Preparation method of shearing type piezoelectric fiber composite material

A piezoelectric fiber, composite material technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, material selection for piezoelectric devices or electrostrictive devices, device material selection, etc., can solve difficult practical applications and other problems, to achieve the effect of clear piezoelectric fiber, simple process flow, and reduced polarization voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

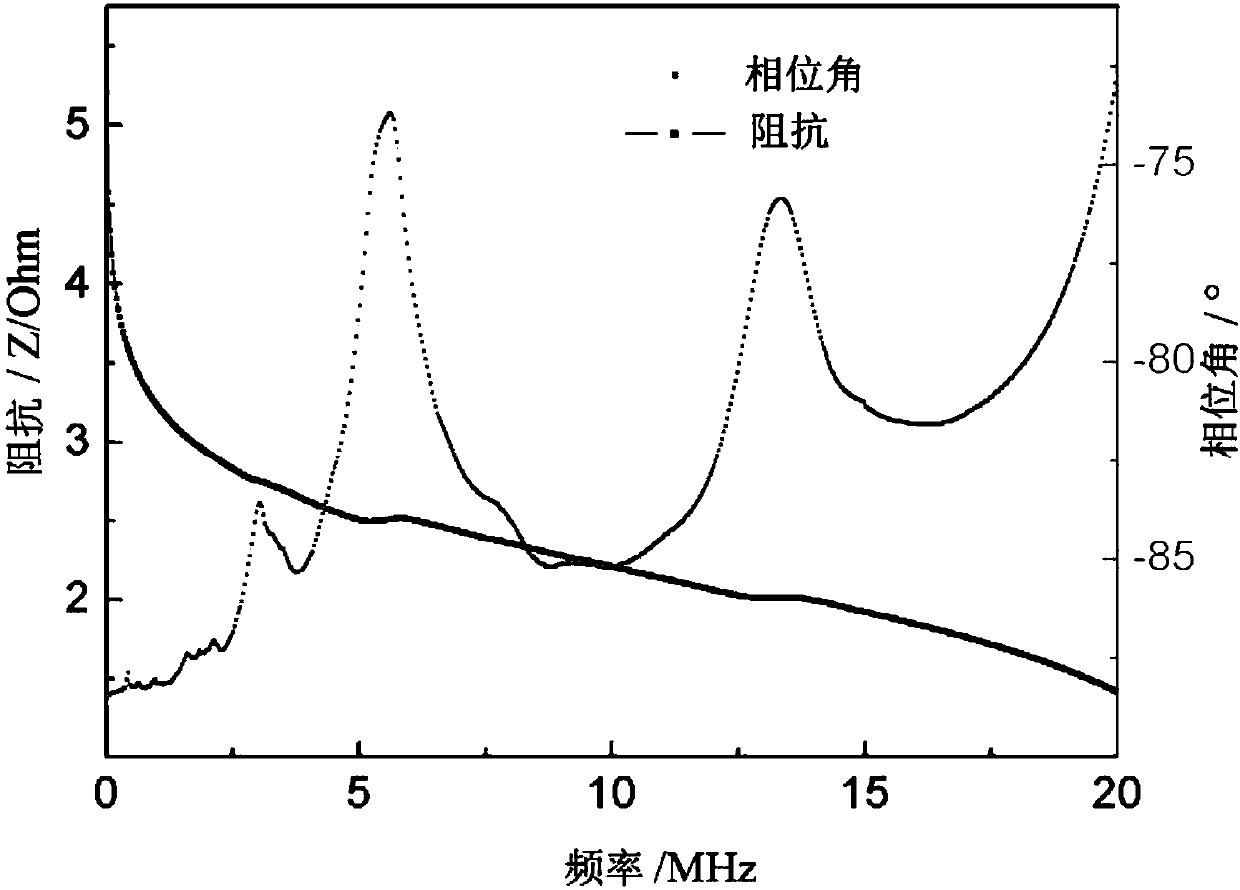

Embodiment 1

[0057] Polarize the PZT-5H piezoelectric ceramic sheet along the thickness direction at a dielectric strength of 2.5kV / mm and a temperature of 80°C for 20 minutes to obtain a lead zirconate titanate piezoelectric ceramic sheet polarized along the thickness direction; after polarization One side of the lead zirconate titanate piezoelectric ceramic sheet is cut with a blade with a thickness of 500 μm to form a plurality of piezoelectric fibers uniformly arranged. The width of the piezoelectric fiber is 690 μm and the thickness is 200 μm. It has fiber gaps, and the width of the fiber gaps is 530 μm.

[0058] Fill the epoxy resin (commodity code is Araldite 2020) in the fiber gap, and then solidify at a temperature of 40°C. After curing, the elastic modulus of the epoxy resin is 3.38GPa, and its Poisson's ratio is 0.27, so that the fiber gap is filled Piezoelectric fibers with epoxy resin.

[0059] The side of the lead zirconate titanate piezoelectric ceramic sheet opposite to th...

Embodiment 2

[0067] The preparation method was the same as in Example 1, except that the thickness of the piezoelectric fiber was 180 μm to obtain a shear-type piezoelectric fiber composite material, and the equivalent material parameters of the piezoelectric fiber composite material were obtained by numerical calculation.

Embodiment 3

[0069] The preparation method was the same as in Example 1, except that the thickness of the piezoelectric fiber was 240 μm to obtain a shear-type piezoelectric fiber composite material, and the equivalent material parameters of the piezoelectric fiber composite material were obtained by numerical calculation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com