Method for improving particle size distribution concentration degree of cigarette aerosols

A particle size distribution and aerosol technology, applied in tobacco, tobacco preparation, tobacco treatment, etc., to achieve the effects of concentrated distribution, improved sensory quality, and increased deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The additive composed of glycerol and furanone at a ratio of 100:1 is prepared into an additive solution with a mass concentration of 25% by using ethanol-water with a volume ratio of 1:1 as a solvent, and sprays 92.3 per kilogram of tobacco leaves during the tobacco leaf feeding process. Add 1 gram of additive solution to the tobacco leaves, then make shredded tobacco according to the conventional shredding process, and roll it into cigarettes. The theoretical addition amount of additives in each cigarette is 15 mg (the amount of tobacco leaves in each cigarette is calculated on the basis of 0.65 g).

[0021] Control sample: Spray ethanol-water with a volume ratio of 1:1 on the tobacco leaves during the tobacco leaf feeding process, and then make shredded tobacco according to the conventional silk-making process, and roll it into cigarettes. The addition of ethanol-water to each cigarette The amount is the same as that used in the added sample.

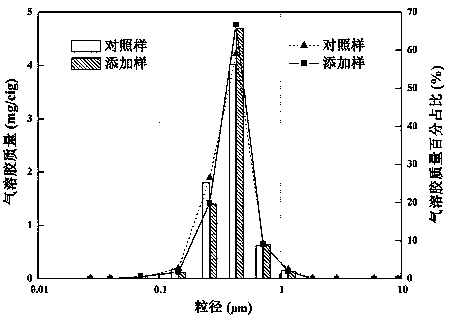

[0022] figure 1 This ...

Embodiment 2

[0024] The ratio of glycerol and furanone is 50:1, and the additive solution composed of glycerol and furanone is prepared into an additive solution with a mass concentration of 40% with pure ethanol, and the prepared additive solution is sprayed with 0.2 gram of additive solution per kilogram of tobacco shredded tobacco in the process of perfuming tobacco shreds. Tobacco, and rolled into cigarettes, the theoretical addition amount of additives in each cigarette is 0.05 mg (the amount of shredded tobacco in each cigarette is calculated as 0.63 g).

[0025] Control sample: ethanol was sprayed on the shredded tobacco during the process of flavoring the shredded tobacco, and rolled into cigarettes. The amount of ethanol added to each cigarette was the same as that used in the added sample.

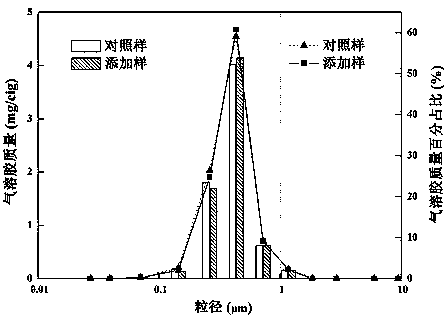

[0026] figure 2 This is a comparison chart of the particle size distribution of the aerosol of cigarette smoke with additives and the control sample. The results show that the aerosol mass o...

Embodiment 3

[0028] The additive composed of glycerol and furanone at a ratio of 150:1 is prepared into an additive solution with a mass concentration of 30% using triacetic anhydride grease as a solvent, and the prepared additive solution is sprayed according to the weight of each kilogram of tow during the filter rod forming process 119.0 grams of the additive solution are sprayed on the filter tow, and then made into a filter rod according to the conventional process, and finally rolled into cigarettes, the theoretical addition amount of the additive in each cigarette is 5 mg (the amount of the tow in each cigarette is based on 0.14 g meter).

[0029] Control sample: Spray triacetic anhydride oil on the filter tow during the filter rod forming process, then make filter rods according to the conventional process, and finally roll into cigarettes. The same amount was used in the samples.

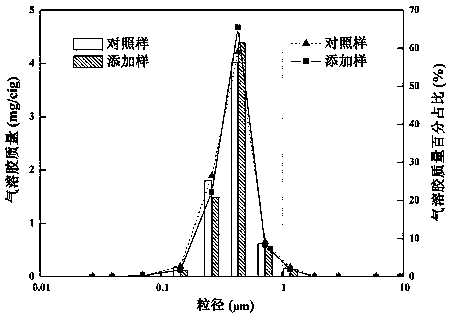

[0030] image 3 It is a comparison chart of the particle size distribution of the aerosol of cigar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com