CCD and CAM optical contour grinder

An optical curve grinding and fuselage technology, applied in the field of CCD, can solve the problems of inability to achieve intelligent and automatic requirements, no CCD mirror pairing group, large workload of staff, etc., to achieve convenient programming and processing, and ensure effective cutting length. , the effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

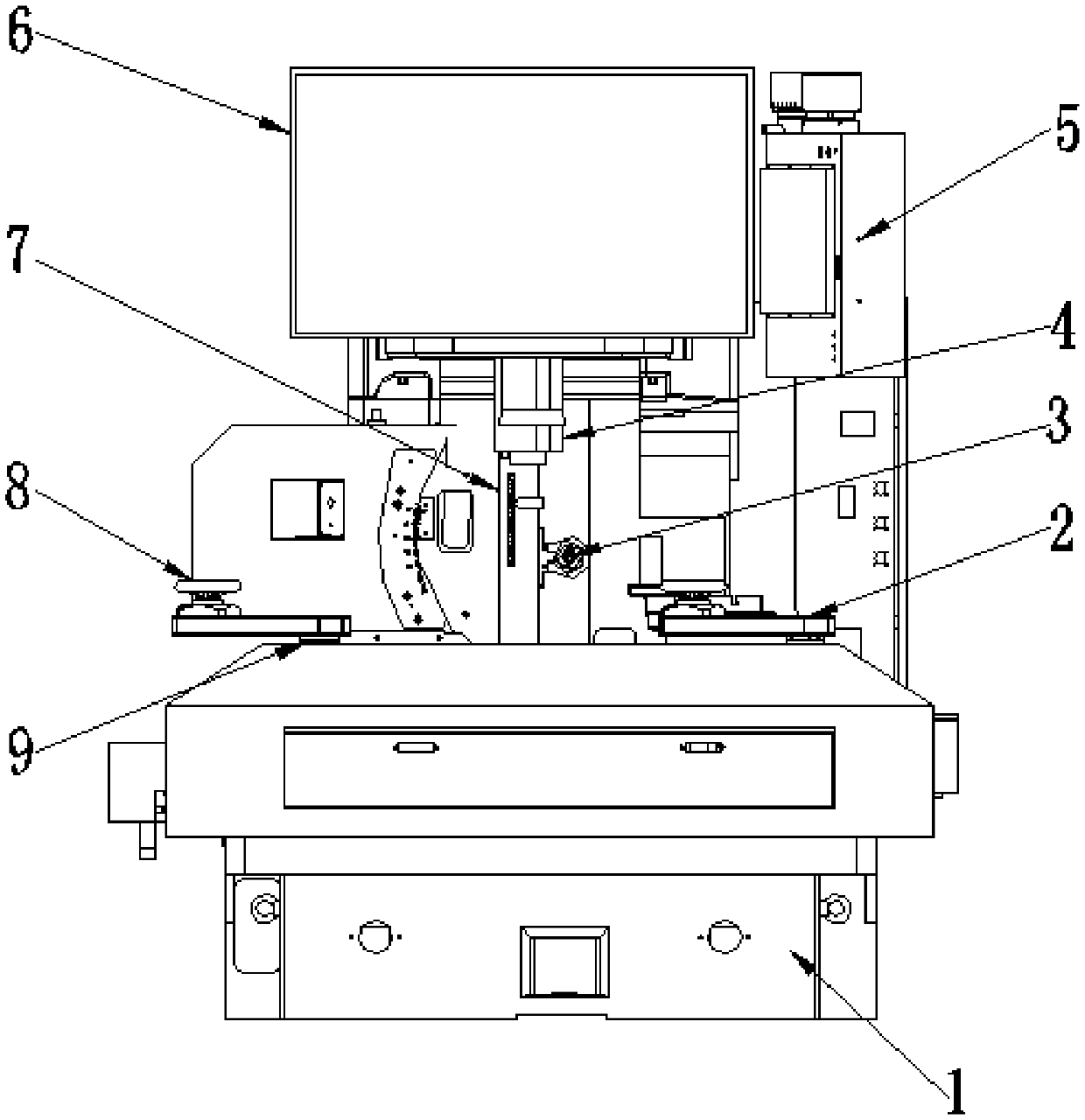

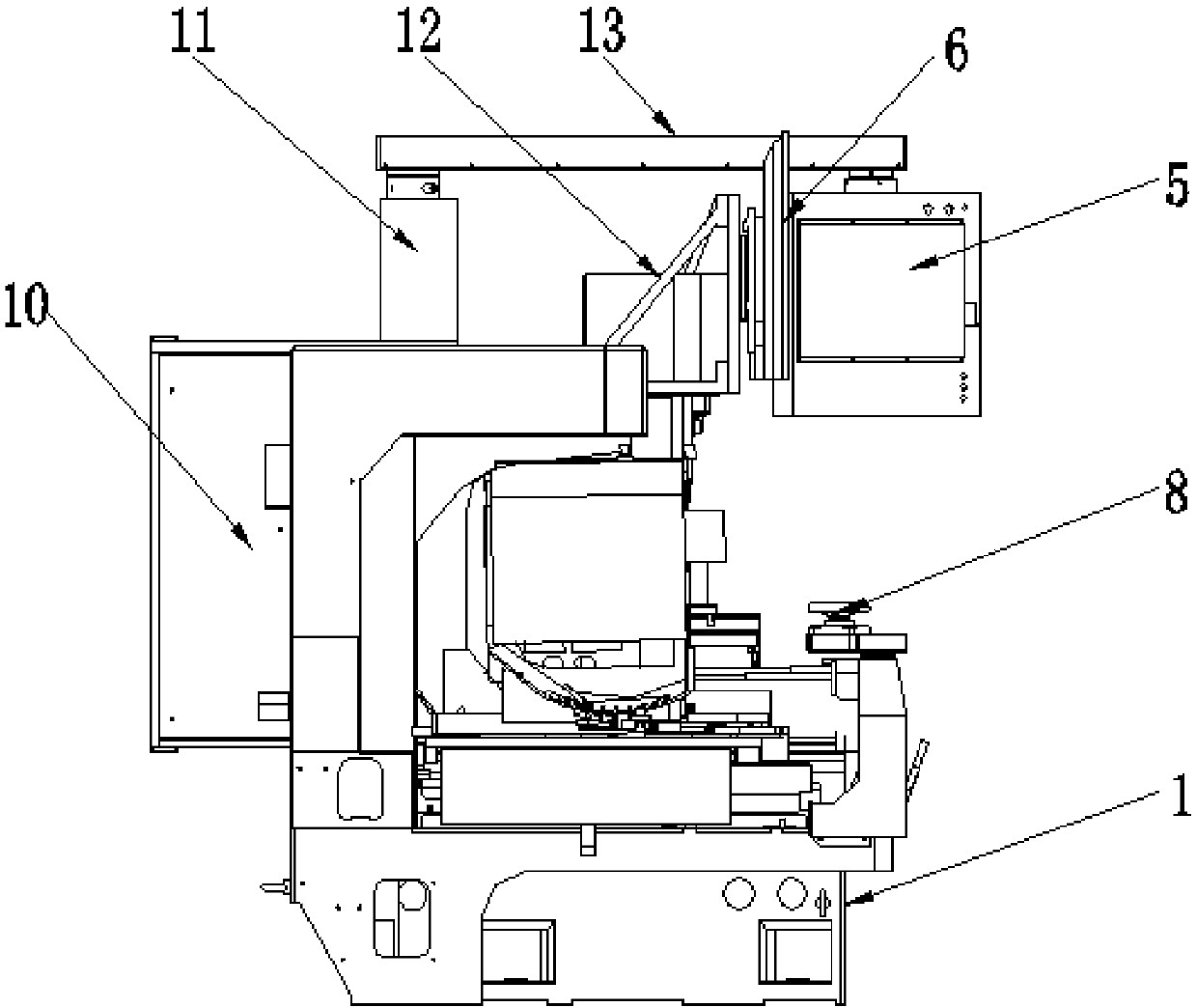

[0017] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a CCD, CAM optical curve grinder, including a lower body 1, a ZV working lifting platform 2, an electric spindle 3, a CCD mirror pair group 4, a control panel 5, a display screen 6, Mechanical reciprocating cutting device 7, hand wheel 8, three pendulum angle device 9, upper body 10, support rod 11, support 12 and rotating rod 13, upper end of lower body 1 is provided with upper body 10, and lower body 1 The upper end is provided with a ZV working lifting platform 2 near the front side of the upper fuselage 10, and a bracket 12 is arranged at the upper end of the upper fuselage 10 near the ZV working lifting platform 2, and the upper end of the upper fuselage 10 is provided with a support Rod 11, an electric spindle 3 is arranged on the front side of the upper body 10 near the lower part of the bracket 12, a display screen 6 is arranged on one end of the bracket 12, and a rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com