A kind of bismuth arsenic beneficiation separation method

A separation method and technology of ore counting, applied in solid separation, flotation and other directions, can solve problems such as no technical measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

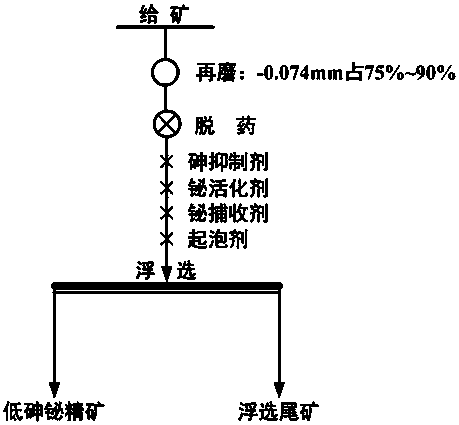

[0033] The ore feeding of this embodiment is a rough concentrate of bismuth and arsenic in a place in Yunnan, China, and the process steps are as attached figure 1 shown, including the following steps:

[0034] S1. Grinding the bismuth arsenic rough concentrate to -0.074mm accounts for 84%;

[0035] S2. Drug removal: add water to the product after grinding to adjust the pulp concentration to 55%, heat it to 90°C, and keep it warm for 1.5 hours to obtain the rough concentrate after drug removal;

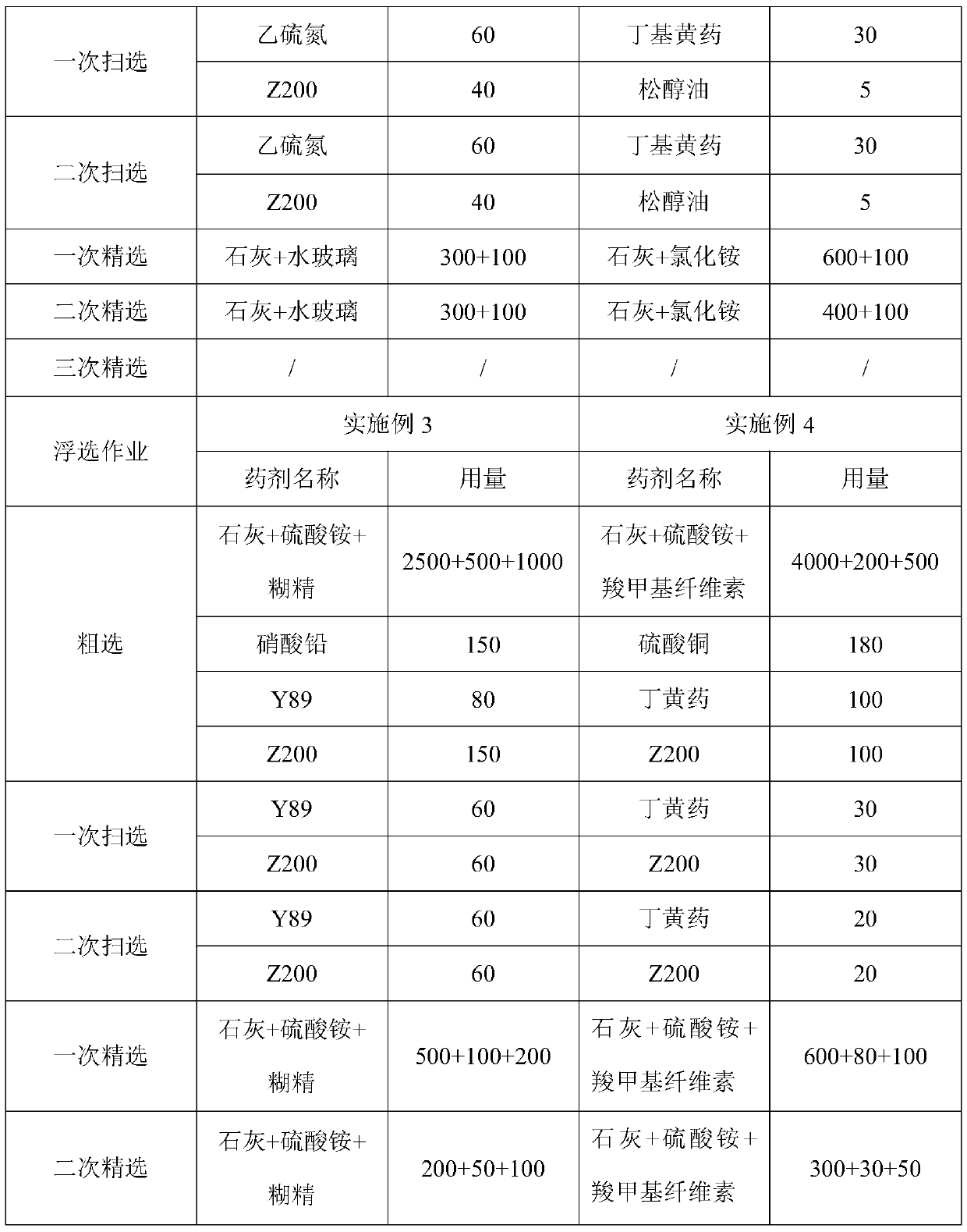

[0036] S3. Add water to the coarse concentrate after drug removal to adjust the pulp concentration to 33%, and feed it into flotation to obtain low-arsenic bismuth concentrate and flotation tailings. As shown below, the drug addition conditions are shown in Table 1, and the obtained indexes are shown in Table 2.

[0037] S31. Rough selection: Add arsenic inhibitor and stir according to the feed per ton; then add bismuth activator and stir; then add bismuth collector and stir; finall...

Embodiment 2

[0042] The ore feeding of this embodiment is a rough concentrate of bismuth and arsenic in a certain place in Guangxi, China, and the process steps are as attached figure 1 shown, including the following steps:

[0043] S1. Grinding the bismuth arsenic rough concentrate to -0.074mm accounts for 81%;

[0044] S2. Add water to the product after grinding until the pulp concentration is 45%. Add 5000g / t of sodium sulfide, stir for 5 minutes, add 2000g / t of lime, stir for 3 minutes, add water to adjust the pulp to the pulp The concentration is 10%, concentrated and dehydrated to a pulp concentration of 60%, adding water again to adjust the pulp concentration to 10%, and concentrating to a pulp concentration of 60%, to obtain a rough concentrate after de-drugs;

[0045] S3. Add water to the coarse concentrate after drug removal to adjust the pulp concentration to 26%, and feed it into flotation to obtain low-arsenic bismuth concentrate and flotation tailings. The types of chemicals...

Embodiment 3

[0051] In this embodiment, the ore feed is a rough concentrate of bismuth and arsenic in a certain place in Inner Mongolia, China, and the process steps are as attached figure 1 shown, including the following steps:

[0052] S1. Grinding the bismuth arsenic rough concentrate to -0.074mm accounts for 89%;

[0053] S2. Add water to the product after grinding to adjust the pulp concentration to 50%, and add 5000g / t of activated carbon per ton of ore feed, and stir for 5 minutes to obtain the rough concentrate after drug removal;

[0054] S3. Add water to the coarse concentrate after drug removal to adjust the pulp concentration to 31%, and feed it into flotation to obtain low-arsenic bismuth concentrate and flotation tailings. The types of chemicals added in each roughing, sweeping and beneficiation As shown below, the drug addition conditions are shown in Table 1, and the obtained indexes are shown in Table 2.

[0055] S31. Rough selection: Add arsenic inhibitor and stir accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com