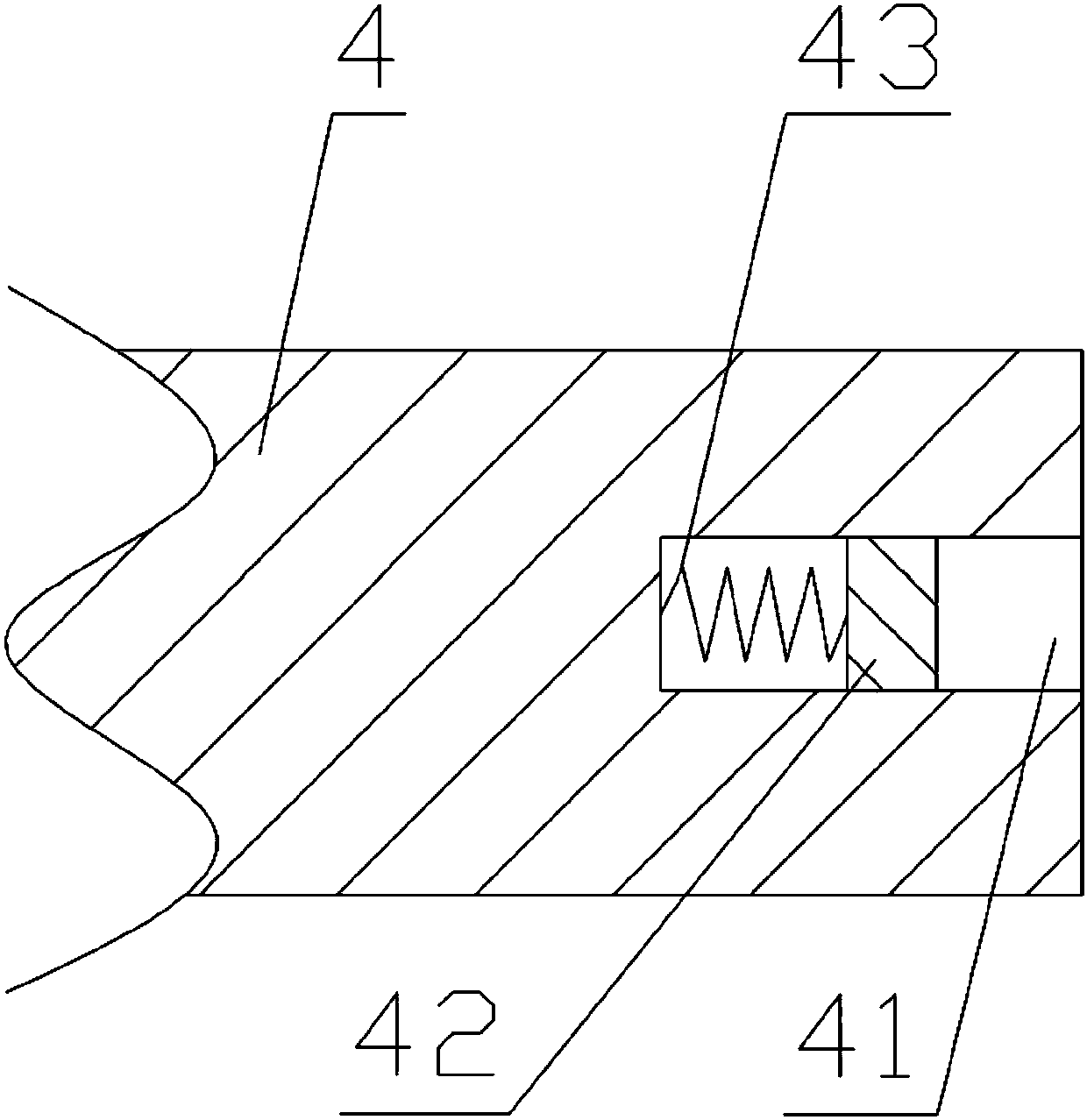

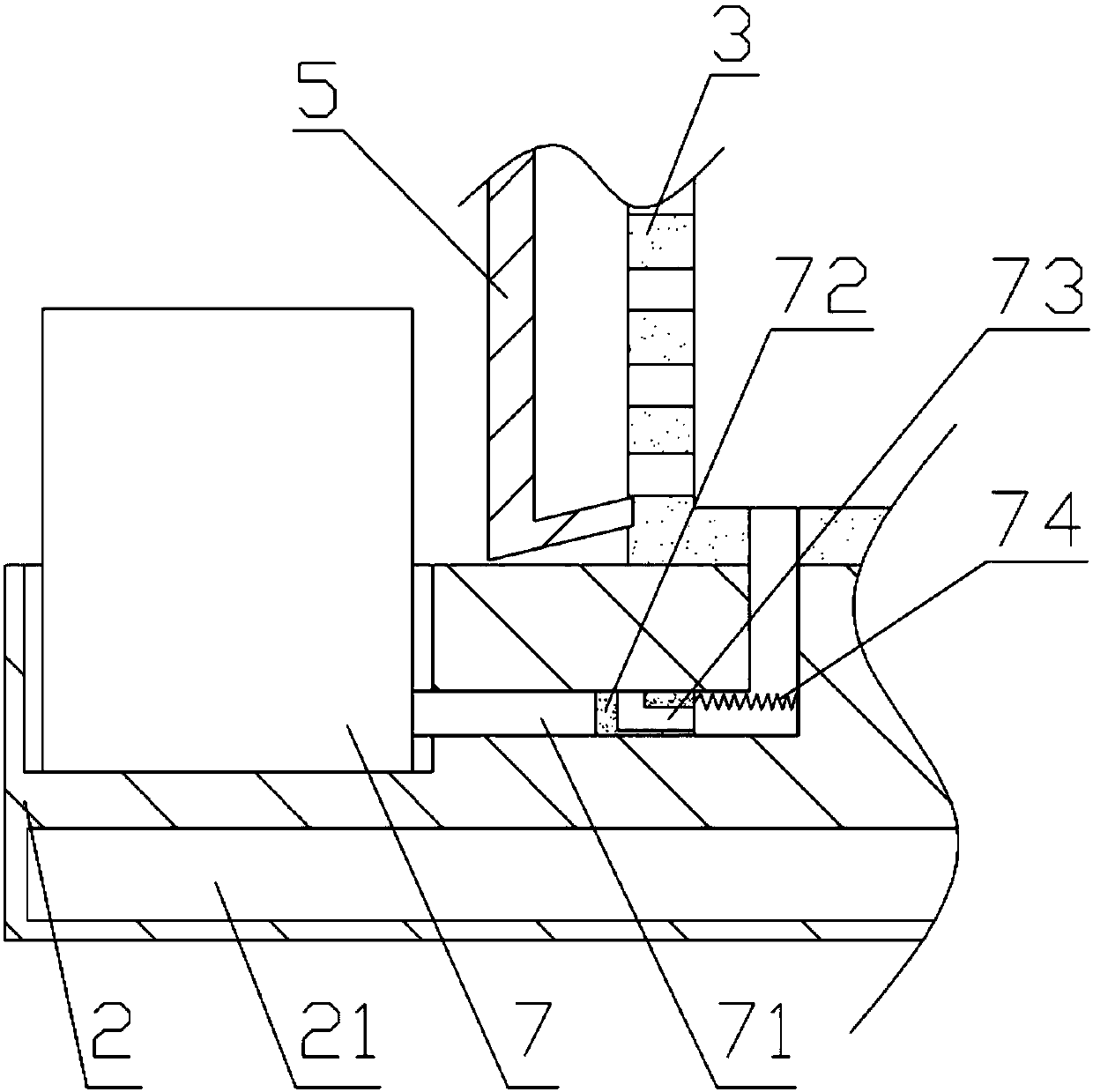

The invention relates to the field of metallurgy, and particularly discloses a metal material cooling device capable of preventing rust. The metal material cooling device comprises a rack, a cooling mechanism and a fixed mechanism; the cooling mechanism comprises an outer barrel and an inner barrel, the outer barrel is located on the outer circumference of the inner barrel, and a motor is fixed tothe rack; the inner barrel is internally provided with a fixed piston, and the fixed piston divides an inner cavity of the inner barrel into a jack-up cavity and a cooling cavity; a clamping groove is formed in the inner wall of the inner barrel, and a groove is formed in the side wall of the fixed piston, and the groove is internally provided with a fixed block and a first spring; a dewatering hole and a feeding opening are formed in the side wall of the cooling cavity; the outer barrel is lower than the feeding opening, and the outer barrel is provided with a water inlet and a water outlet;the fixed mechanism comprises air cylinders which are located below the inner barrel and fixed to the inner barrel, and the air cylinders are obliquely arranged; a fixed rod is fixed to a piston of each air cylinder, the upper portion of the fixed rod penetrates through the bottom of the inner barrel, and the jack-up cavity communicates with the multiple air cylinders. The cooling device of the scheme can isolate a metal material from air while conducting cooling on the metal material and can avoid rusting of the metal material.

Description

technical field [0001] The invention relates to the field of metallurgy, in particular to a cooling device. Background technique [0002] Metallurgy is the process and process of extracting metals or metal compounds from ores, and using various processing methods to make metals into metal materials with certain properties. There are various methods of metallurgy, among which the traditional metallurgical method is pyrometallurgy, which is a metallurgical process carried out under high temperature conditions. Part or all of the minerals in the ore or concentrate go through a series of physical and chemical changes at high temperatures to form another form of compound or element, which is enriched in gas, liquid or solid products respectively to achieve the metal and gangue to be extracted and other purposes of impurity separation. [0003] After the metal is extracted, it is necessary to pour the molten metal into the mold, the temperature of the metal is lowered and solidi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22D30/00

CPCB22D30/00

Inventor 胡丰强

Owner 重庆琅博宛冶金材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com