A water phase clay adsorbent forming equipment

A technology of clay adsorption and molding equipment, applied in coating and other directions, can solve the problems of high material pressure, inability to large-scale production, and inability to use clay adsorbents on a large scale, and achieve the effect of overcoming cavitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

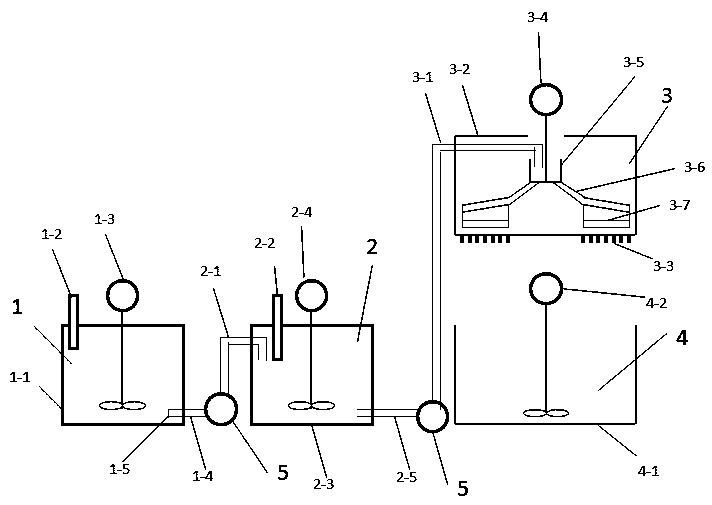

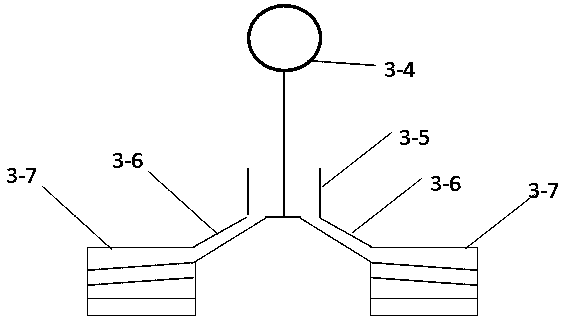

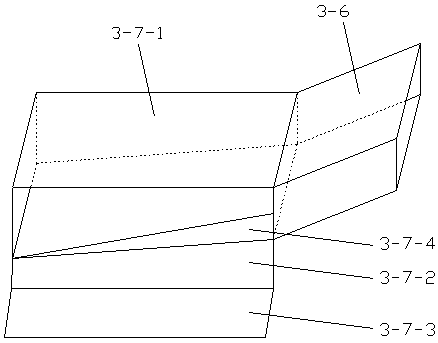

[0031] Such as figure 1 A water-phase clay adsorbent forming equipment shown includes a PVA hot-melt device 1 , a feed mixing device 2 , a forming device 3 , a solidifying device 4 and a material delivery pump 5 .

[0032] The PVA hot melting device 1 includes a constant temperature heating reaction cylinder 1-1, a feed inlet 1-2, a PVA agitator 1-3 and a PVA discharge pipe 1-4. Materials such as solid PVA, water and sodium alginate are added into the constant temperature heating reaction cylinder 1-1 through the feed port 1-2 in proportion. It starts to dissolve at 90°C, and the high temperature of 105±2°C can make the molten material boil slightly, and the stirring of PVA mixer 1-3 can make the PVA with larger particles dissolve quickly and fully; in order to prevent possible Incompletely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com