High color rendering index laser white light device and implementation method thereof

A high color rendering, laser technology, applied in the field of lighting, can solve the problems of the laser white light device being difficult to achieve high color rendering index, limited use, etc., and achieve the effect of simple and convenient implementation method, low cost, and high excitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

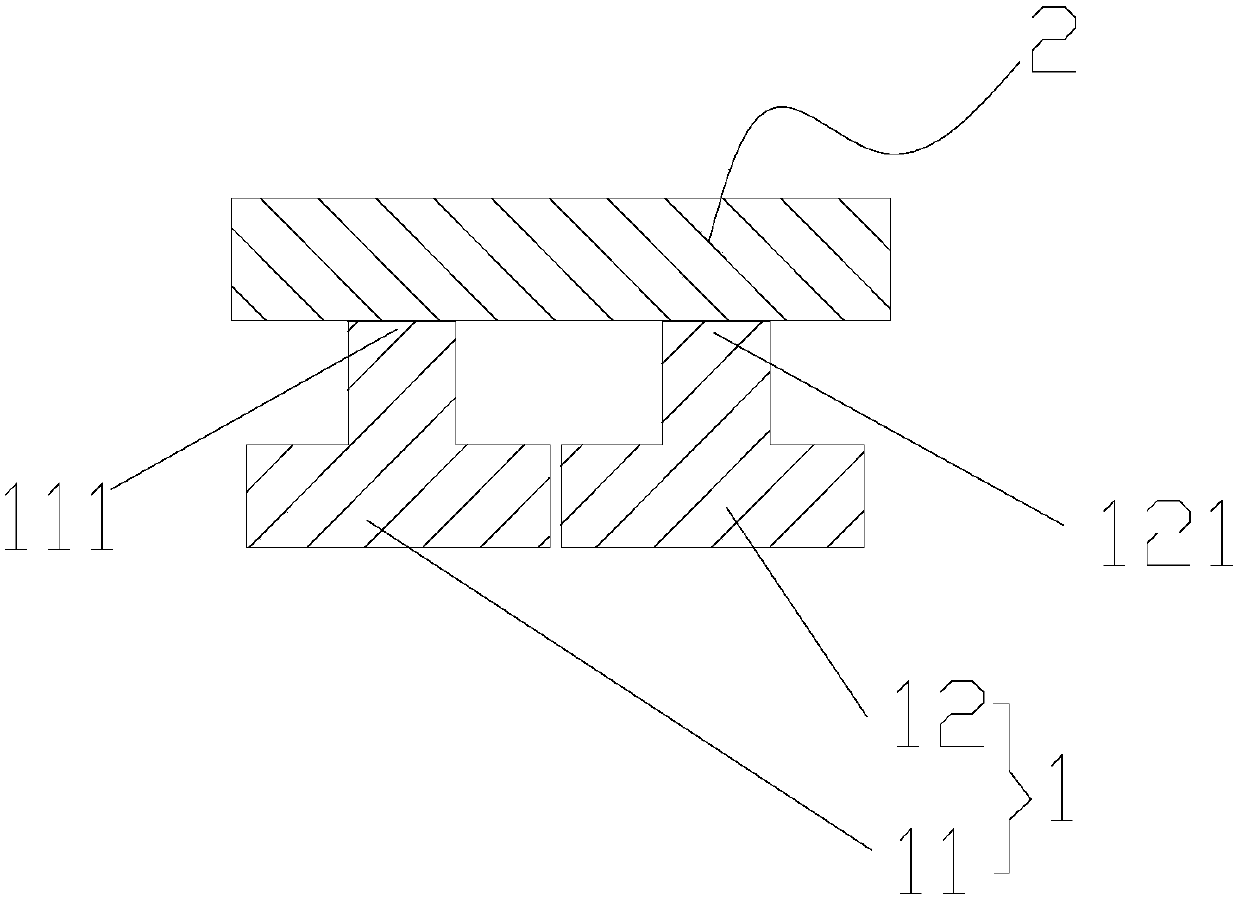

[0043] Such as figure 1 As shown, a high color rendering index laser white light device according to the present invention includes a light source emitting device 1 and a light conversion medium 2, the light conversion medium 2 is fixed on the surface of the light source exit end of the light source emitting device 1, and the light source emits The device 1 includes a blue laser emitting device 11 and a red light source emitting device 12 . The light source emitted by the red light source emitting device 12 is a laser light source or an LED light source. The output wavelength of the light source emitted by the red light source emitting device 12 is 620-750nm. The output wavelength of the blue laser emitted by the blue laser emitting device 11 is 420-470nm. The emission wavelength range of the light conversion medium 2 is 520-620nm, and the transmittance of visible light is ≥85%. The light conversion medium 2 is yellow glass, yellow ceramic or yellow single crystal material....

Embodiment 2

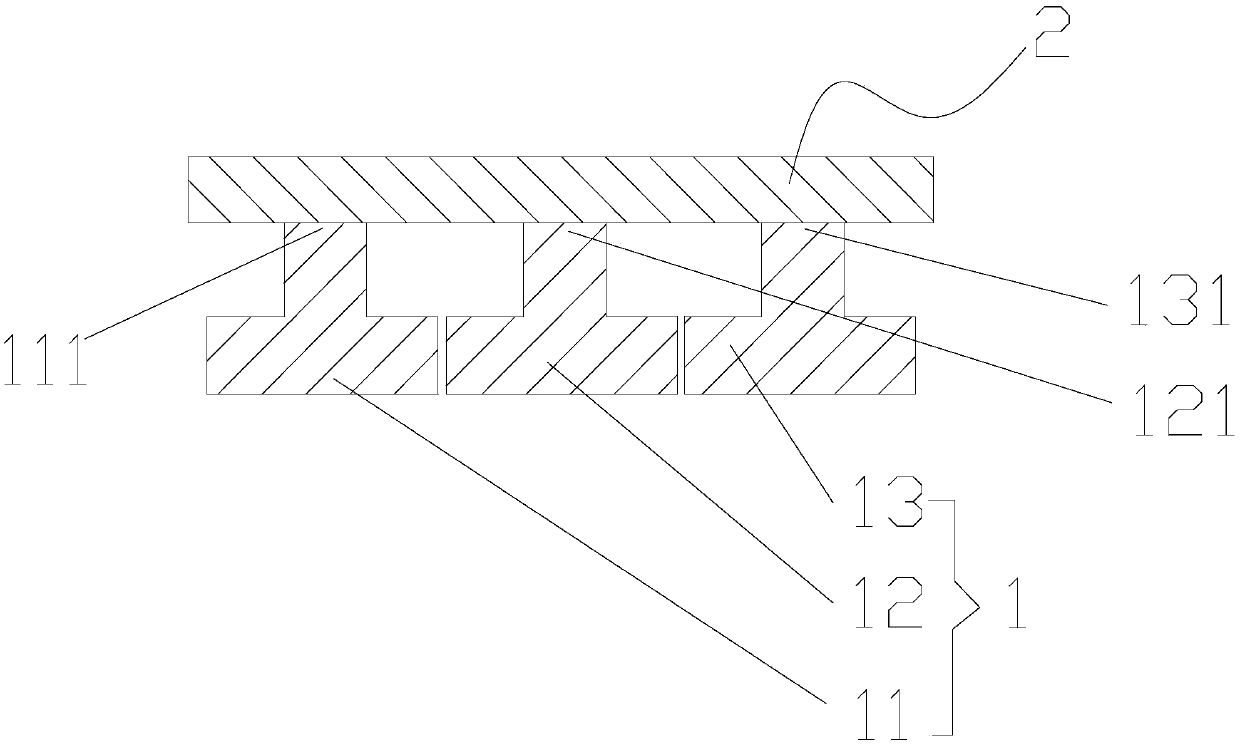

[0046] Such as figure 2 As shown, the difference between this embodiment and embodiment 1 is:

[0047] The blue laser emitting device 11 and the red light source emitting device 12 can be turned on or off at the same time.

[0048] The light source emitting device 1 further includes a green light source emitting device 13 . The output wavelength of the light source emitted by the green light source emitting device 13 is 495-570 nm. The blue laser emitting device, the red light source emitting device and the green light source emitting device can be turned on or off simultaneously.

[0049] The implementation method of the high color rendering index laser white light device is that the blue laser emitting device 11, the red light source emitting device 12 and the green light source emitting device 13 are simultaneously connected by their respective light source outlet a111, light source outlet b121 and The light source output end c131 emits blue laser light, red light sourc...

Embodiment 3

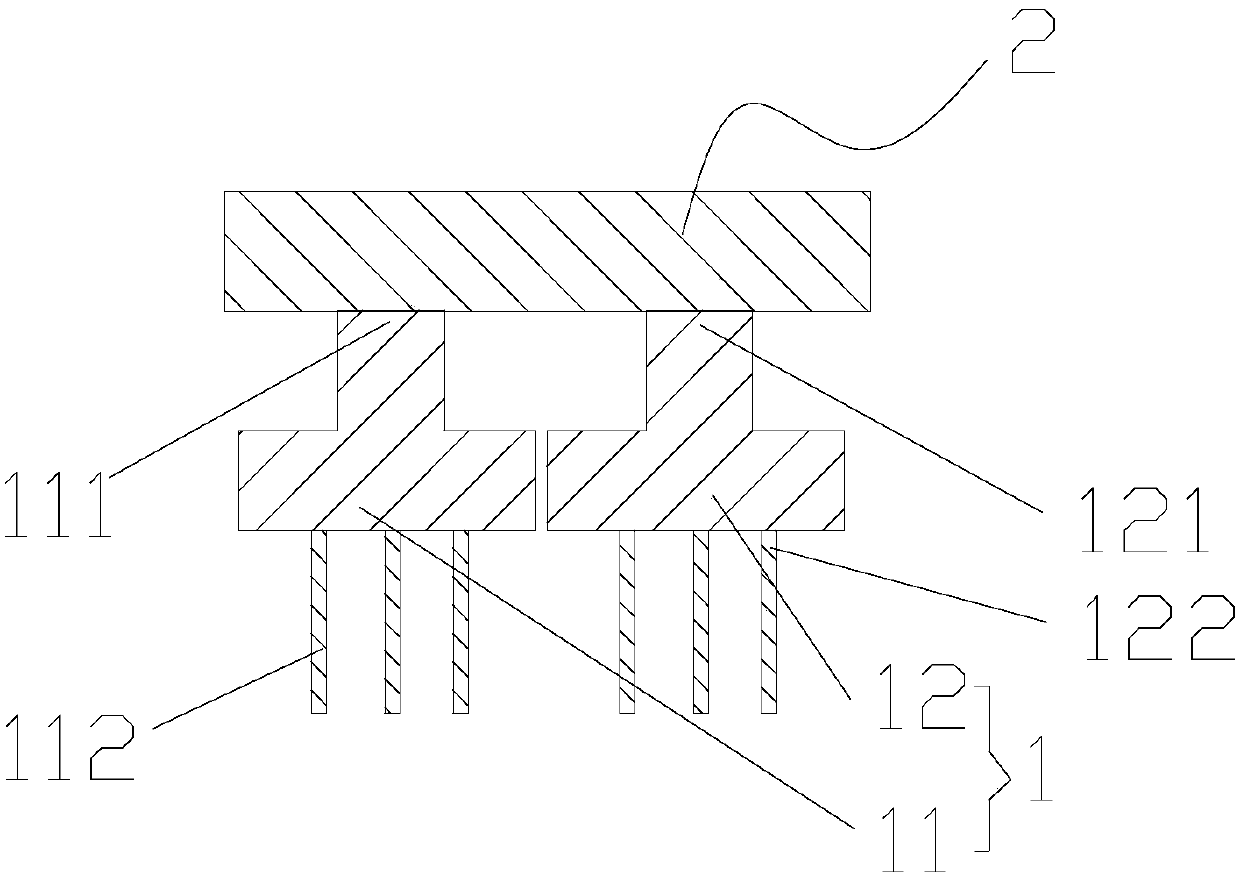

[0051] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the blue-ray laser emitting device 11 is an in-line blue-ray laser emitting device, and the light source output end a111 is located on the upper surface of the in-line blue-ray laser emitting device. The lower surface of the blue laser emitting device is provided with a pin a112. The red light source emitting device 12 is an in-line red light source emitting device, the light source output end b121 is located on the upper surface of the in-line red light source emitting device, and the lower surface of the in-line red light source emitting device is provided with pins b122.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com