Multifunctional numerical control turn milling combined machine tool

A combined machine tool, multi-functional technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of single turning or milling function, high price, etc., and achieve the effect of reducing floor space and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

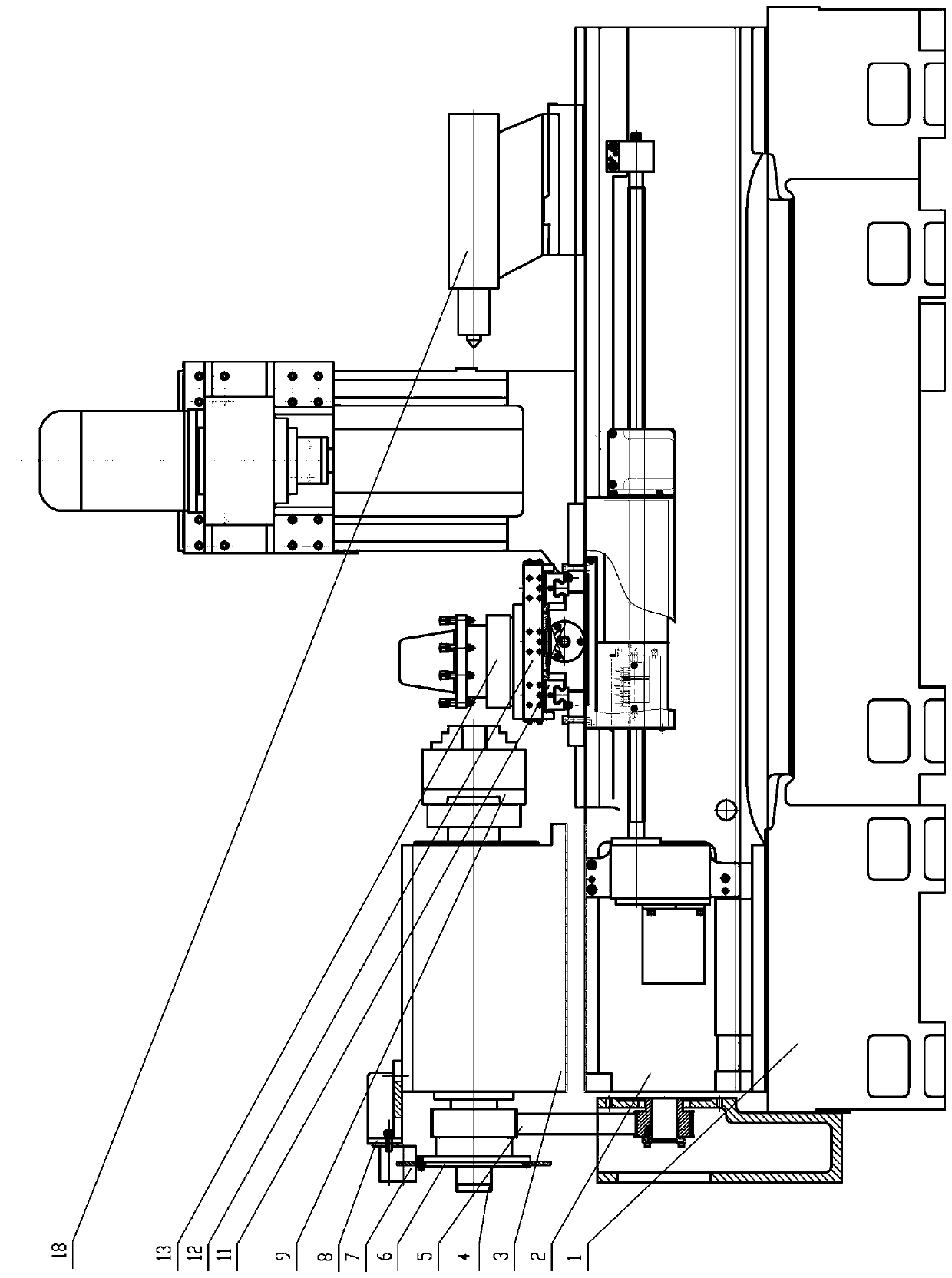

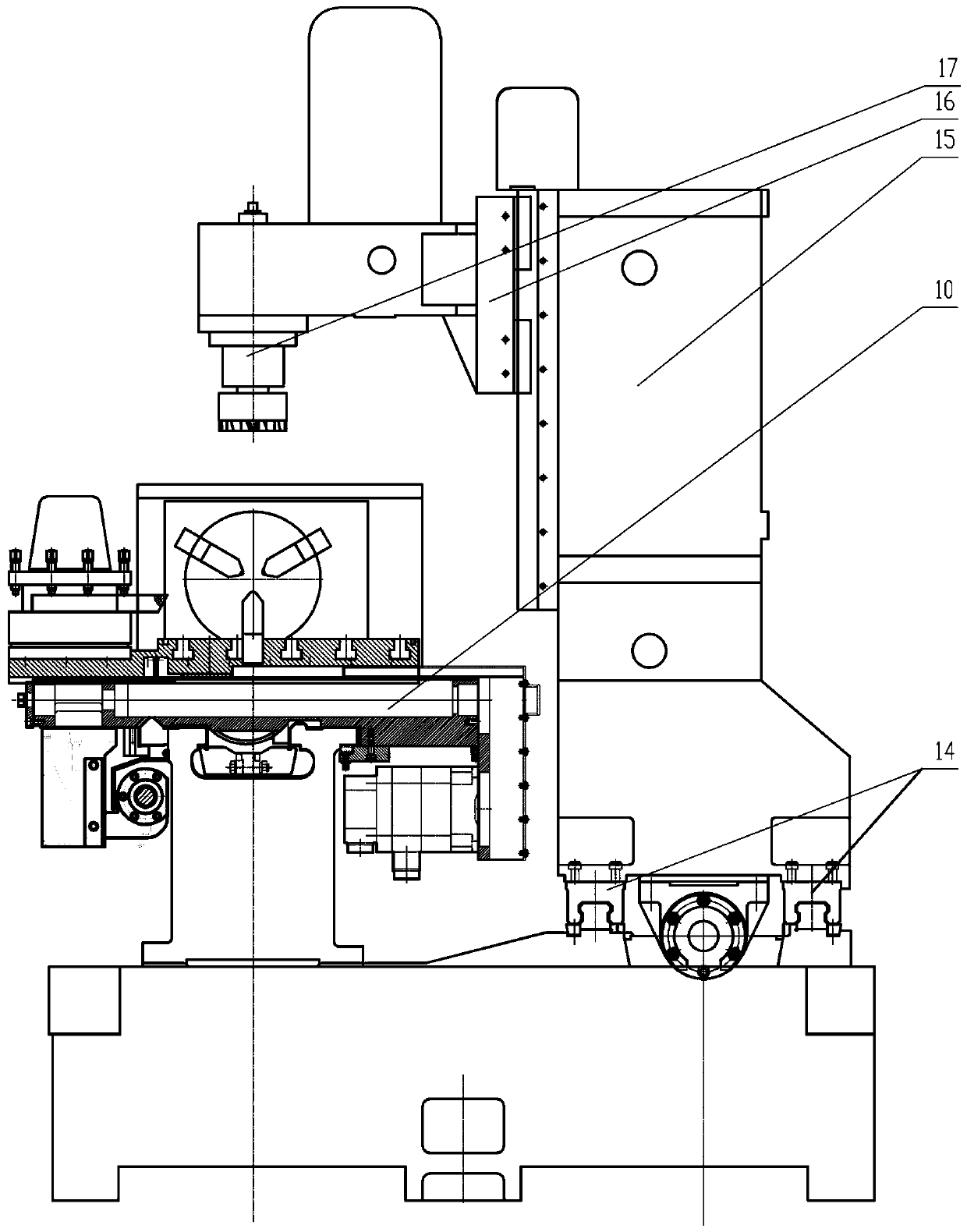

[0017] Attached below Figure 1-2 The present invention will be further described.

[0018] Such as figure 1 As shown, the present invention fixes the flat bed CNC lathe on the front of the base, and the column of the CNC milling machine is installed on the rear of the base, and can move left and right. "Front part" and "rear part" both refer to the "front part" which is closer to the operator and the "rear part" which is farther away from the operator relative to the operator. Milling machine spindle box 16 is housed on the column and moves up and down. This device adopts lathe numerical control system to control the movement of two spindles and four feed axes, and realizes various functions such as turning, milling, grinding, drilling, reaming, turning and milling.

[0019] Such as figure 1 shown. A multifunctional CNC turning and milling combined machine tool structure, comprising a base 1, a lathe bed 2 is installed on the front of the base 1, a lathe headstock 3 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com