Method for profiling spherical involute spiral bevel gear

A spherical involute, spiral bevel gear technology, applied in the direction of toothed components, belt/chain/gear, hoisting device, etc., can solve the problems of limited processing principle, poor gear interchangeability, principle error and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

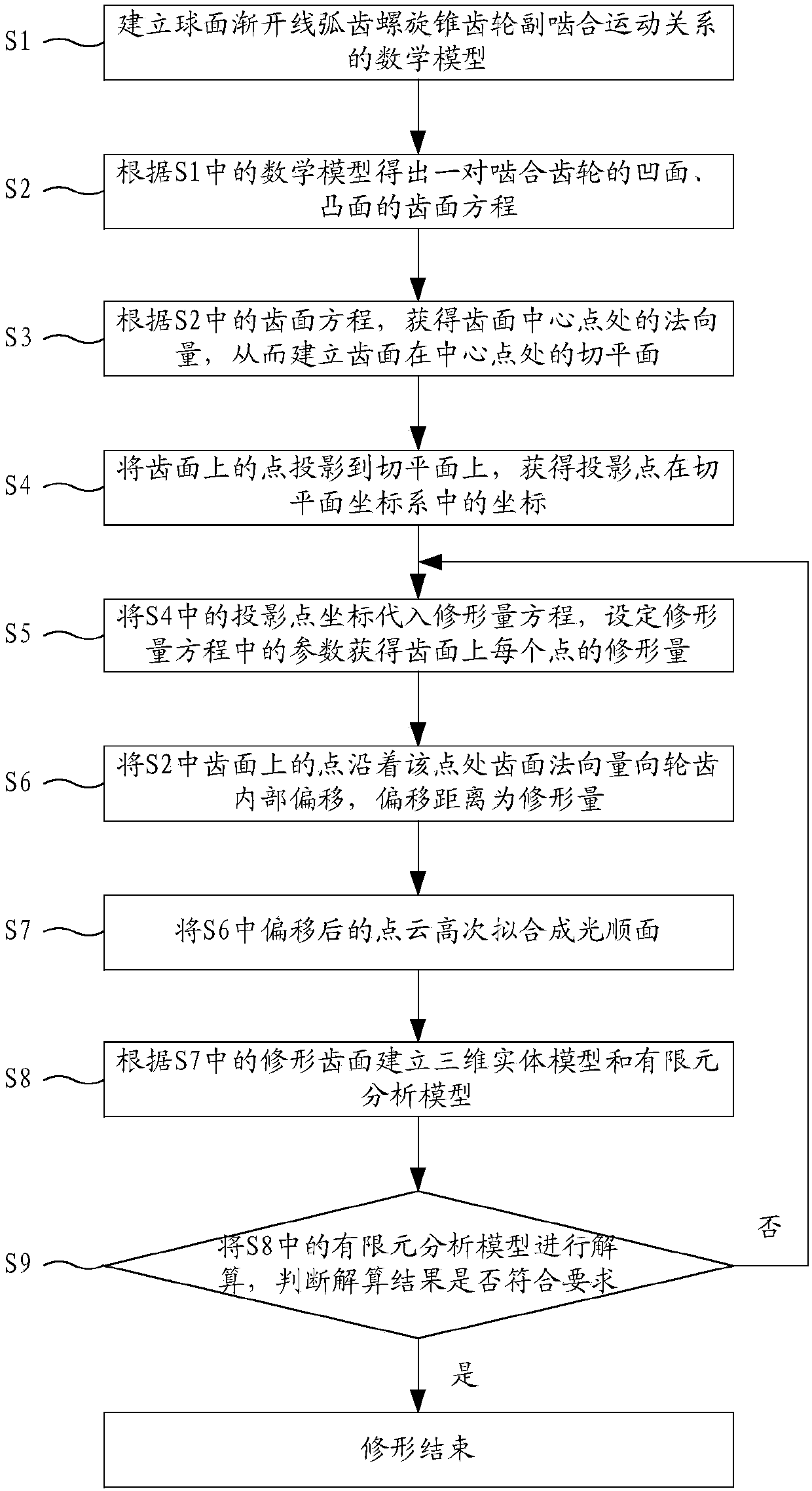

[0081] Such as figure 1 Shown, the present invention comprises the following steps:

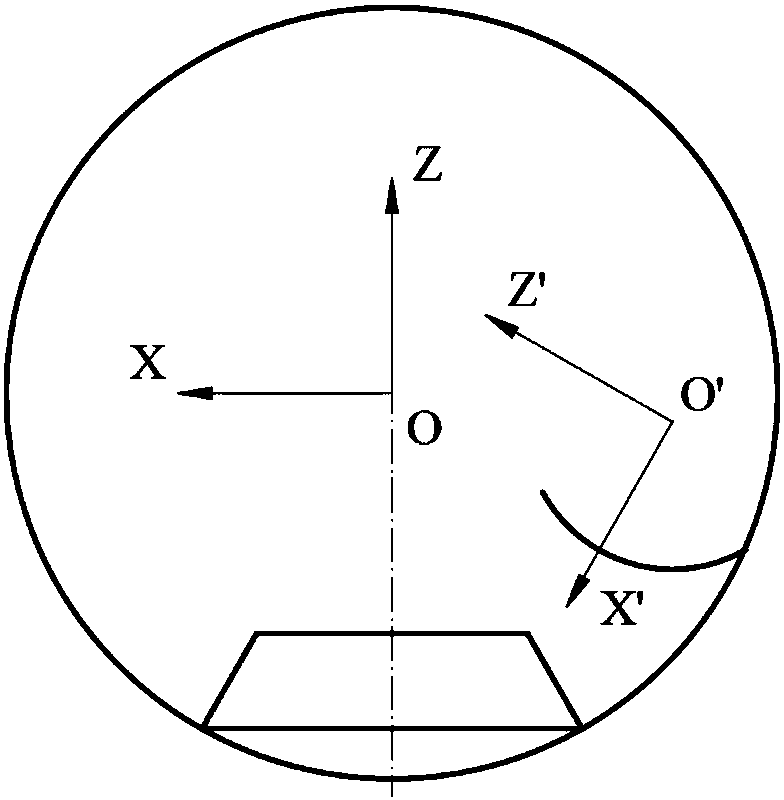

[0082] S1, such as figure 1 As shown, according to the principle of spherical involute generation, the meshing motion relationship of the spiral bevel gear pair is obtained, and the corresponding three-dimensional mathematical model is established.

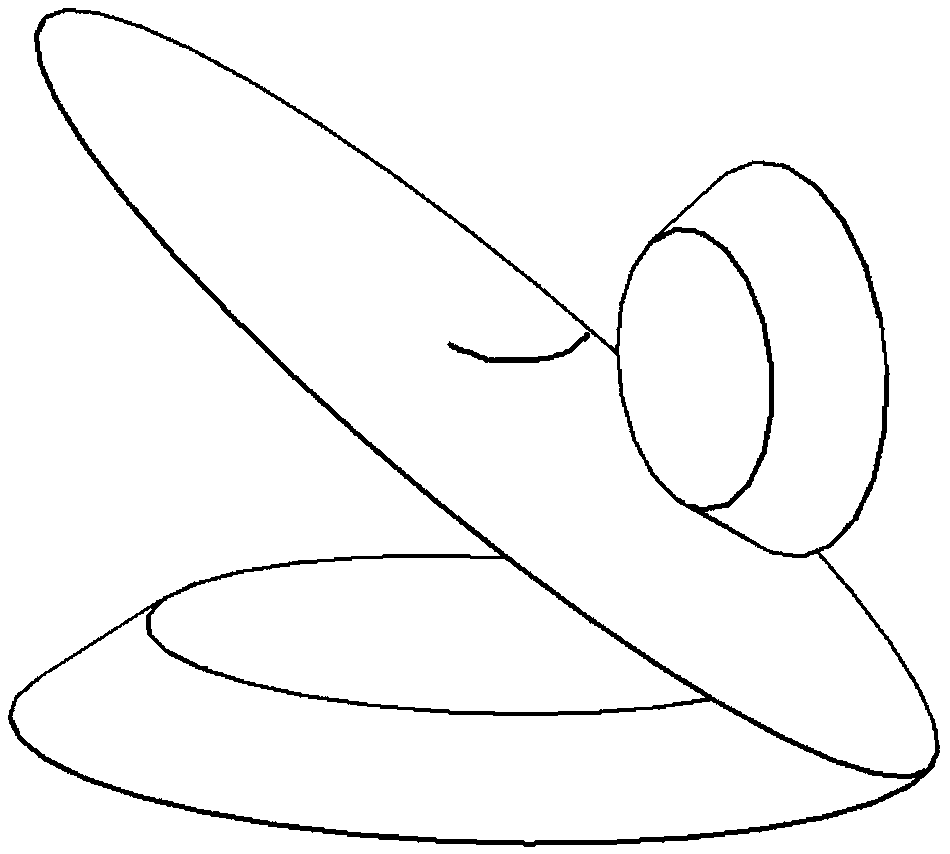

[0083] The center of a circular plane coincides with the vertex of the base cone of the gear and is tangent to the base cone of the gear. When the circular plane rolls around the base cone in pure rolling, the trajectory of any point on the circular plane is the spherical involute. When a pair of spiral bevel gears are in meshing motion, the circular arc line on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com