Low-temperature koji-making method for soy sauce brewing

A low-temperature, soy sauce technology, applied in the food field, can solve problems such as the inability to guarantee the growth and reproduction of Aspergillus oryzae, the impact on the number of Aspergillus oryzae, and the adverse effects on enzyme activity, so as to reduce the phenomenon of burning koji and bacterial contamination, improve the utilization rate of starch, and reduce biological The effect of the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

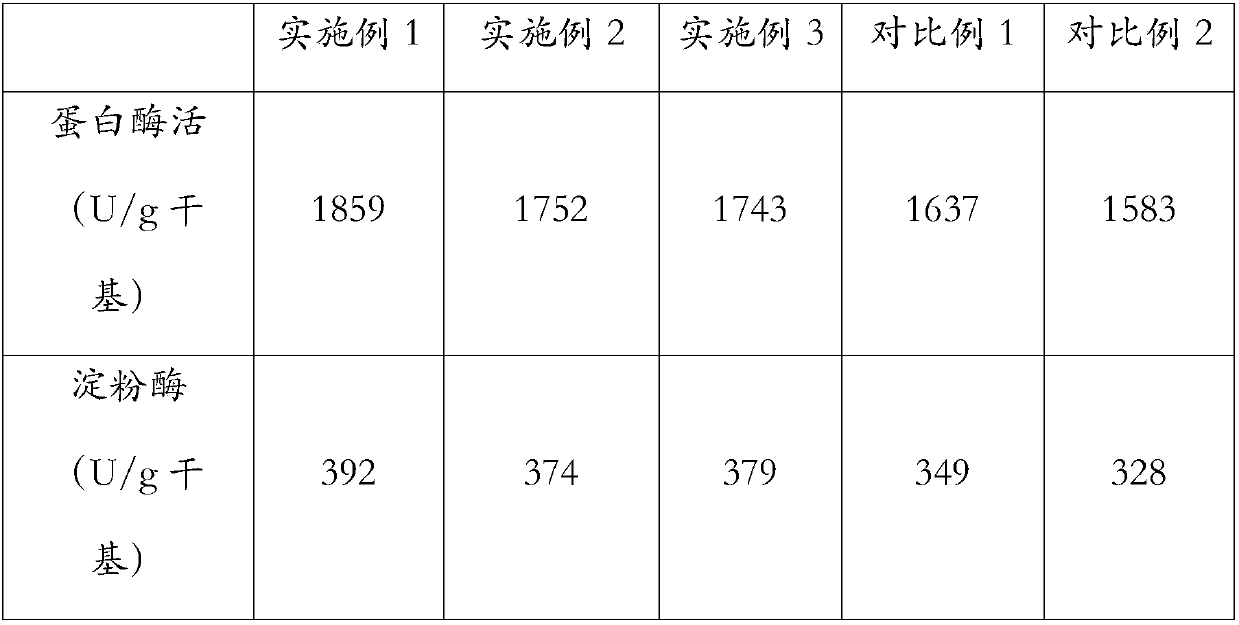

Examples

Embodiment 1

[0023] A low-temperature koji-making method for soy sauce brewing, comprising the following steps:

[0024] 1) Remove impurities and bad beans from soybeans (soybeans), and then soak them at a temperature of about 35° C. for 5 hours according to the mass ratio of soybeans to water of 1:3. The soaked soybeans are then steamed with high-pressure steam for 15 minutes at 0.1 MPa to obtain clinker.

[0025] 2) Mix the Aspergillus oryzae seed koji with flour in advance, and then mix it with cooked yellow material cooled to 35-40°C to make koji material and put it into the koji room for cultivation. Based on the total mass of clinker and flour, the amount of koji added is 0.5%. The clinker and the flour are calculated by mass percentage, the clinker is 85%, and the flour is 15%.

[0026] 3) The thickness of the koji material in the koji pond is maintained at about 10cm, and the temperature is controlled in sections during the koji making process.

[0027] In the first stage, the t...

Embodiment 2

[0033] A low-temperature koji-making method for soy sauce brewing, comprising the following steps:

[0034] 1) Remove impurities and bad beans from soybeans (soybeans), and then soak them at a temperature of about 35° C. for 5 hours according to the mass ratio of soybeans to water of 1:3. The soaked soybeans are then steamed with high-pressure steam for 15 minutes at 0.1 MPa to obtain clinker.

[0035] 2) Mix the Aspergillus oryzae seed koji with flour in advance, and then mix it with cooked yellow material cooled to 35-40°C to make koji material and put it into the koji room for cultivation. Based on the total mass of clinker and flour, the amount of koji added is 0.5%. The clinker and the flour are calculated by mass percentage, the clinker is 85%, and the flour is 15%.

[0036] 3) The thickness of the koji material in the koji pond is maintained at about 10cm, and the temperature is controlled in sections during the koji making process.

[0037] In the first stage, the t...

Embodiment 3

[0043] A low-temperature koji-making method for soy sauce brewing, comprising the following steps:

[0044] 1) Remove impurities and bad beans from soybeans (soybeans), and then soak them at a temperature of about 35° C. for 5 hours according to the mass ratio of soybeans to water of 1:3. The soaked soybeans are then steamed with high-pressure steam for 15 minutes at 0.1 MPa to obtain clinker.

[0045] 2) Mix the Aspergillus oryzae seed koji with flour in advance, and then mix it with cooked yellow material cooled to 35-40°C to make koji material and put it into the koji room for cultivation. Based on the total mass of clinker and flour, the amount of koji added is 0.5%. The clinker and the flour are calculated by mass percentage, the clinker is 85%, and the flour is 15%.

[0046] 3) The thickness of the koji material in the koji pond is maintained at about 10cm, and the temperature is controlled in sections during the koji making process.

[0047] In the first stage, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com