Method and device for transferring decorative segment of embossing film

A technology of embossed film and segments, which is applied in the fields of crafts, decorative arts, and rotary printing machines for producing decorative surface effects, and can solve problems such as interference in the processing of embossed films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

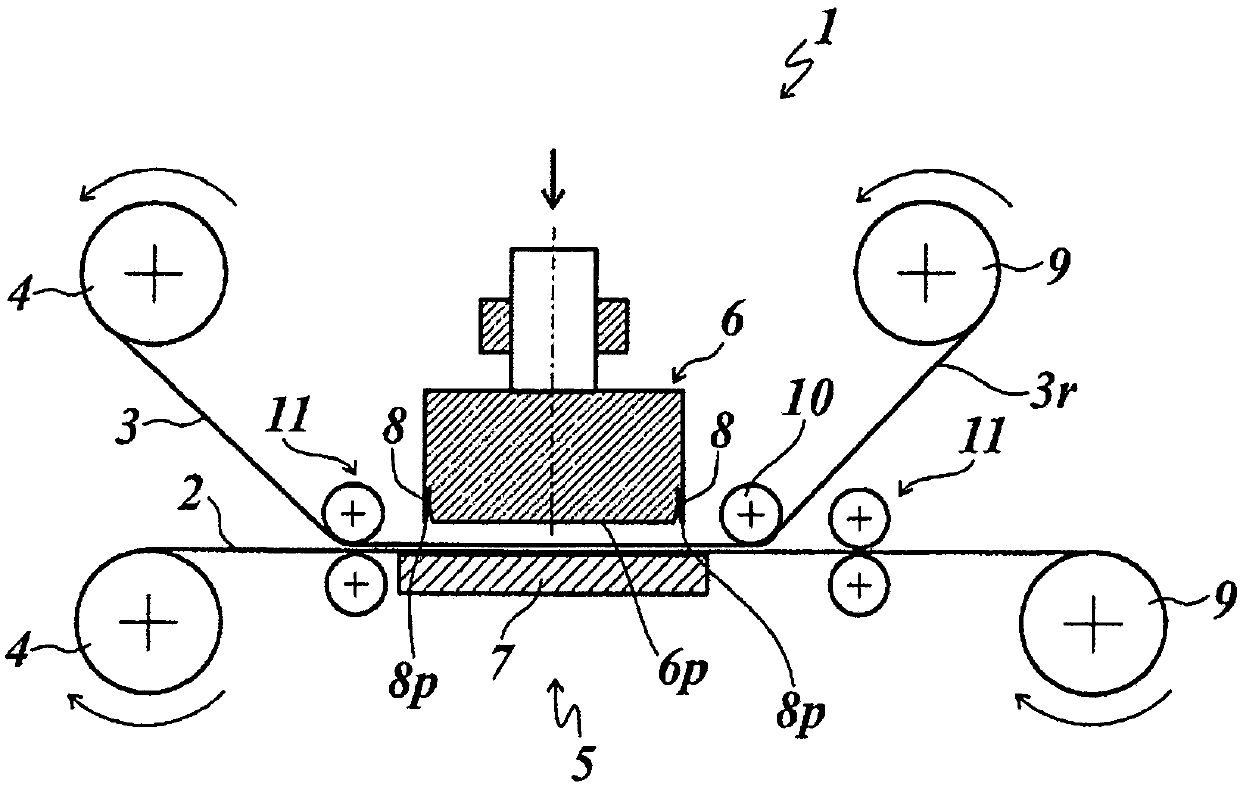

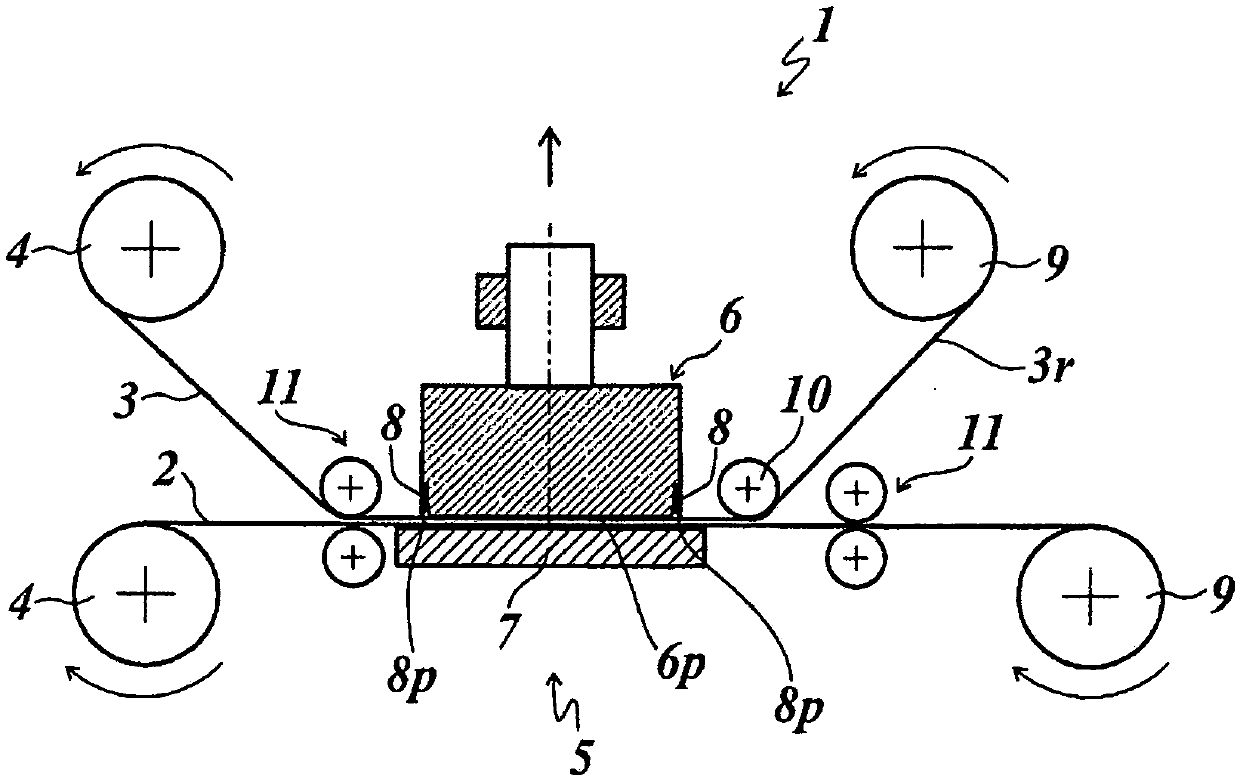

[0058] figure 1 and 2 A first exemplary embodiment of an embossing device 1 according to the invention is shown schematically.

[0059] In the illustrated embodiment, the embossing device 1 is configured as a lifting embossing device and is used for a roll-to-roll method, in which the substrate 2 to be embossed and the embossing film 3 are supplied on a storage roll 4 .

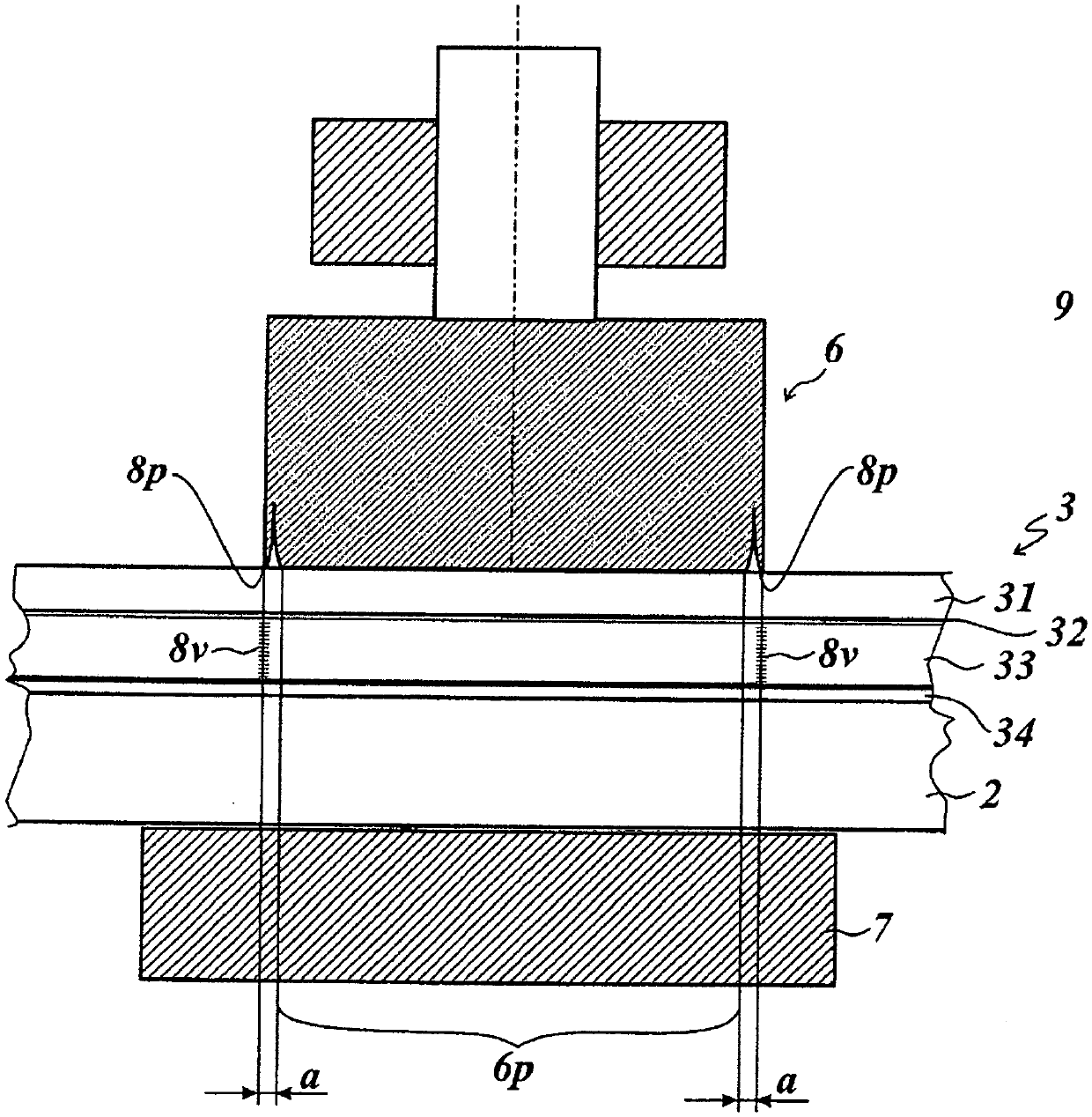

[0060] The embossed film 3 comprises a carrier film 31, a release layer 32, a transfer layer 33 and an adhesive layer 34 (see image 3 ). under the Figure 9 The structure of the embossed film 3 is described in more detail in .

[0061] The embossing film 3 and the substrate 2 are fed to an embossing station 5 with a vertically movable embossing mold 6 , wherein the underside of the substrate 2 rests on an embossing support 7 in the embossing station 5 . The embossing film 3 is situated with its adhesive layer on the upper side of the substrate 2 . Alternatively (not shown), the stamping die can also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com