Method for producing ethylene glycol through hydrolysis of EC (ethylene carbonate)

A technology of ethylene carbonate and ethylene glycol, which is applied in the field of ethylene glycol hydrolysis to produce ethylene glycol, which can solve the problems of easy loss of active components and poor catalyst stability, and achieve the effects of stable properties, poor solution stability and suitable acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

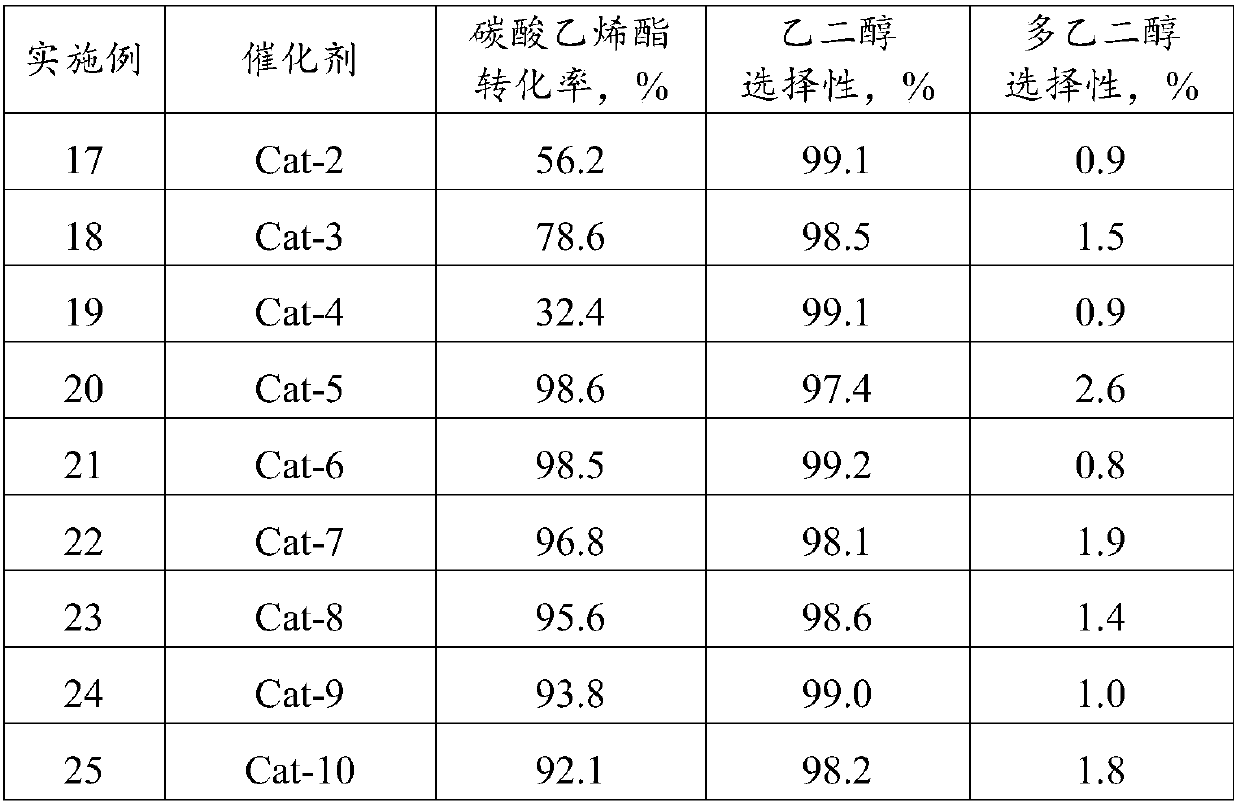

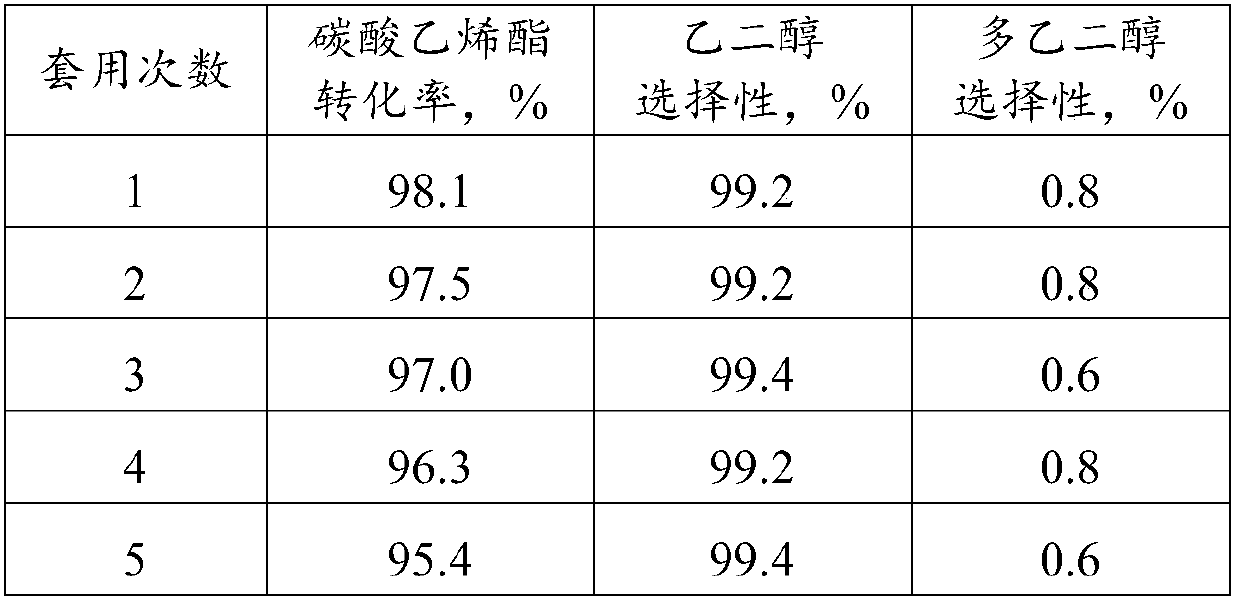

Examples

Embodiment 1

[0017] Preparation of silica-alumina gel SA1: Dissolve 22.1g of aluminum nitrate in 200ml of absolute ethanol at room temperature, stir for 20min, and dissolve it to obtain solution A1; dissolve 58.9g of tetraethyl orthosilicate in 200ml of absolute ethanol, add After stirring 200ml of deionized water and 5ml of concentrated nitric acid for 20 minutes, the prehydrolyzed mixture B1 was obtained; the solution A1 was poured into the mixture B1, and after stirring at room temperature for 1 hour, concentrated ammonia water was added dropwise until the pH value was 8. Then stand and age at 60°C for 12h, filter, wash the precipitate 3 times with absolute ethanol, and put it in an oven at 120°C overnight to obtain silica-alumina gel SA1, which was determined by ICP-AES, Al 2 o 3 The mass percentage content is 14.9%.

Embodiment 2

[0019] Preparation of silica-alumina gel SA2: Dissolve 7.3g of aluminum nitrate in 200ml of anhydrous methanol at room temperature, stir for 20min, and dissolve it to obtain solution A2; dissolve 65.9g of tetraethyl orthosilicate in 200ml of anhydrous methanol, add After stirring 200ml of deionized water and 5ml of concentrated nitric acid for 20 minutes, the prehydrolyzed mixture B2 was obtained; the solution A2 was poured into the mixture B2, and after stirring at room temperature for 1 hour, concentrated ammonia water was added dropwise until the pH value was 8. Then stand and age at 80°C for 20h, filter, wash the precipitate with anhydrous methanol for 3 times, and put it in an oven at 120°C overnight to obtain silica-alumina gel SA2, which was determined by ICP-AES. 2 o 3 The mass percentage content is 5.1%.

Embodiment 3

[0021] Preparation of silica-alumina gel SA3: The preparation steps are the same as in [Example 1], except that the amounts of aluminum nitrate and tetraethyl orthosilicate used are 36.8 g and 52.0 g respectively, to obtain silica-alumina gel SA3, which is measured by ICP-AES, and the Al 2 o 3 The mass percentage content is 24.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com