Ultraviolet LED and preparation method

A technology of light-emitting diodes and light-emitting layers, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of limited UVC band effect, no three-dimensional light scattering structure, etc., to improve light extraction efficiency, facilitate light propagation, and facilitate lead wires Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

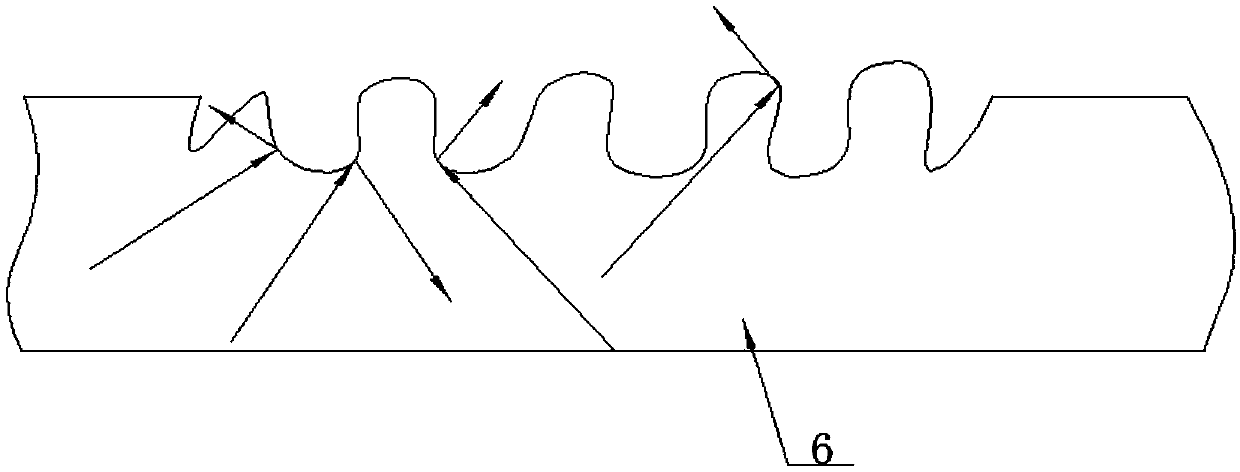

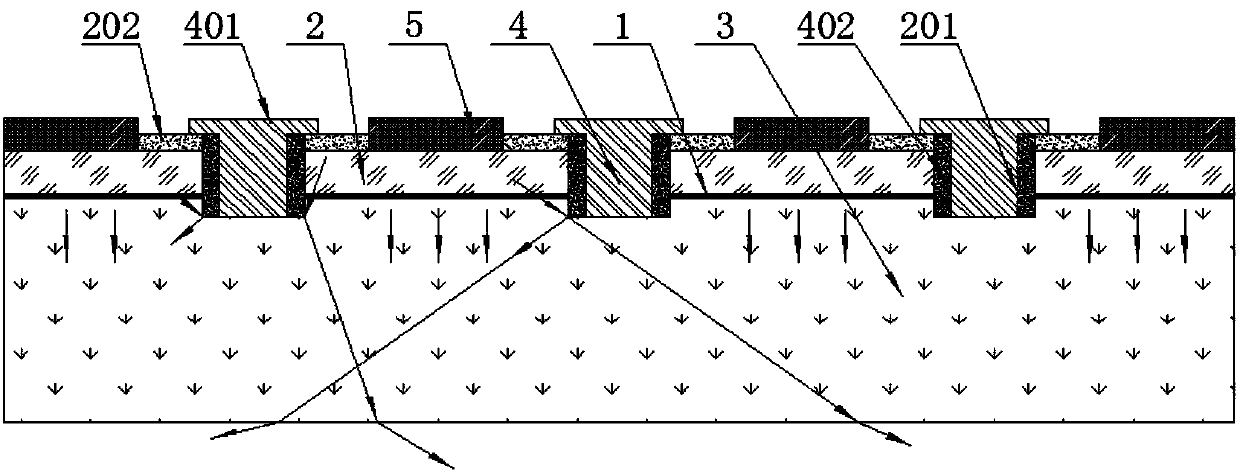

[0027] Such as figure 2 As mentioned above, it is a kind of ultraviolet light-emitting diode, including a light-emitting layer 1, a P-type layer 2 located on one side of the light-emitting layer 1, and an N-type layer 3 located on the other side of the light-emitting layer 1, and a plurality of through-holes are separated on the P-type layer 2. Holes 201, through-holes 201 are periodically and regularly distributed or randomly distributed on the P-type layer 2, the through-holes 201 are circular holes with a diameter of 200nm to 5000nm or square holes or triangular holes or hexagonal holes with a cross-sectional inscribed circle of 200nm to 5000nm , the through holes 201 can reasonably set the N electrode 4, and each through hole 201 penetrates the light-emitting layer 1 downward from the P-type layer 2, and each through hole 201 is provided with an N electrode 4, and one end of the N electrode 4 extends out of the P-type layer 2 An N-terminal electrode 401 is formed. The cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com