Method of judging morphology of interfacial phase of micro-nano nonuniform material

A non-uniform material, micro-nano technology, applied in the direction of analyzing materials, testing material hardness, sampling, etc., can solve the problems of difficult analysis, the measured results are affected by surface characteristics, and the relative positions are different, so as to improve the experimental accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

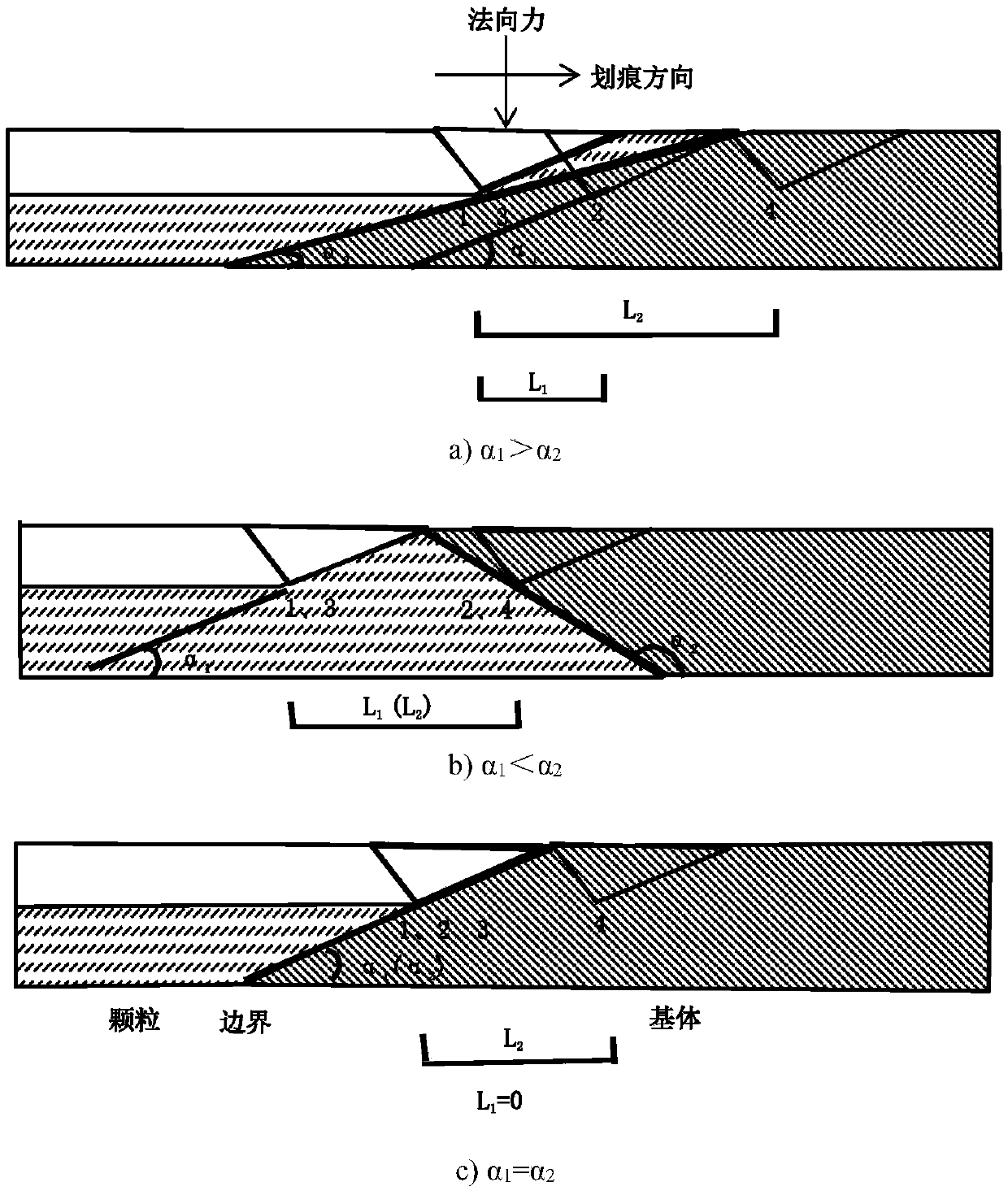

[0024] Example 1 investigates the intermetallic compound Ni 3 Al interface phase morphology

[0025] Using the method of judging the interfacial phase morphology of micro-nano heterogeneous materials to investigate the intermetallic compound Ni 3 The morphology of the Al interface phase, firstly, the typical Ni-Ni 3 Al rectangular mixed area 200 μm x 200 μm. The P value of the feedback adjustment is 10000, the I value is 500, and the D value is 1000. The change speed of the force during the adjustment is ±0.2 mN / s. Set the number of scratches to 11 with an interval of 20 microns. The pre-pressing depth is 1.5 microns, the pressing speed is 0.2 microns / second, and the scratching speed is 4 microns / second. With the bottom left corner of the rectangular area as the zero point, a Cartesian coordinate system is established, and the measured results are imported into origin. According to the judgment criterion of contact mechanics, the position of the starting point and the end...

example 2

[0026] Example 2 investigates the interfacial phase morphology in short carbon fiber reinforced polymethyl methacrylate (PMMA)

[0027] The interface phase morphology of short carbon fiber reinforced polymethyl methacrylate (PMMA) was investigated by using the method of judging the interface phase morphology of micro-nano heterogeneous materials. Rectangular mixing area 200 µm x 200 µm. The P value of the feedback adjustment is 50000, the I value is 100, and the D value is 5000, and the change speed of the force during the adjustment is ±0.5 mN / s. Set the number of scratches to 11 with an interval of 20 microns. The pre-pressing depth is 1 micron, the pressing speed is 0.2 micron / second, and the scratching speed is 5 micron / second. With the bottom left corner of the rectangular area as the zero point, a Cartesian coordinate system is established, and the measured results are imported into origin. According to the judgment criterion of contact mechanics, the position of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com