Carbon fiber material and preparation method and application thereof and method of preparing pantograph slide block

A carbon fiber material and fiber material technology, applied in the field of material science, can solve problems such as low efficiency, long time consumption, and complex preparation process of composite materials, and achieve the effect of simple process, low price, easy procurement and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

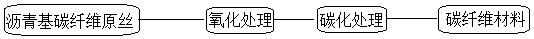

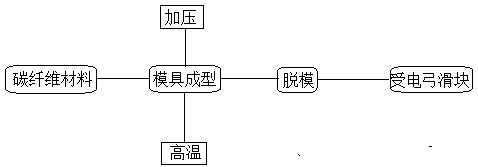

[0024] The following will be attached Figure 1~2 Examples further describe the present invention.

[0025] according to figure 1 The preparation process of carbon fiber materials is carried out, and pitch-based carbon fiber precursors are used as raw materials. The price of pitch-based carbon fiber precursors is low, the carbon content is high, and the preparation process is simple, easy to purchase and store, and the pitch-based carbon fiber precursors The silk contains oil, the friction coefficient is small, the electrical conductivity is good, and it also has the advantages of oxidation resistance, high temperature resistance, acid and alkali resistance, etc., so that the prepared carbon fiber material has good performance in electrical conductivity and wear resistance, and is very suitable for the role of affected people. Prepare raw materials for electrolytic slides.

[0026] Oxidize and carbonize the purchased pitch-based carbon fiber precursors to obtain carbon fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com