Steel slag dry processing and waste heat recovery and power generation method

A technology of waste heat recovery and dry treatment, which is applied in the direction of recycling technology, machines/engines, steam engine devices, etc., can solve the problems of plant structure production equipment corrosion, environmental pollution in the working area, clogged water treatment system, etc., to achieve the elimination of groundwater quality Pollution problems, overcoming long cycle times, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

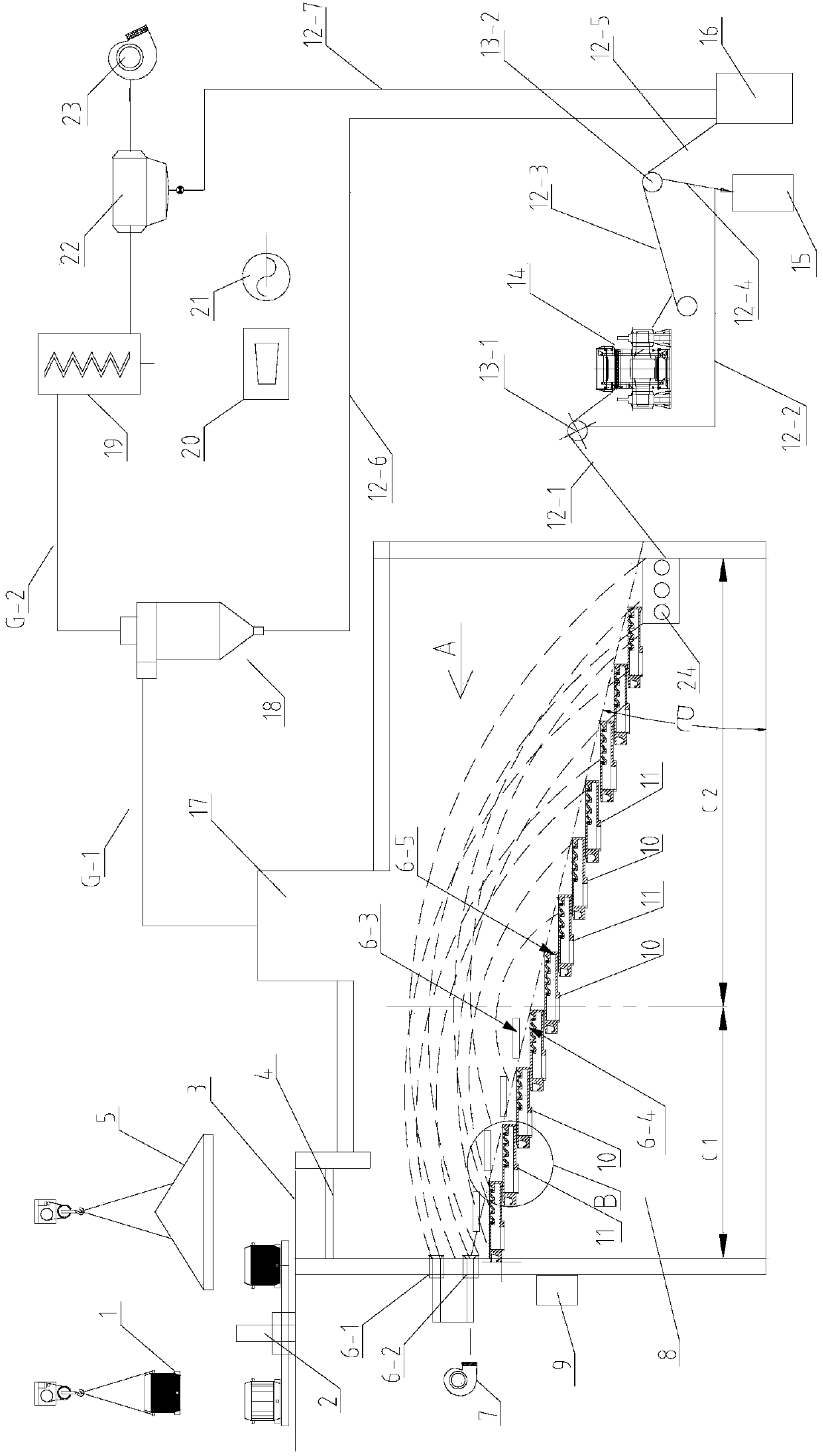

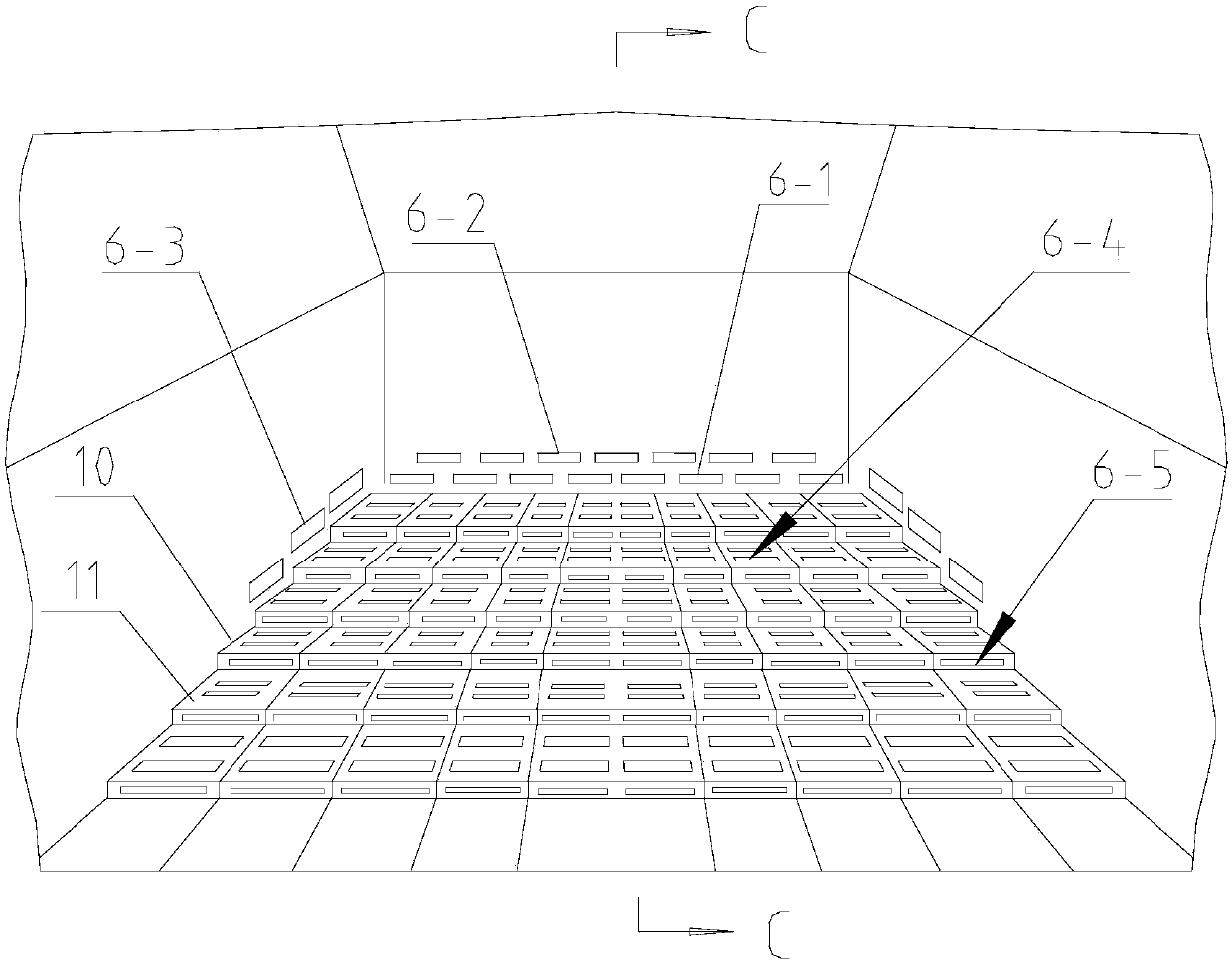

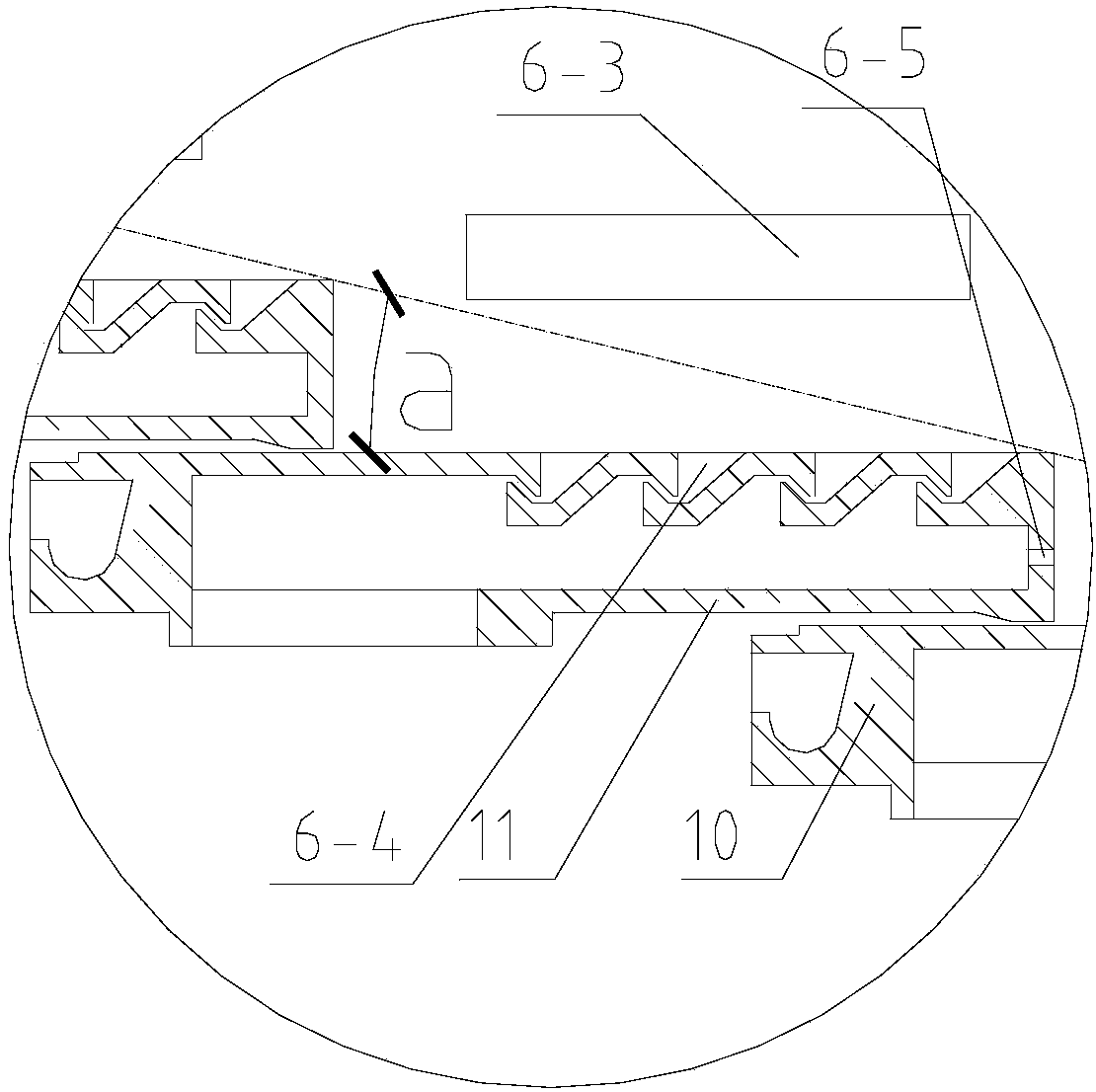

[0018]The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings: a method for dry processing of steel slag and waste heat recovery and power generation, which is provided with a closed walk-in cooler 8, and the steel slag inlet 3 of the closed walk-in cooler 8 A high-temperature isolation screen 4 is arranged directly above, and the turning table 2 is fixed on one side of the steel slag inlet 3 . The top of the high-temperature isolation screen 4 is provided with a movable dust collection cover 5, and the steel slag tank 1 is located above the turning table 2. The top of the middle part of the airtight walk-in cooler 8 is provided with a hot-blast air intake 17, and the pipe i-G-1 connects the top of the hot-blast air intake 17 with the upper air inlet of the cyclone dust collector 18. Air knife i-6-1 and air knife ii-6-2 are arranged above the outer side of the front end of the airtight step cooler 8, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com