Method for etching heterojunction bipolar transistor base substrate by employing single-layer mask

A heterojunction bipolar and transistor technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of wasted cost and disconnection of vapor-deposited gold wires, and achieve the effect of saving mask process, low cost and simple realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

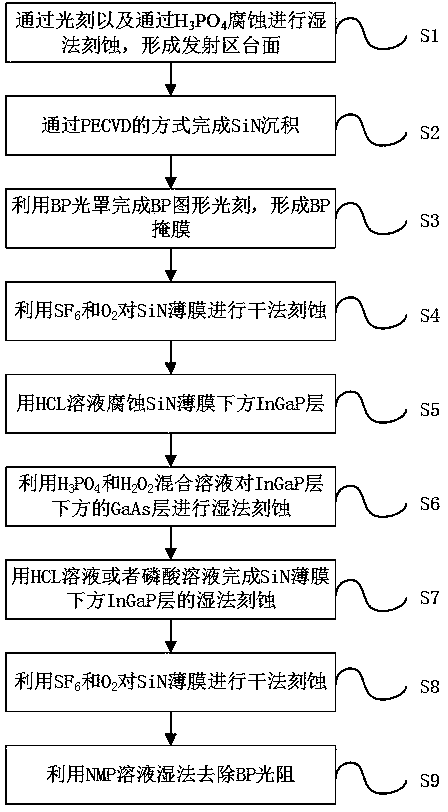

[0025] Describe technical scheme of the present invention in further detail below in conjunction with accompanying drawing: as figure 1 As shown, a heterojunction bipolar transistor base pedestal uses a single-layer photomask etching method, including the following steps:

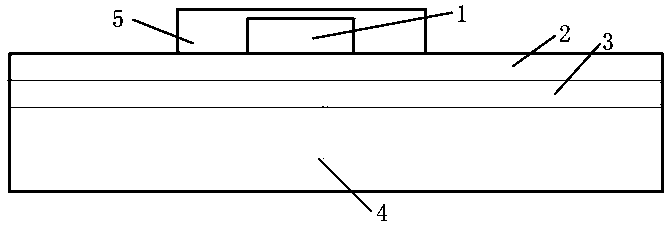

[0026] S1: by photolithography and by H 3 PO 4 Etching is carried out by wet etching to form a mesa in the emission region and form an EM mesa made of GaAs material 1 such as figure 2 shown;

[0027] S2: SiN deposition is completed by PECVD, with a thickness of about 400 angstroms, which acts as a passivation layer, such as figure 2 SiN layer 2 shown in ;

[0028] S3: use the BP mask to complete the BP pattern photolithography to form a BP mask, such as figure 2 BP photoresist 5 shown;

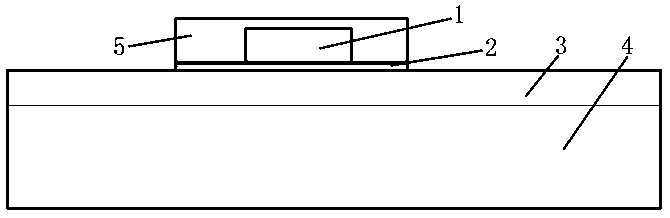

[0029] S4: Utilize SF 6 and O 2 Dry etching of SiN films, such as image 3 shown;

[0030] S5: use HCL solution to etch the InGaP layer 3 under the SiN film, such as Figure 4 shown;

[0031] S6: Use H 3 PO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com