Long-sized polarizing plate with optical compensation layer and organic el panel using the same

An optical compensation layer, strip-shaped technology, applied in the direction of optics, optical elements, polarizing elements, etc., can solve the problems of difficulty in controlling the slow axis, deviation of the optical axis from the set direction, and uneven characteristics in the width direction, achieving Excellent reflective hue and viewing angle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] (Production of polycarbonate resin film)

[0107] Polymerization was performed using a batch polymerization apparatus including two vertical reactors equipped with stirring blades and a reflux cooler controlled at 100°C. 9,9-[4-(2-hydroxyethoxy)phenyl]fluorene (BHEPF), isosorbide (ISB), diethylene glycol (DEG), diphenyl carbonate (DPC) and magnesium acetate The hydrate becomes BHEPF / ISB / DEG / DPC / magnesium acetate=0.348 / 0.490 / 0.162 / 1.005 / 1.00×10 according to the molar ratio -5 way of investing. After the inside of the reactor was sufficiently replaced with nitrogen (oxygen concentration: 0.0005 to 0.001% by volume), it was heated with a heat medium, and stirring was started when the internal temperature reached 100°C. 40 minutes after the start of the temperature rise, the internal temperature was controlled to be 220° C. to maintain the temperature, and at the same time the pressure was reduced, and it was set to 13.3 kPa over 90 minutes after reaching 220° C. Introdu...

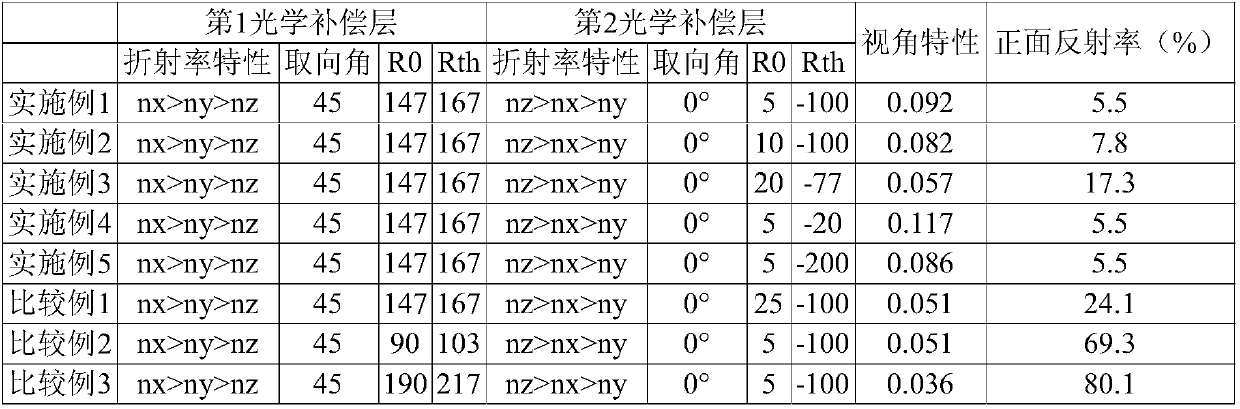

Embodiment 2~5 and comparative example 1~3

[0133] A polarizing plate with an optical compensation layer and an organic EL panel were produced with the configuration shown in Table 1. The obtained polarizing plate and organic EL panel with an optical compensation layer were subjected to the same evaluation as in Example 1. As shown in Table 1, the organic EL panels of Examples 2 to 5 had good viewing angle characteristics and front reflectance. Furthermore, regarding these organic EL panels, it was confirmed that a neutral reflection hue was realized in any of the frontal direction and the oblique direction. On the other hand, the organic EL panels of Comparative Examples 1 to 3 had insufficient front reflectance and insufficient antireflection characteristics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reduced viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com