Method for recognizing partial discharge pattern of gas insulation combined electrical apparatus

A technology of gas insulation combination and partial discharge, which is applied in the direction of testing dielectric strength, etc., and can solve problems such as poor environmental noise resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

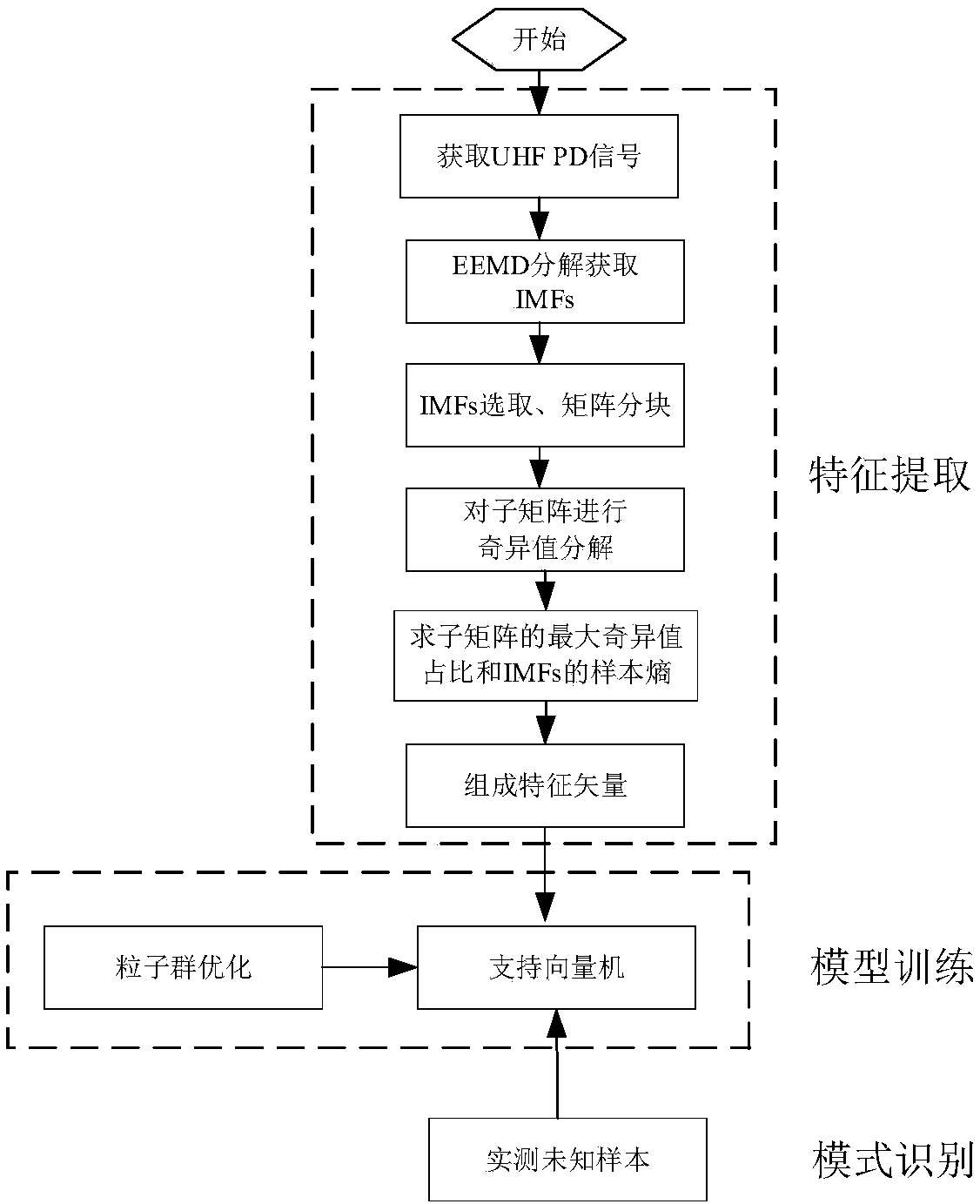

[0058] Process flow of the present invention such as figure 1 As shown, the specific processing steps are as follows:

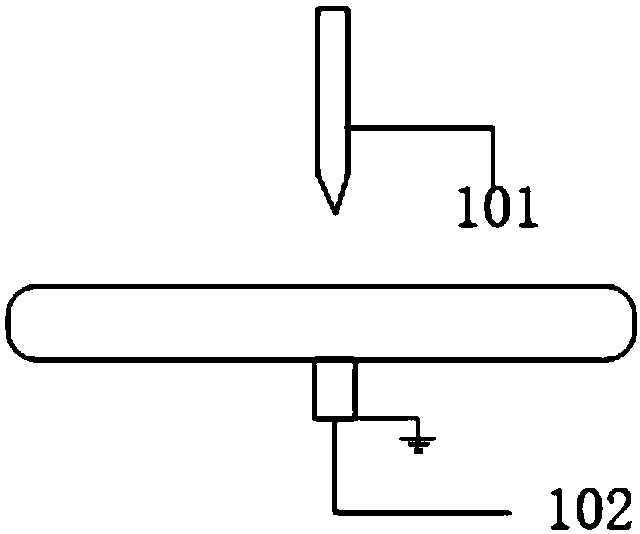

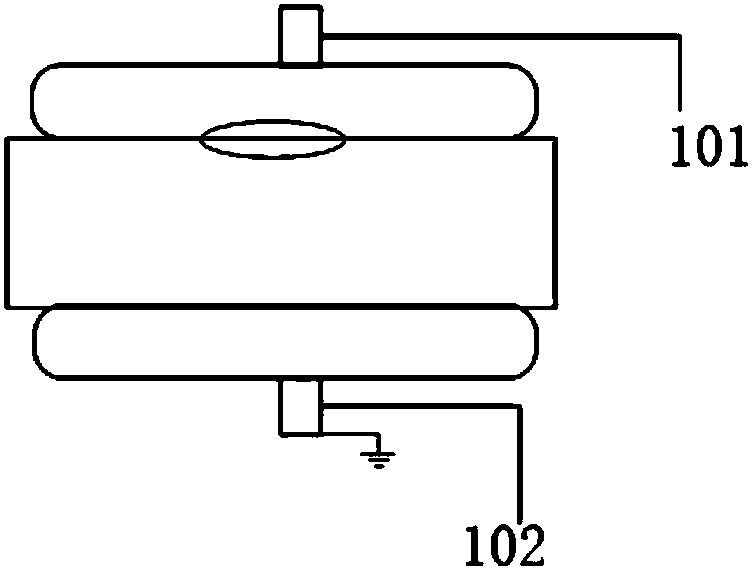

[0059] S1, establish the partial discharge model of different defect types, described partial discharge model has four kinds, as Figure 2 to Figure 5 As shown, they are pin-plate electrode defect model, insulator air gap defect model, insulator surface metal pollution model and free metal particle model;

[0060] Among them, the pin-plate electrode defect model, the insulator air gap defect model, the insulator surface metal pollution model and the free metal particle model all include the aluminum high voltage electrode 101 and the stainless steel ground electrode 102; in addition, the free metal particle model also includes copper metal particles 103; the insulator surface metal contamination model also includes copper metal contamination 1041.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com