Split confined water source hot water supply system

A split-type hot water supply technology, applied in the field of split-type pressurized sewage source hot water supply system, can solve the problems of low heat recovery rate and waste of heat energy, so as to improve heat utilization rate, reduce heat energy loss, and eliminate water pollution. hammer sound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

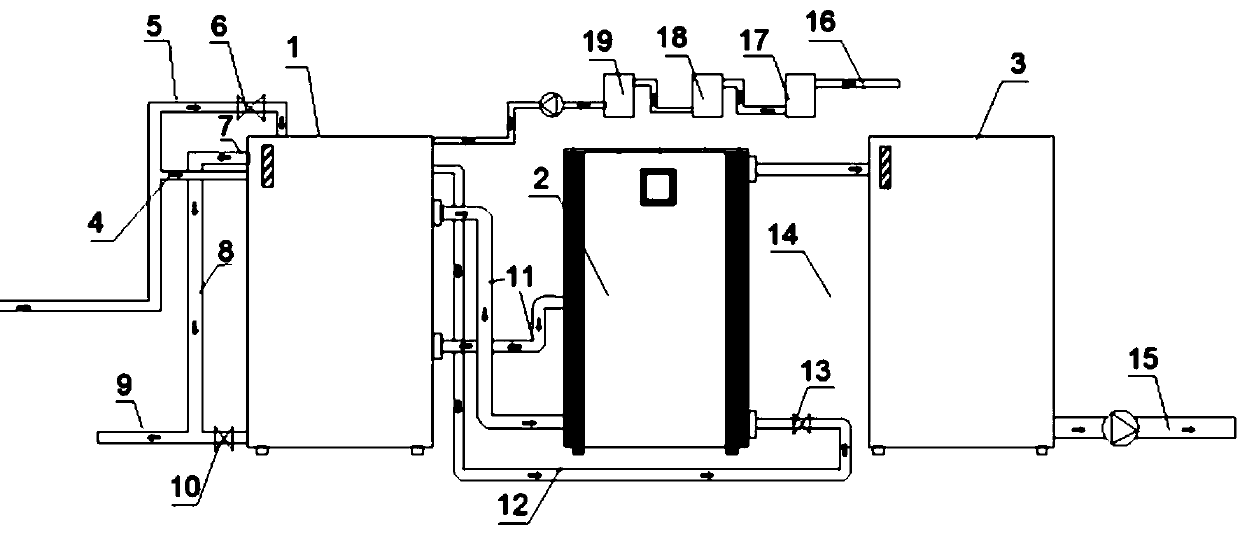

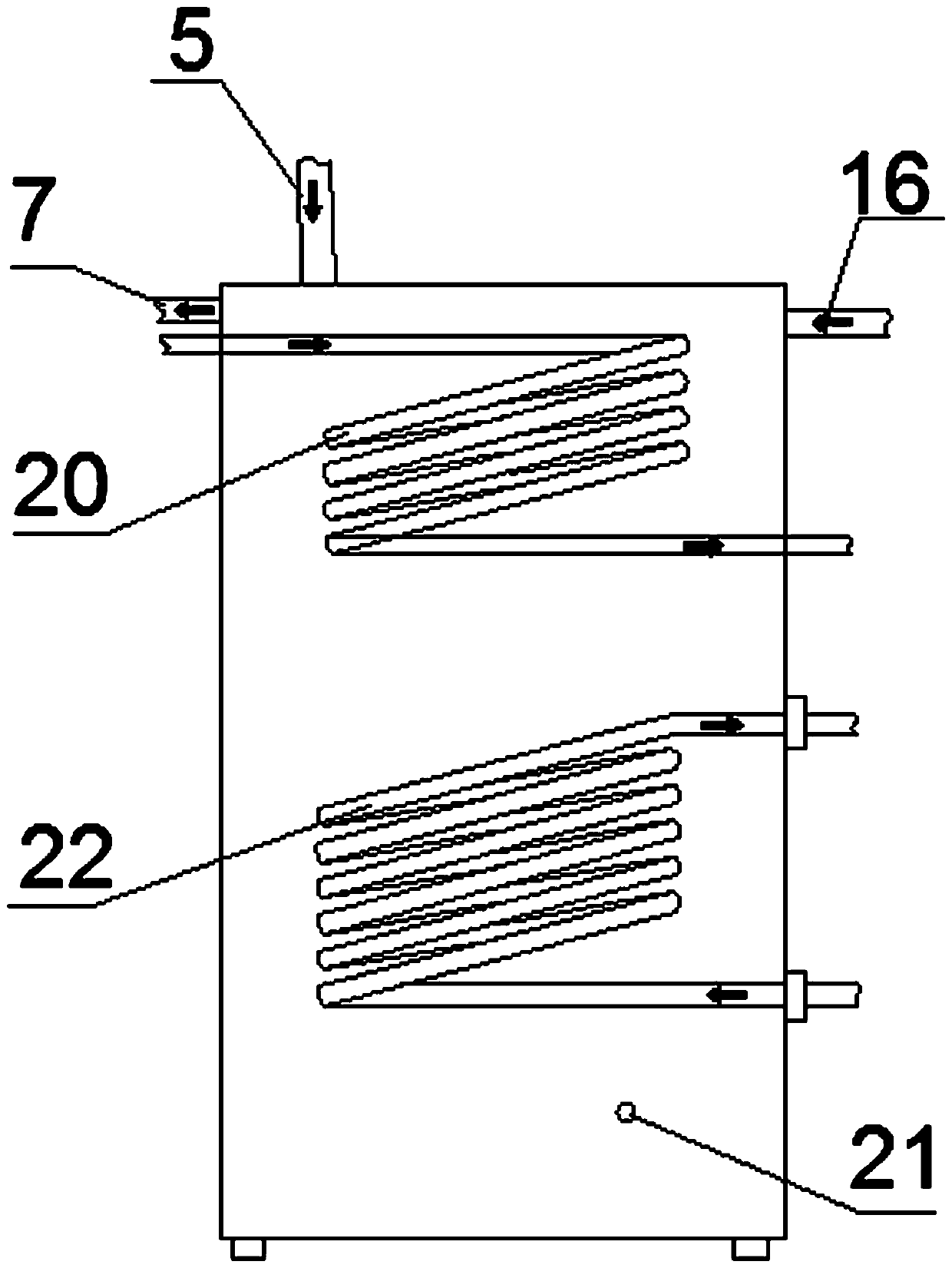

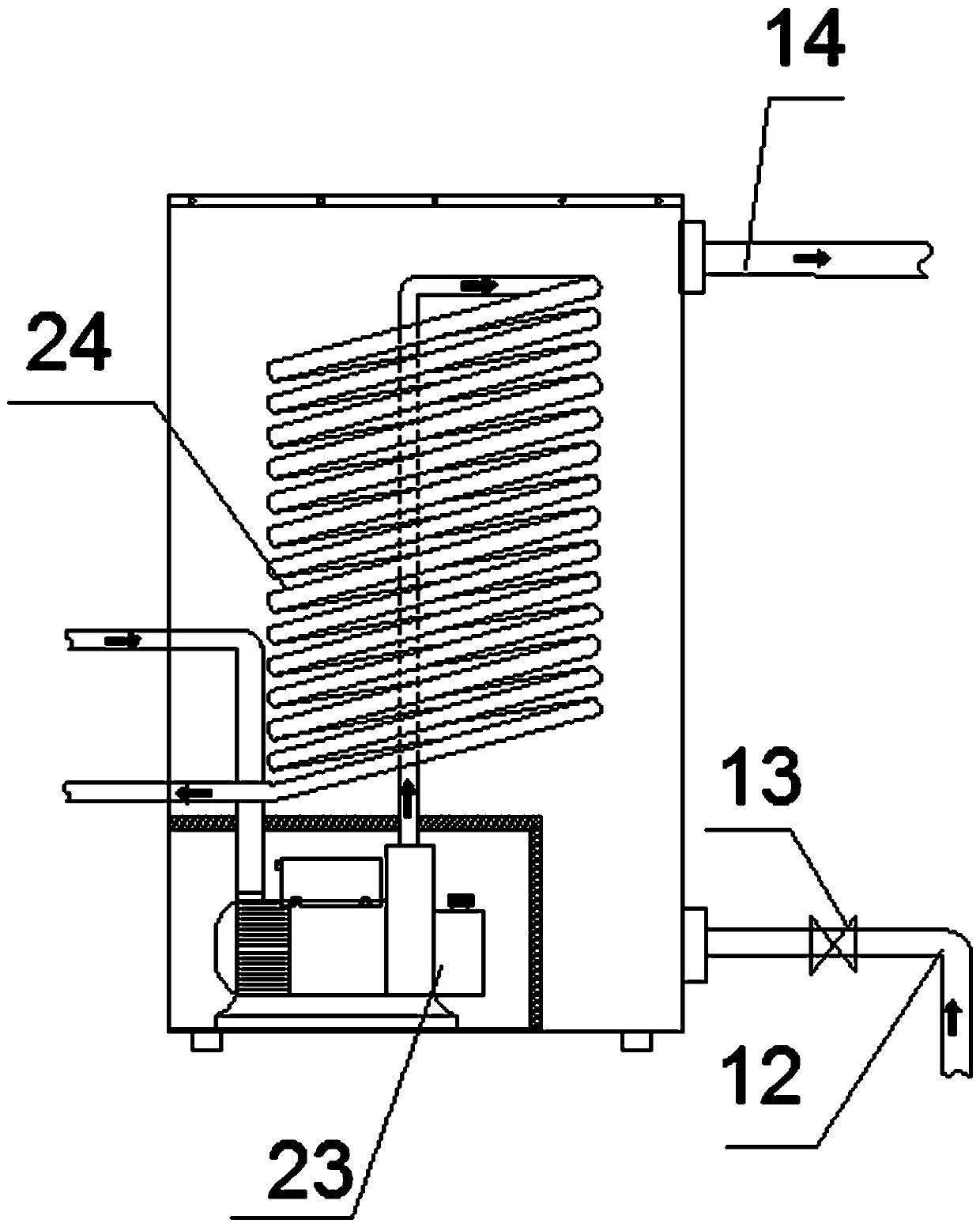

[0024] The split pressurized water source hot water supply system includes: waste water tank 1, main machine 2, hot water storage tank 3, tap water inlet pipe 4, manual water replenishment pipe 5, manual water replenishment valve 6, overflow port 7, overflow water Pipe 8, sewage pipe 9, sewage valve 10, waste water source circulation pipe 11, preheated water inlet pipe 12, replenishment solenoid valve 13, hot water delivery pipe 14, hot water supply pipe 15, waste water recovery pipe 16, sand removal Device 17, oil separator 18, filter 19, waste water tank 1 is equipped with overflow port 7, tap water inlet pipe 4 is divided into tap water inlet pipe 4 and manual water replenishment pipe 5 through a tee, and manual water replenishment valve 6 is installed on manual water replenishment pipe 5 On the top, the tap water inlet pipe 4 and the manual water replenishment pipe 5 are respectively connected to the waste water tank 1, the waste water source circulation pipe 11 and the pre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap