Machining method of aircraft large arc-shaped structural part and T-shaped staggered tooth cutter for machining

A technology of arc structure and processing method, applied in metal processing equipment, workpieces, milling cutters, etc., can solve the problems of poor quality of parts, increase the grinding process of fitters, and prolong the overall processing cycle of parts, so as to reduce the influence of human factors, The effect of reducing the fitter's grinding process and shortening the delivery cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

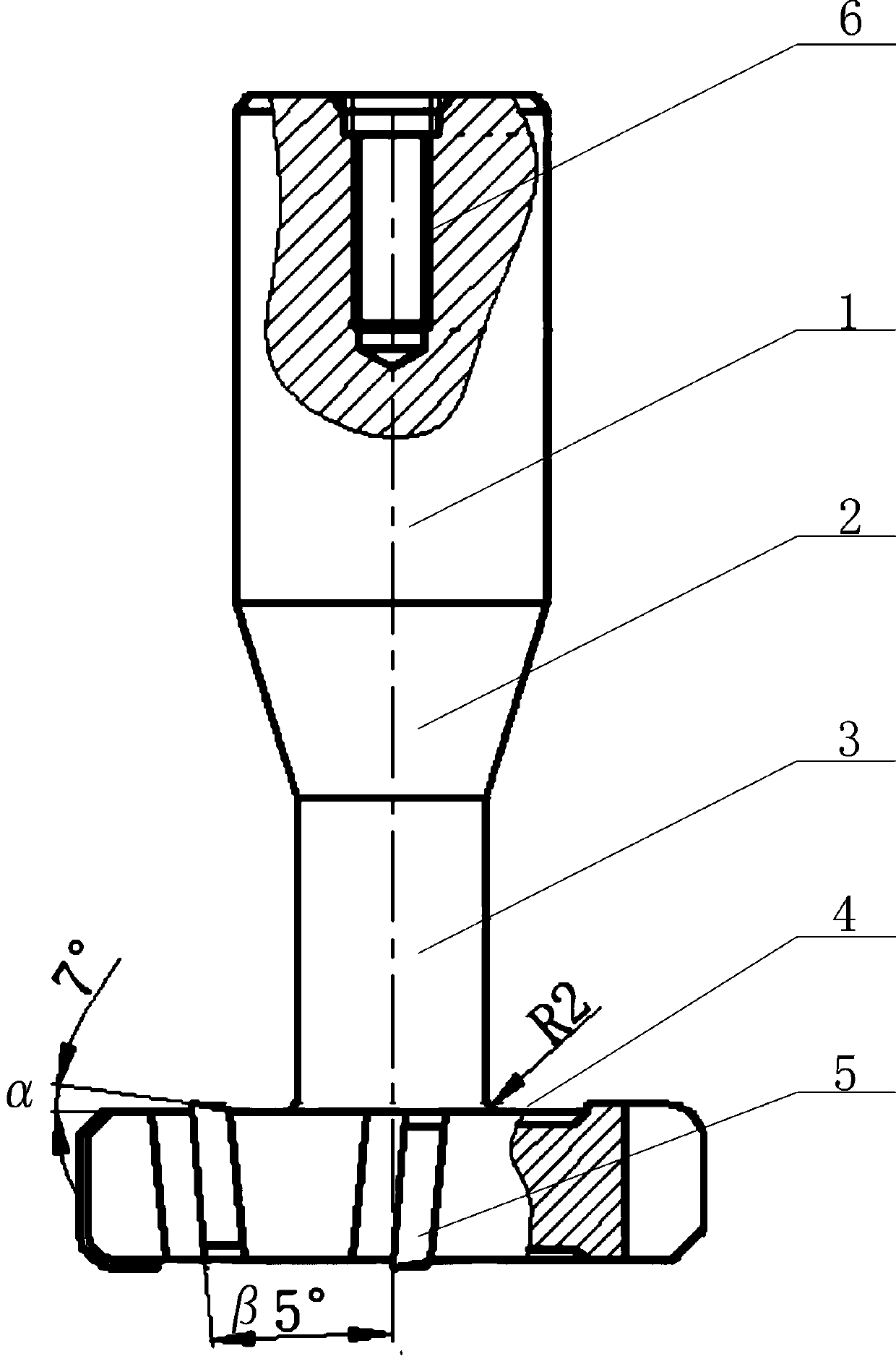

[0036] Such as figure 2 As shown, the present invention provides a kind of cemented carbide staggered-toothed T-shaped knife for processing large-scale arc-shaped structural parts of aircraft, a kind of staggered-toothed T-shaped knife for processing large-scale arc-shaped structural parts of aircraft, which includes handle 1, A knife neck 3 and a knife body 4 , the knife handle 1 is connected to the knife neck 3 through a circular frustum 2 , and the knife neck 3 is connected to the knife body 4 . The diameter of the handle 1 is larger than that of the neck 3 and the truncated body 2, and the shank 1, the truncated body 2, the neck 3 and the body 4 are connected in one body and are T-shaped as a whole.

[0037] The first improvement of the present invention is that the cutting edge 5 of the cutter body 4 is arranged on the upper and lower planes of the cutter body 1 with staggered teeth. Wherein further the cutting edge number of cutter body is set to 6 blades or 8 blades o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com