Manufacture method of UV-resistant (ultraviolet-resistant) dye and corresponding coating-type dye polarizer

A production method and technology for polarizers, which are applied in the preparation of azo dyes, azo dyes, organic dyes, etc., can solve the problems affecting the reliability and service life of dye polarizers, fading, and easy photodegradation. Effects of photodegradation and fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The description of the following embodiments refers to the attached drawings to illustrate specific embodiments that the present invention can be implemented. The directional terms mentioned in the present invention, such as "up", "down", "front", "rear", "left", "right", "inner", "outer", "side", etc., are for reference only The direction of the additional schema. Therefore, the directional terms used are used to describe and understand the present invention, rather than to limit the present invention.

[0043] In the figures, units with similar structures are indicated by the same reference numerals.

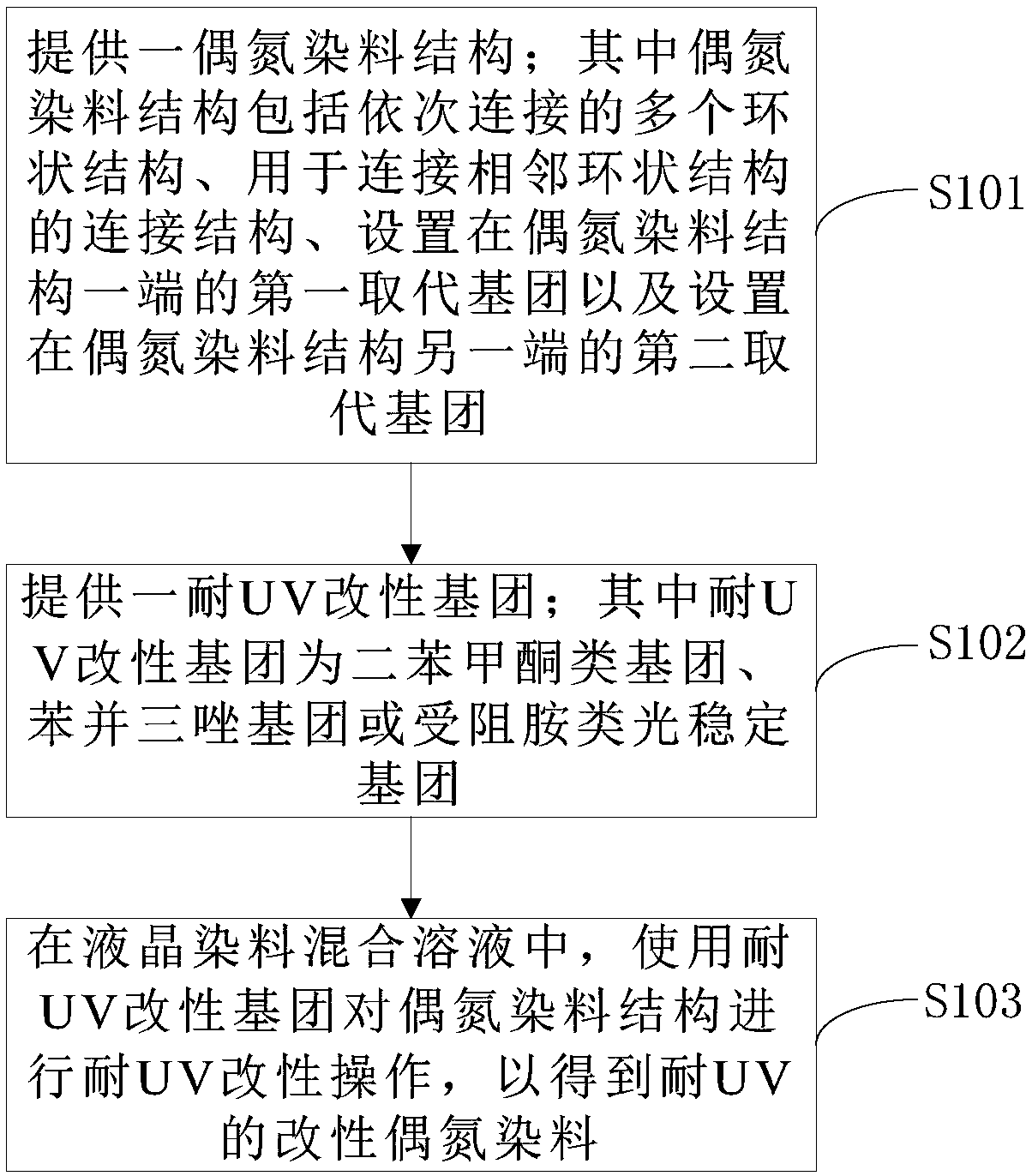

[0044] Please refer to figure 1 , figure 1 It is a flowchart of a preferred embodiment of the method for producing UV-resistant dyes of the present invention. The manufacturing method of the UV-resistant dye of the preferred embodiment includes:

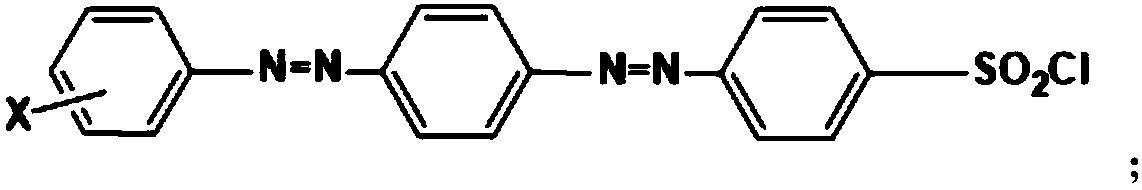

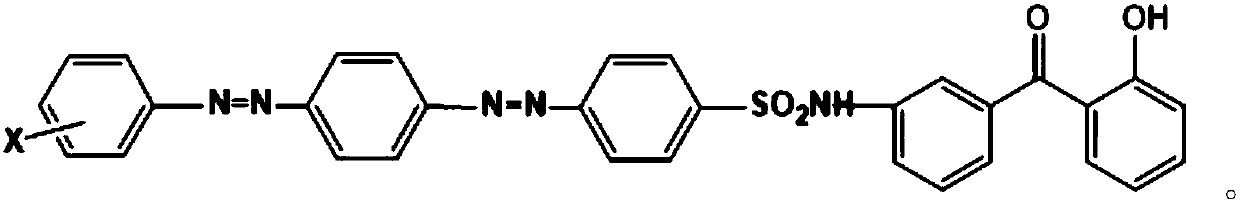

[0045] Step S101, providing an azo dye structure; wherein the azo dye structure includes a plurality of cyclic structures conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com