Mechanical arm operation control system based on PyQt

An operation control and robotic arm technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problem of not considering robot simulation and trajectory planning functions to expand the compatibility of multiple types of manipulators, inflexible manipulator control operations, and manipulators. Problems such as poor controller compatibility, to achieve the effect of rich interface functions, expanded functionality, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

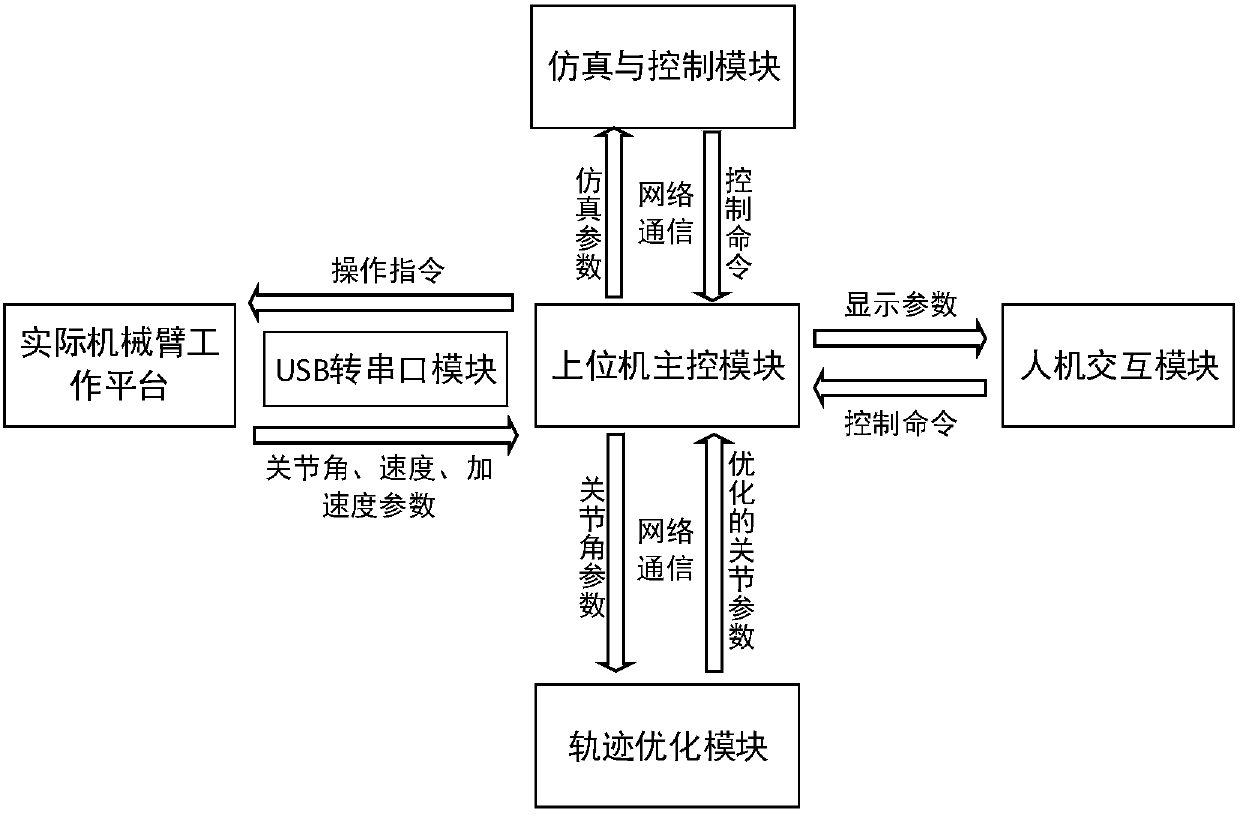

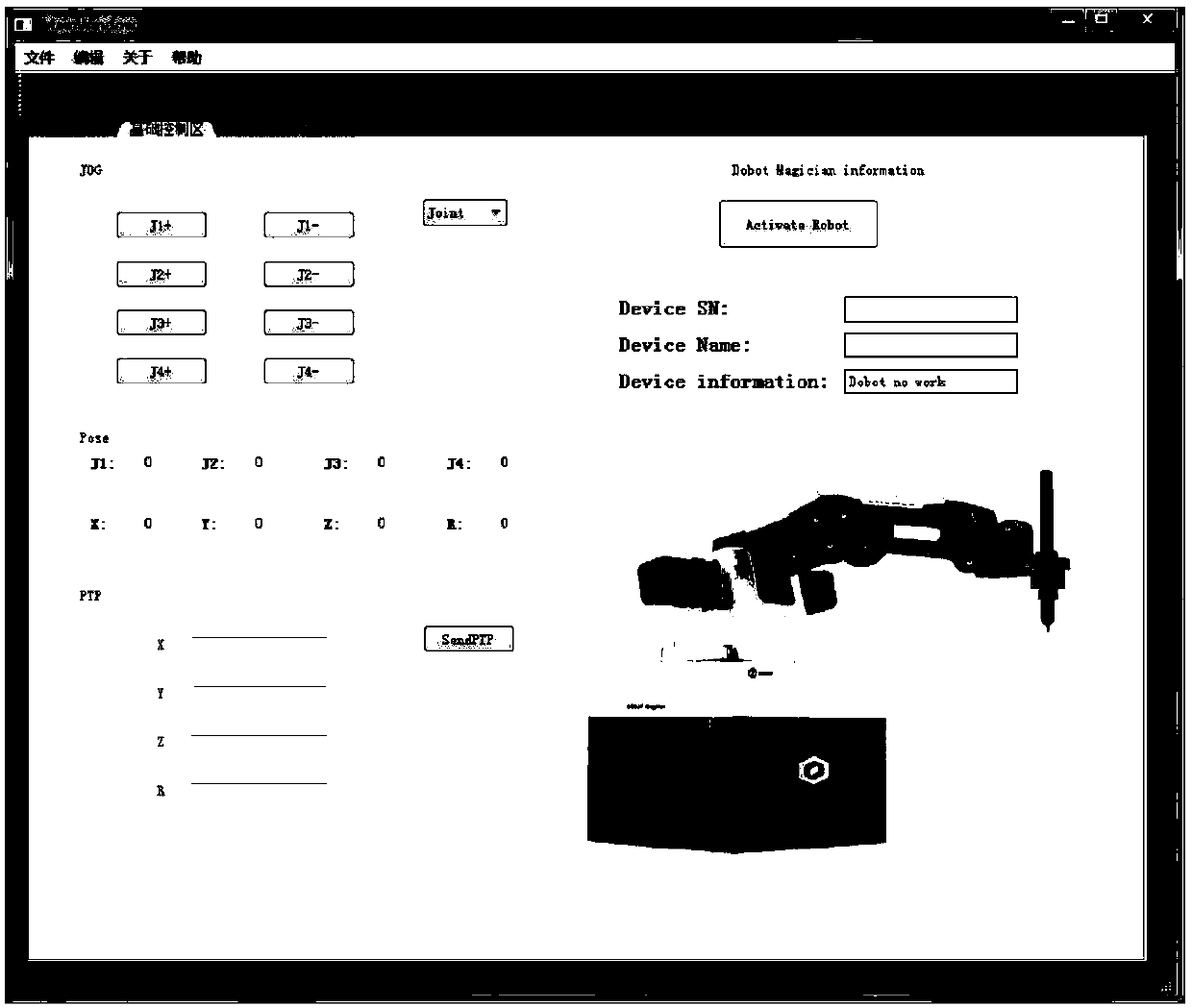

[0043] A PyQt-based manipulator operation control system, the control principle block diagram is as follows figure 1 As shown, the system consists of a human-computer interaction interface module, a host computer main control module, a simulation and control module, a trajectory planning module, and a USB-to-serial port module, a total of five modules. The specific effect of the human-computer interaction module is shown in Figure 2, and its interface consists of three major parts. Including the manipulator connection control interface, the manipulator basic control and related information display interface, the manipulator online teaching and simulation control interface. Each interface is used to control the robotic arm to complete various specific operations and display corresponding operating parameters. image 3 It shows the display effect of the manip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com