Embossing roller die manufactured by using steel strip

An embossing roll and steel belt technology, applied in the field of embossing roll mould, can solve the problems of large amount of mold steel for embossing roll mold, difficult preparation and heat treatment process, and high cost of raw materials, so as to achieve large amount of mold steel and avoid heat treatment deformation. , the effect of high raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

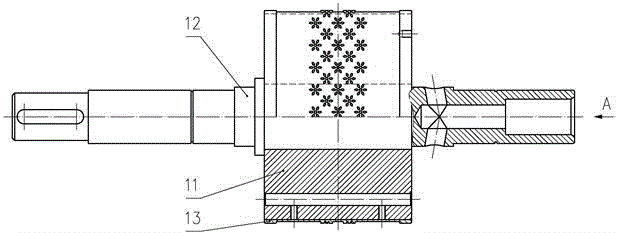

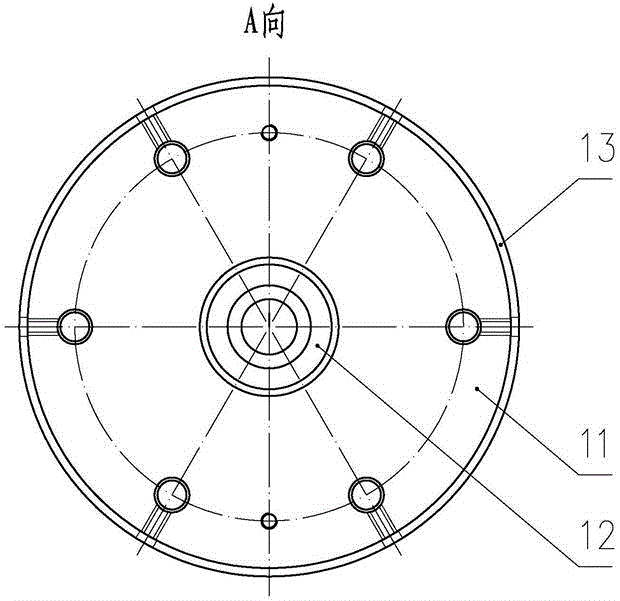

[0019] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following is a detailed description in conjunction with the embodiments and accompanying drawings.

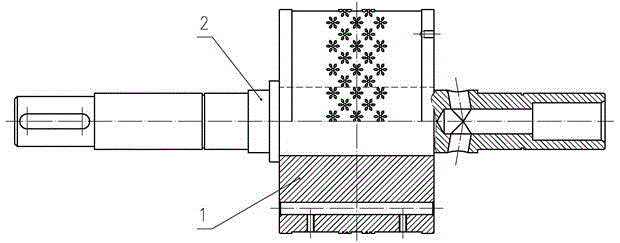

[0020] See figure 1 , 2 3. This embodiment provides an embossing roller die made of steel belt, which includes a pattern layer 11, a base 12 and a mandrel 13. The pattern layer 11 is made of steel strip with a hardness ≥ 58HRC and no heat treatment is required. The pattern layer 11 is fixed on the base body 12 by welding, and then a pattern is processed on the pattern layer. The base 12 and the mandrel 13 are made of carbon steel, and the base 12 is sleeved on the mandrel 13 with interference fit.

[0021] In the present invention, the pattern layer 11 can also be fixed on the base 12 by means of magnetic coupling or the like. Of course, other feasible fixing methods can also be adopted.

[0022] Different from the embossing roller die in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com