Efficient acidic cleaner and preparation method thereof

An acid cleaning agent, high-efficiency technology, applied in the field of cleaning agent, can solve the problems of shortening the service life of the instrument, and achieve the effect of wide application range, low cost and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

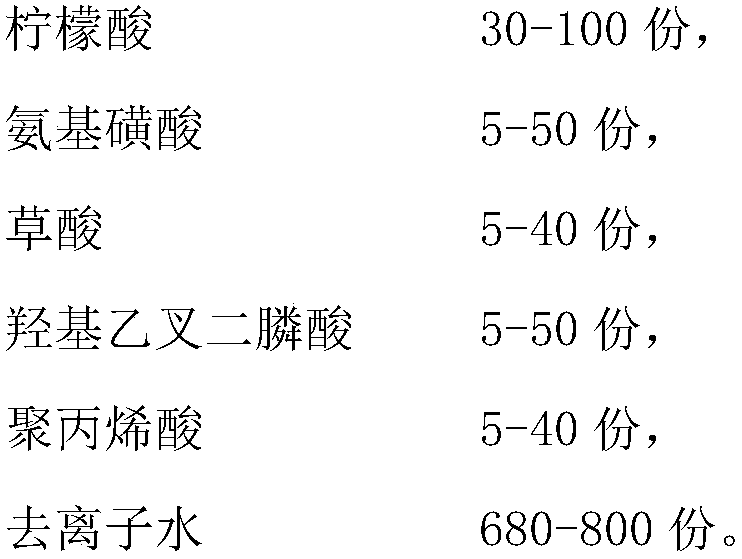

[0027] A high-efficiency acid cleaning agent, consisting of the following components by weight:

[0028]

[0029]

[0030] A preparation method of high-efficiency acid cleaning agent, comprising the following steps:

[0031] 1) Add deionized water, citric acid and sulfamic acid into the reaction kettle, stir for 30 minutes at a temperature of 40°C and a stirring speed of 150 r / min, and dissolve;

[0032] 2) Continue to add oxalic acid, and stir for 10 minutes at a temperature of 40°C and a stirring speed of 150r / min,

[0033] 3) Add hydroxyethylidene diphosphonic acid and polyacrylic acid, and stir for 30 minutes at a temperature of 40° C. and a stirring speed of 150 r / min to obtain a high-efficiency acidic cleaning agent.

Embodiment 2

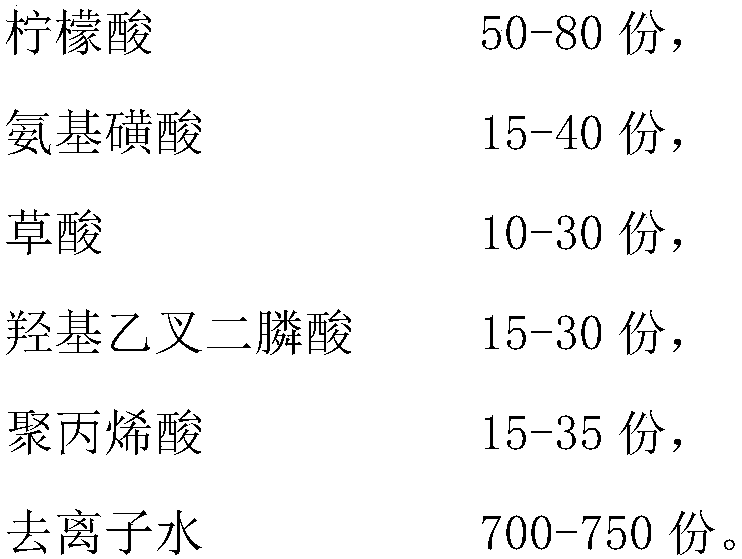

[0035] A high-efficiency acid cleaning agent, consisting of the following components by weight:

[0036]

[0037] A preparation method of high-efficiency acid cleaning agent, comprising the following steps:

[0038] 1) Add deionized water, citric acid and sulfamic acid into the reaction kettle, stir for 20 minutes at a temperature of 45°C and a stirring speed of 200r / min, and dissolve;

[0039] 2) Continue to add oxalic acid, and stir for 10 minutes at a temperature of 45°C and a stirring speed of 200r / min,

[0040] 3) Add hydroxyethylidene diphosphonic acid and polyacrylic acid, and stir for 20 minutes at a temperature of 45° C. and a stirring speed of 300 r / min to obtain a high-efficiency acidic cleaning agent.

Embodiment 3

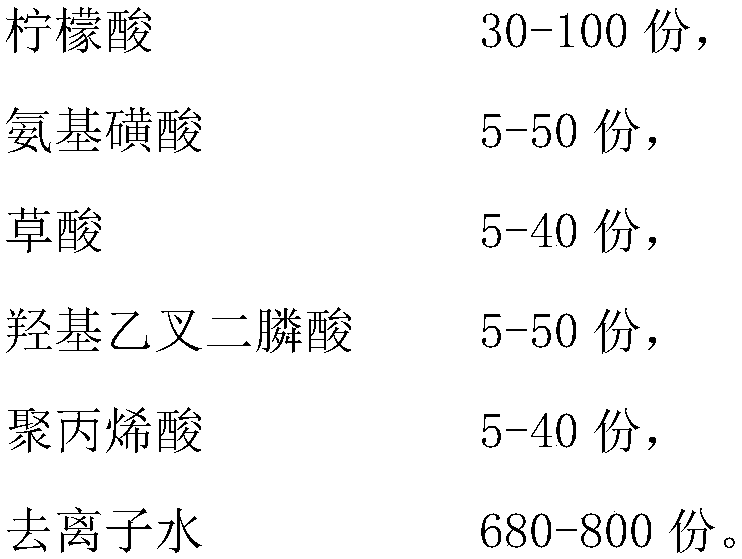

[0042] A high-efficiency acid cleaning agent, consisting of the following components by weight:

[0043]

[0044] A preparation method of high-efficiency acid cleaning agent, comprising the following steps:

[0045] 1) Add deionized water, citric acid and sulfamic acid into the reaction kettle, stir for 20 minutes at a temperature of 50°C and a stirring speed of 250r / min, and dissolve;

[0046] 2) Continue to add oxalic acid, and stir for 20min at a temperature of 50°C and a stirring speed of 250r / min,

[0047] 3) Add hydroxyethylidene diphosphonic acid and polyacrylic acid, and stir for 40 minutes at a temperature of 50° C. and a stirring speed of 150 r / min to obtain a high-efficiency acidic cleaning agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com