A method for extraction and separation of ginkgo biloba diterpene lactones

A technology for the separation of ginkgo diterpene lactone and its separation method, which is applied in the direction of organic chemistry, can solve the problems of high content of ginkgo acid, low yield and low purity of ginkgo diterpene lactone, etc., and achieve low content of ginkgo acid, high purity, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

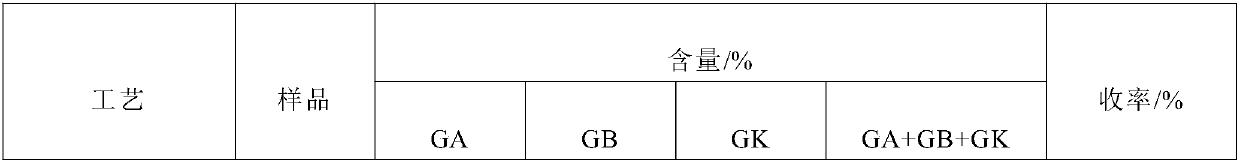

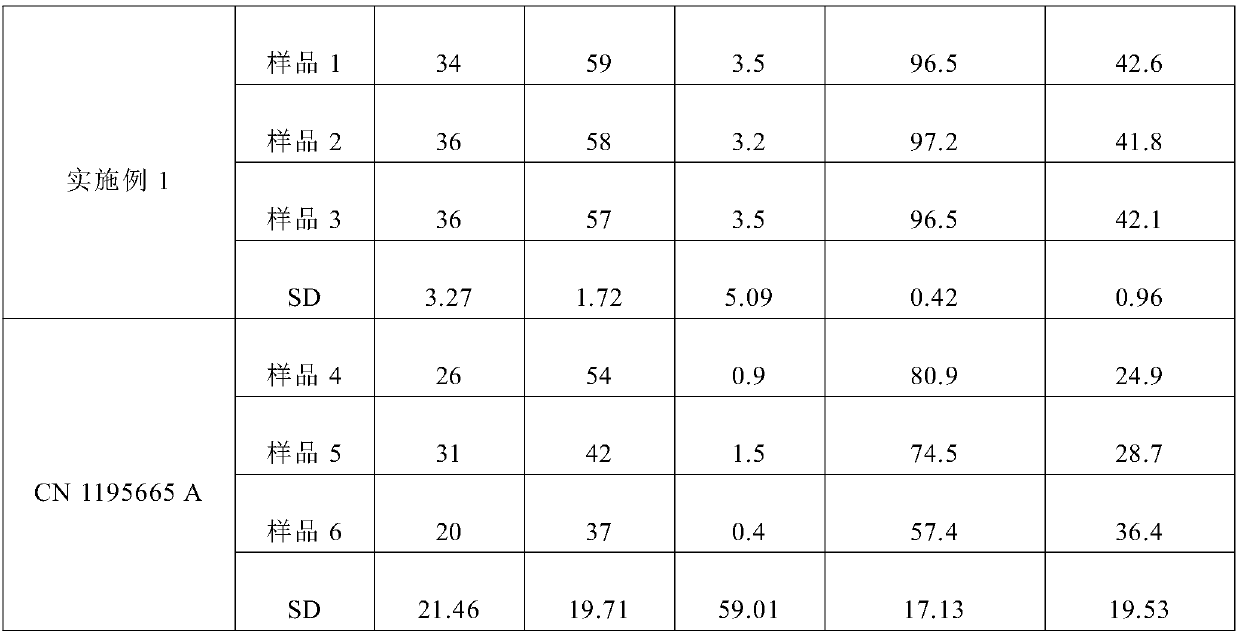

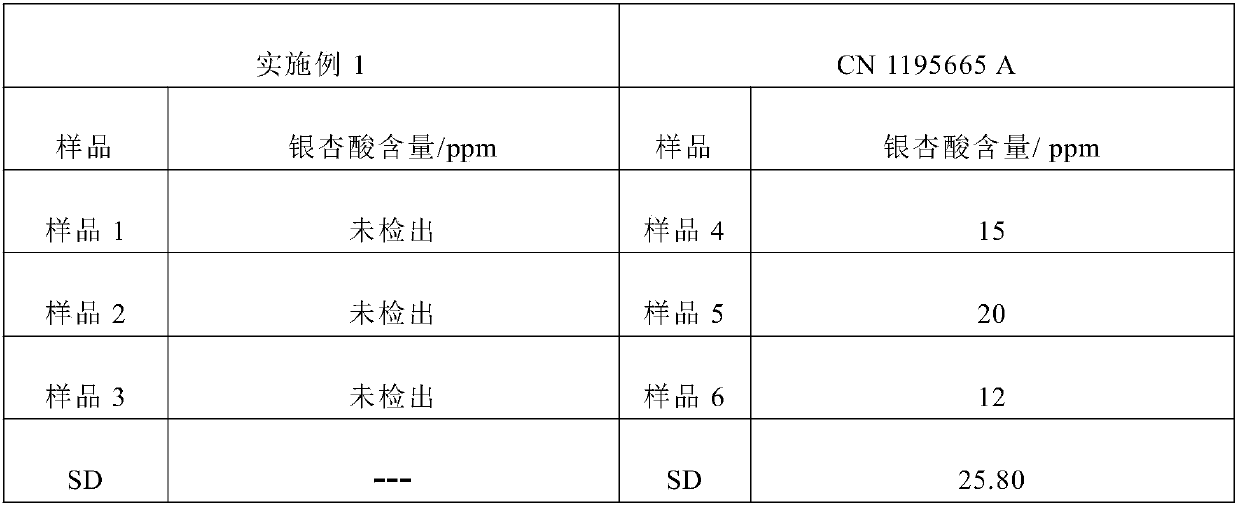

Embodiment 1

[0034] Get Ginkgo biloba (the dried leaf of Ginkgo biloba L. of Ginkgoaceae plant Ginkgo biloba L., purchased in Pizhou, Jiangsu) medical material 50kg, add 14 times the amount of decoction and extract 3 times, each time for 1 hour, combine the extracts, concentrate, filter to obtain Concentrate. Add 10% active carbon by weight of ginkgo biloba to the concentrated solution, stir and adsorb for 24 hours, let stand overnight, discard the supernatant, and collect the adsorbent. Add 20L methanol to the adsorbent, heat to boil for 1 hour, let cool, take the supernatant, add 20L methanol to the extracted adsorbent and repeat the extraction twice, combine the above three extracts, concentrate under reduced pressure to obtain concentrated Liquid (relative density 1.35) was refrigerated for 3 days. Centrifuge the refrigerated concentrated solution, collect the precipitate, add water to the precipitate and wash 3 times, discard the water, add 5 times the amount of methanol to the preci...

Embodiment 2

[0037] Get Ginkgo biloba (the dry leaf of Ginkgo biloba L. of Ginkgoaceae plant Ginkgo biloba L., purchased in Pizhou, Jiangsu) medical material 50kg, add 8 times the amount of 10% ethanol and heat and reflux to extract 2 times, each time for 1.5 hours, combine the extracts, concentrate, filter , to obtain a concentrated solution. Add 15% polyamide by weight of ginkgo biloba to the concentrated liquid, stir and adsorb for 36 hours, let stand overnight, discard the supernatant, and collect the adsorbent. Add 30L 95% ethanol to the adsorbent, heat to boiling for 1.5 hours, let cool, take the supernatant, add 30L ethanol to the extracted adsorbent and repeat the extraction 3 times, combine the above 4 extracts, concentrate under reduced pressure, The concentrated solution (d=1.40) was refrigerated for 5 days. Centrifuge the refrigerated concentrate, collect the precipitate, add water to the precipitate and wash 3 times, discard the water, add 2 times the amount of ethanol to the...

Embodiment 3

[0040] Get Ginkgo biloba (the dry leaf of Ginkgo biloba L. of Ginkgoaceae plant Ginkgo biloba L., purchased in Pizhou, Jiangsu) medical material 50kg, add 5 times the amount of 20% ethanol and heat and reflux to extract 4 times, each time for 3 hours, combine the extracts, concentrate, filter , to obtain a concentrated solution. Add silica gel with 20% weight of ginkgo biloba medicinal materials to the concentrated solution, stir and adsorb for 48 hours, let stand overnight, discard the supernatant, and collect the adsorbent. Add 20L 40% acetone to the adsorbent, heat it to boiling for 1.5 hours, let it cool, take the supernatant, add 20L 40% acetone to the extracted adsorbent and repeat the extraction twice, combine the above three extracts, and depressurize Concentrate to obtain a concentrated solution (d=1.38) and refrigerate for 3 days. Take the refrigerated concentrated solution and centrifuge to collect the precipitate, add water to the precipitate and wash 3 times, dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com