Pipe bending machine

A pipe bending machine and pipe bending technology, which is applied in the directions of forming tools, feeding devices, positioning devices, etc., can solve the problems that the pipe bend is not tightly clamped, the pipe fittings are not clamped tightly, and the axial direction of the guide cavity is not parallel to the axial direction. Achieve the effect of improving the quality of elbows, ensuring stability, and ensuring parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

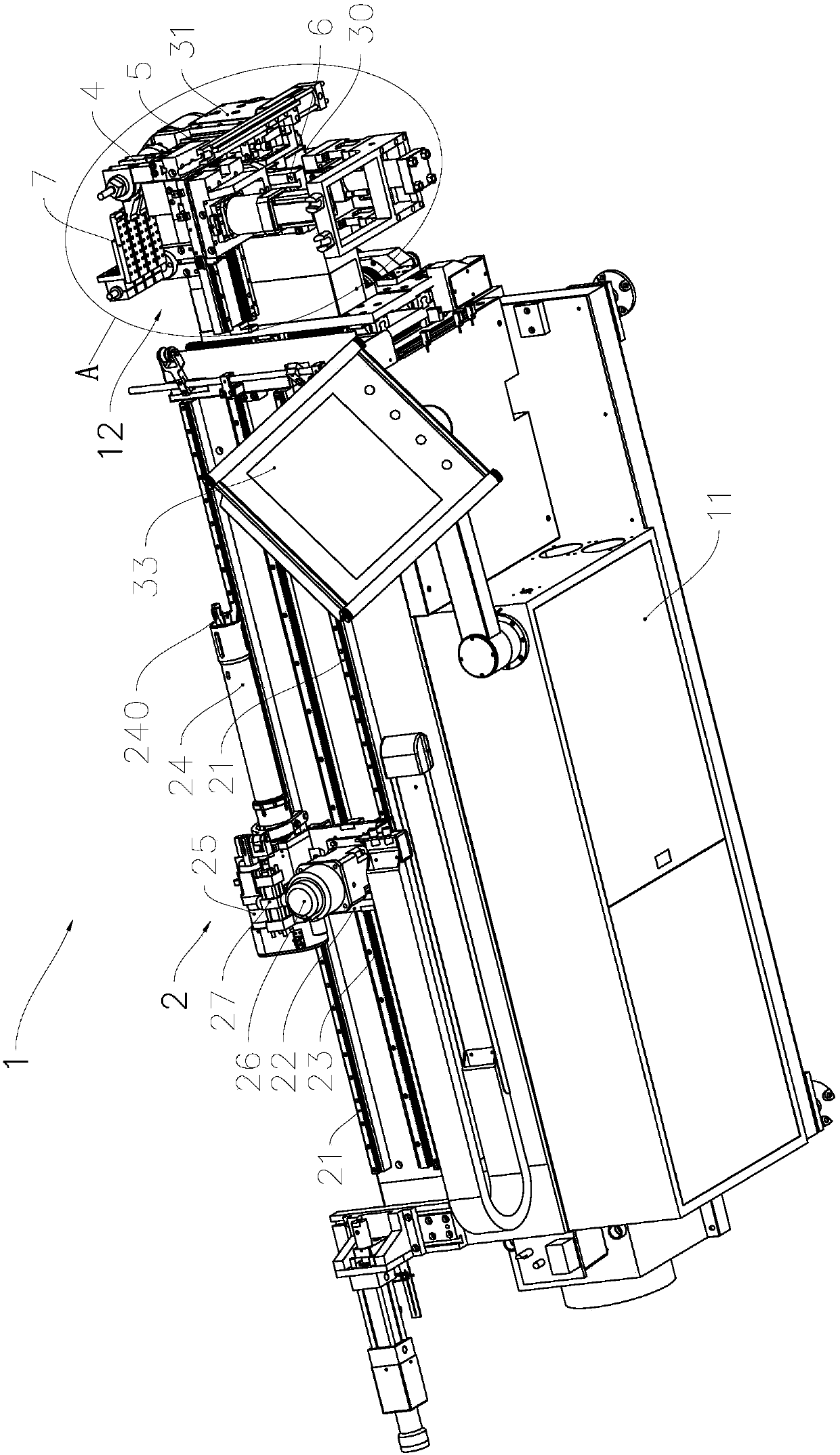

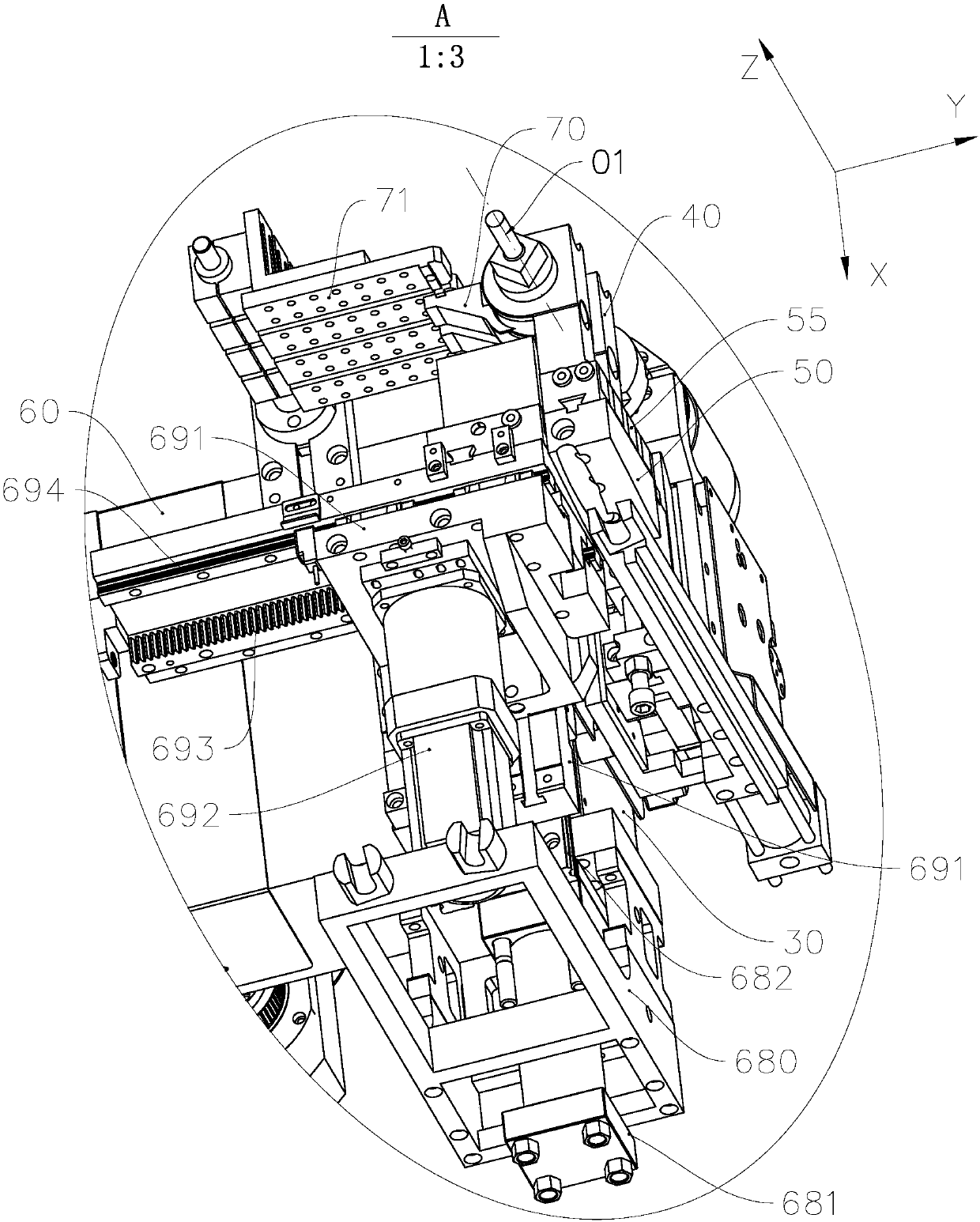

[0036] see Figure 1 to Figure 7 , The pipe bender 1 of the present invention is a numerical control pipe bender, including a frame 11, a control unit, a machine head 12 and a feeding trolley 2 installed on the frame 11 and controlled by the control unit. The machine head 12 includes a mounting seat 30, a swing arm 31, a round die assembly 4, a clamping die assembly 5, a mold guide unit 6, an anti-wrinkle unit 7, and the swing arm 31 is driven to rotate synchronously with the round die assembly 4 through the same drive spindle. The pipe bending motor 32 that drives the rotation axis 01 of the main shaft to rotate.

[0037] Such as figure 1 As shown, the feeding trolley 2 includes two linear guide rails 21 arranged parallel to each other fixed on the frame 11, and the feeding slide table 22 slidably installed on the linear guide rails 21 is arranged along the length direction parallel to the linear guide rails 21. The feeding rack 23 fixed on the frame 11, the feeding main s...

Embodiment 2

[0047] As a description of Embodiment 1 of the present invention, only the differences from the above-mentioned Embodiment 1 will be described below, that is, this embodiment is based on the above-mentioned Embodiment 1, and the transmission between the bending motor and the drive spindle The connection method is improved, that is, the gear transmission mechanism is used to replace the chain and sprocket mechanism between the two, so as to improve the stability of the product bending quality.

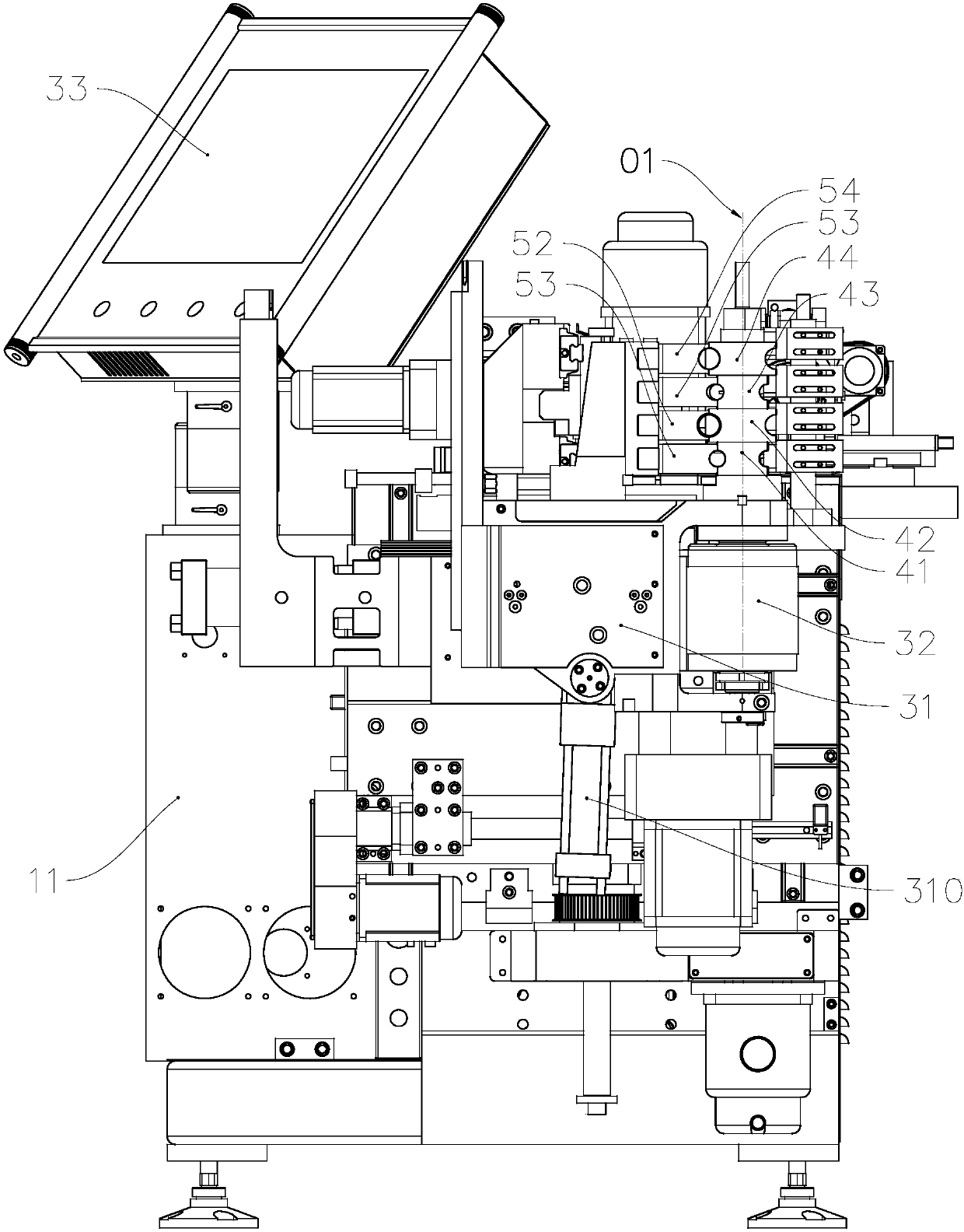

[0048] see Figure 8 to Figure 10 , the mounting seat 30 is a cavity structure with an installation chamber 300, and the gear transmission mechanism is a three-stage gear transmission mechanism, including a main gear 841, a transition gear 857 and a slave gear 875, a primary gap adjustment mechanism and a secondary gap adjustment mechanism; The gap adjustment mechanism includes an eccentric shaft 86 and a locking mechanism; the main gear 841, the transition gear 857 and the slave gear 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com