Crop straw pretreatment method and application thereof in preparation of ammoniated forage

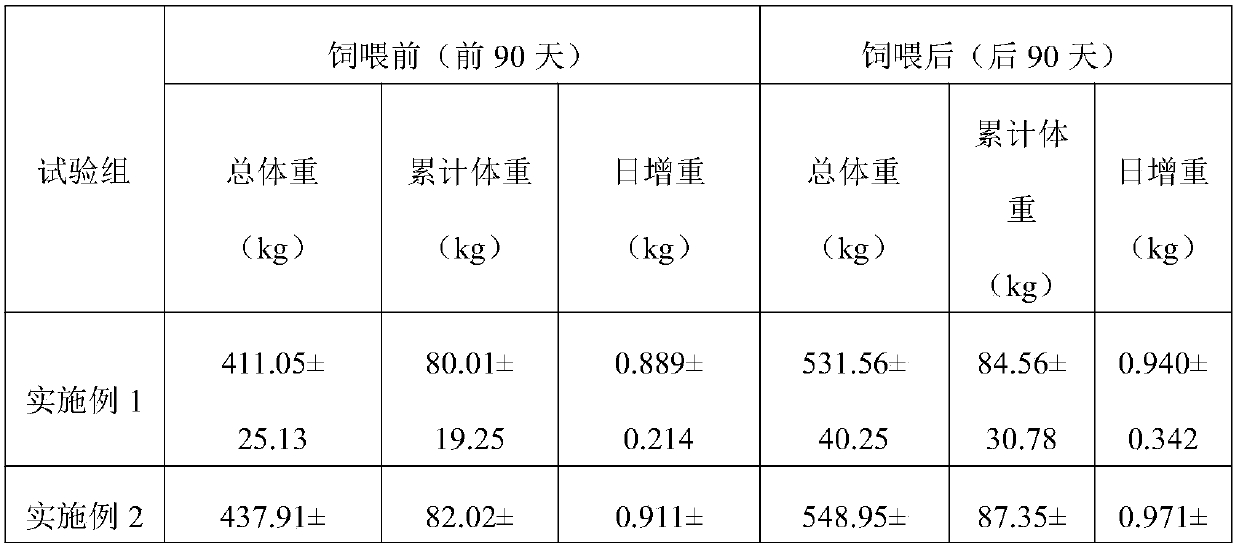

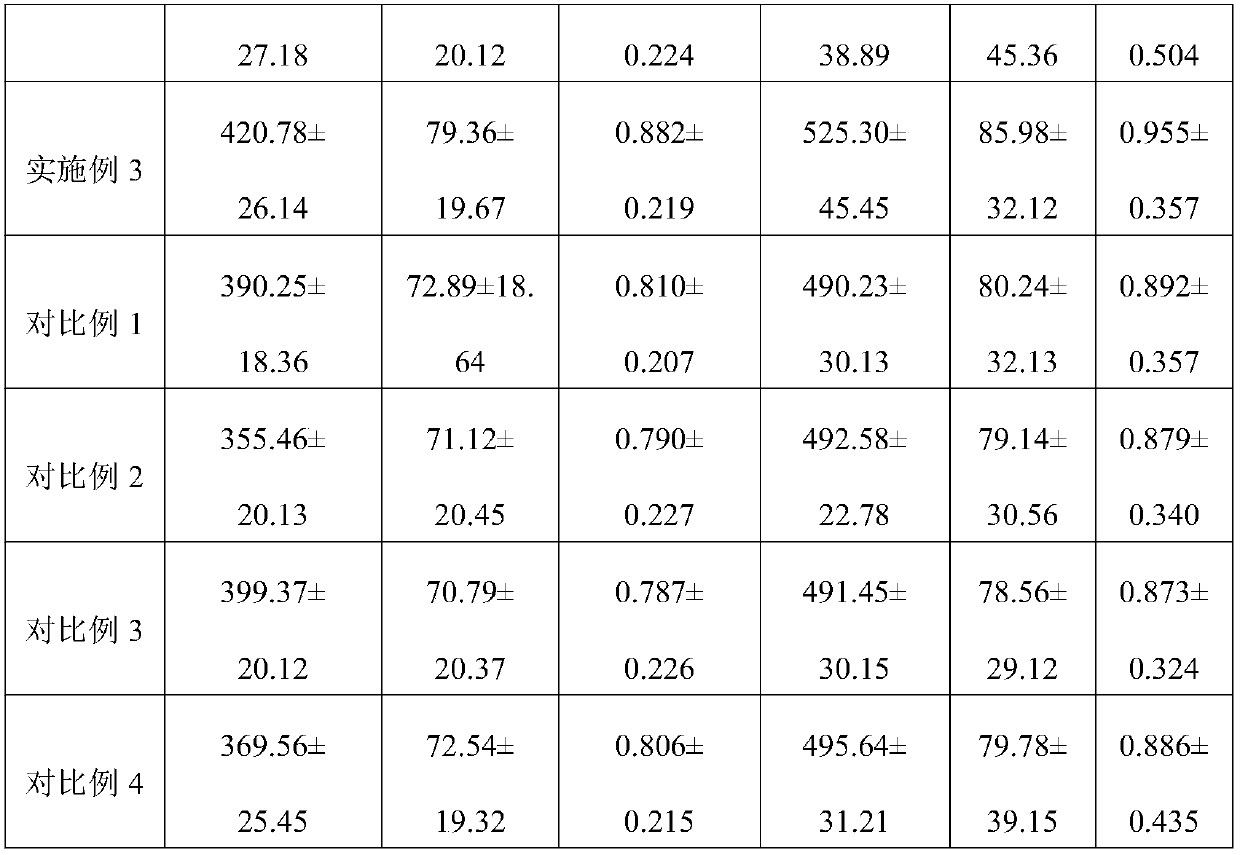

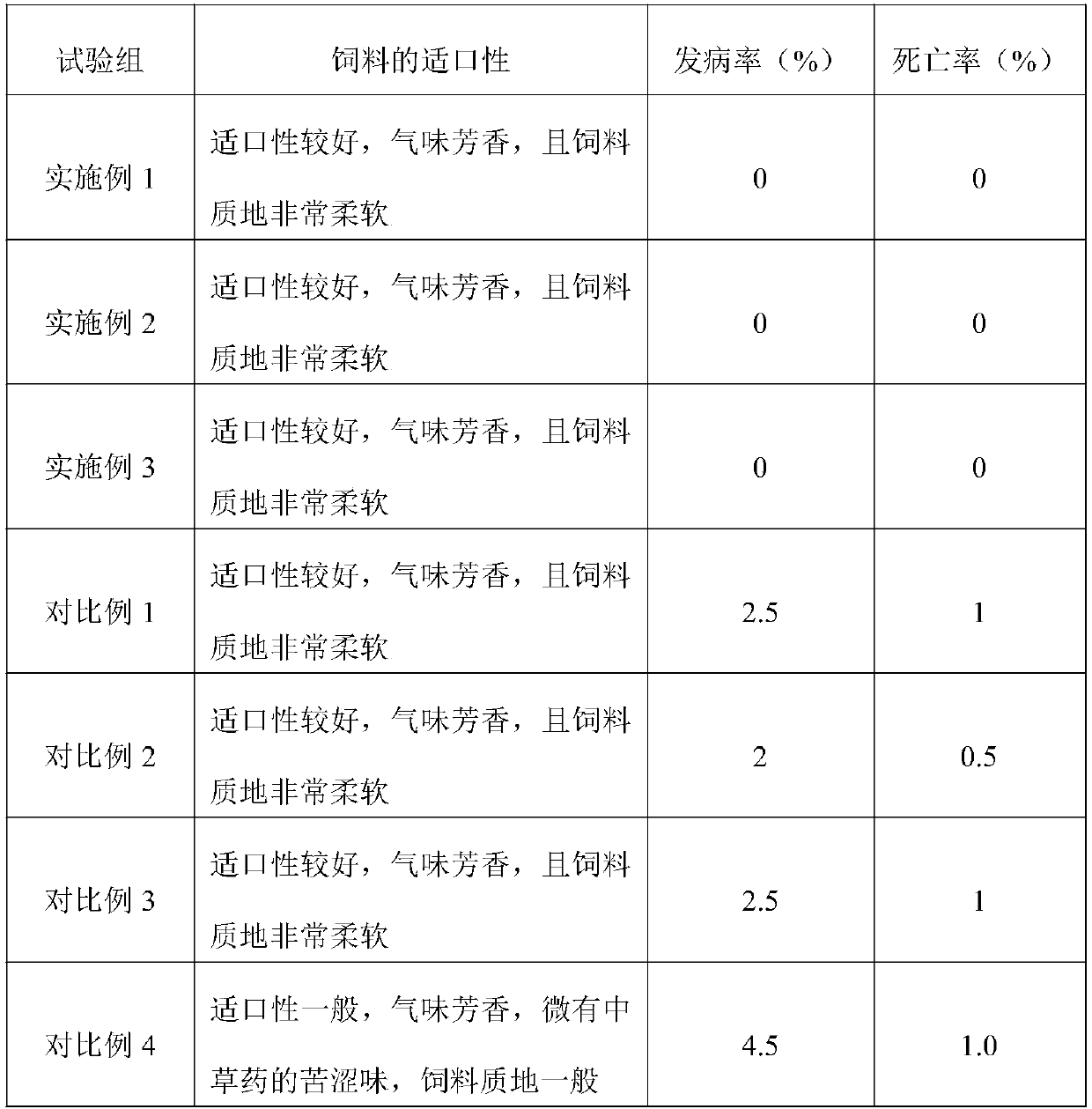

A technology of crop straw and pretreatment, applied in animal feed, animal feed, application and other directions, can solve the problems of poor palatability of feed, low utilization rate of active ingredients of Chinese herbal medicine, low disease resistance of cattle, etc., to increase food intake and improve bacterial resistance morbidity, morbidity and mortality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Applying the crop stalk pretreatment method of the present invention to the preparation process of ammoniated feed, the preparation method of the ammoniated roughage includes the following steps:

[0040] S1: Raw material pretreatment:

[0041] S11: Pretreatment of crop stalks: (1) Softening treatment: dry the tail leaves of sugarcane and corn stalks until the water content is 80%, then mix them, put them into a surfactant, and heat them in an environment with a temperature of 30°C and a pressure of 2.5MPa. Soak in the environment for 1d;

[0042]The surfactant is in parts by weight, comprising the following raw materials: 1.5 parts of D-mannitol, 0.5 part of tripotassium phosphate, 1 part of ethylene glycol, 0.6 part of oleic acid; Potassium, ethylene glycol, and oleic acid were mixed evenly, and subjected to ultrasonic treatment for 10 minutes at a temperature of 28°C and a power of 35W to prepare a surfactant;

[0043] The material ratio of described sugarcane tail...

Embodiment 2

[0059] Applying the crop stalk pretreatment method of the present invention to the preparation process of ammoniated feed, the preparation method of the ammoniated roughage includes the following steps:

[0060] S1: Raw material pretreatment:

[0061] S11: Crop stalk pretreatment: (1) softening treatment: dry sugarcane tail leaves and corn stalks to a water content of 85%, then mix them, put them into a surfactant, and heat them under a temperature of 38°C and a pressure of 3.5MPa. Immerse in the environment for 2d;

[0062] Described surfactant comprises: 2.5 parts of D-mannitol, 1 part of tripotassium phosphate, 2 parts of ethylene glycol, 0.7 part of oleic acid; By D-mannitol, tripotassium phosphate, ethylene glycol, oleic acid Mix evenly, and perform ultrasonic treatment for 13 minutes at a temperature of 28°C and a power of 40W to prepare a surfactant;

[0063] The material ratio of described sugarcane tail leaf and corn stalk after both mixing with surfactant is 2:1; ...

Embodiment 3

[0079] Applying the crop stalk pretreatment method of the present invention to the preparation process of ammoniated feed, the preparation method of the ammoniated roughage includes the following steps:

[0080] S1: Raw material pretreatment:

[0081] S11: Pretreatment of crop stalks: (1) Softening treatment: dry the tail leaves of sugarcane and corn stalks until the water content is 90%, then mix them, put them into a surfactant, and put them in an environment with a temperature of 35°C and a pressure of 4MPa Soak for 1-2d;

[0082] The surfactant is in parts by weight, comprising the following raw materials: 3.5 parts of D-mannitol, 1.5 parts of tripotassium phosphate, 3 parts of ethylene glycol, 0.8 part of oleic acid; Potassium, ethylene glycol, and oleic acid were mixed evenly, and ultrasonic treatment was performed for 15 minutes at a temperature of 30°C and a power of 45W to prepare a surfactant;

[0083] The material ratio of described sugarcane tail leaf and corn st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com