3D composite sheet and its preparation method

A composite plate and composite substrate technology, which is applied in chemical instruments and methods, synthetic resin layered products, metal material coating technology, etc., can solve the problems of 3D composite plates that cannot be mass-produced and yielded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

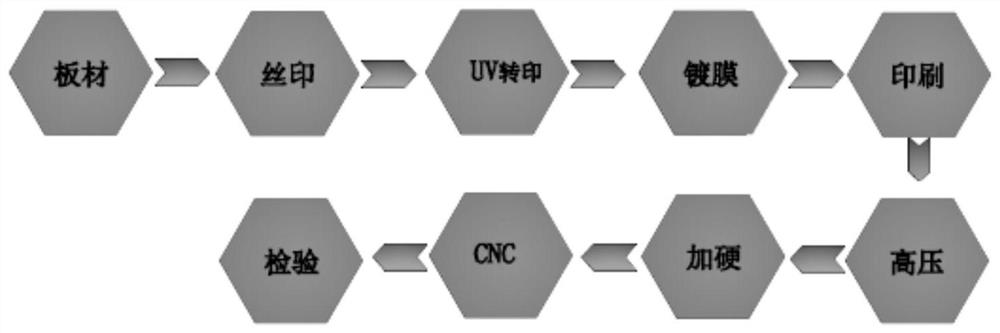

[0041] A method for preparing a 3D composite plate, comprising the following steps:

[0042] Pretreatment of the composite substrate;

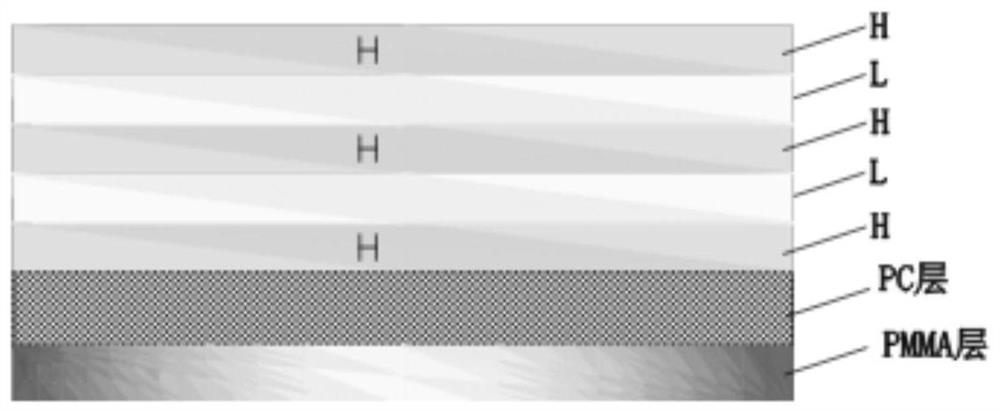

[0043] The method of electron beam evaporation is adopted, and the material with a refractive index of 2-3 and the material with a refractive index of 1.4-1.6 are respectively used as coating materials, and the coating is alternately performed on the composite substrate after pretreatment. The process of each coating The parameters include: the coating rate is

[0044] The coated composite substrate is subjected to high pressure or hot bending forming.

[0045] Specifically, the pre-treatment includes the steps of screen printing and UV (ultraviolet) transfer printing on the composite substrate. Before silk screen printing, the composite substrate can also be cleaned.

[0046]Preferably, the composite substrate is a PC / PMMA (polycarbonate / polymethyl methacrylate) composite board. Screen printing a layer of transparent / translucent ink on ...

Embodiment 1

[0069] This embodiment provides a method for preparing a 3D composite sheet, the preparation process of which is as follows figure 1 shown, including the following steps:

[0070] a. Clean the surface of the PC / PMMA composite board with a flat-panel cleaning agent for subsequent screen printing and UV transfer processing, and do not add chemicals during cleaning.

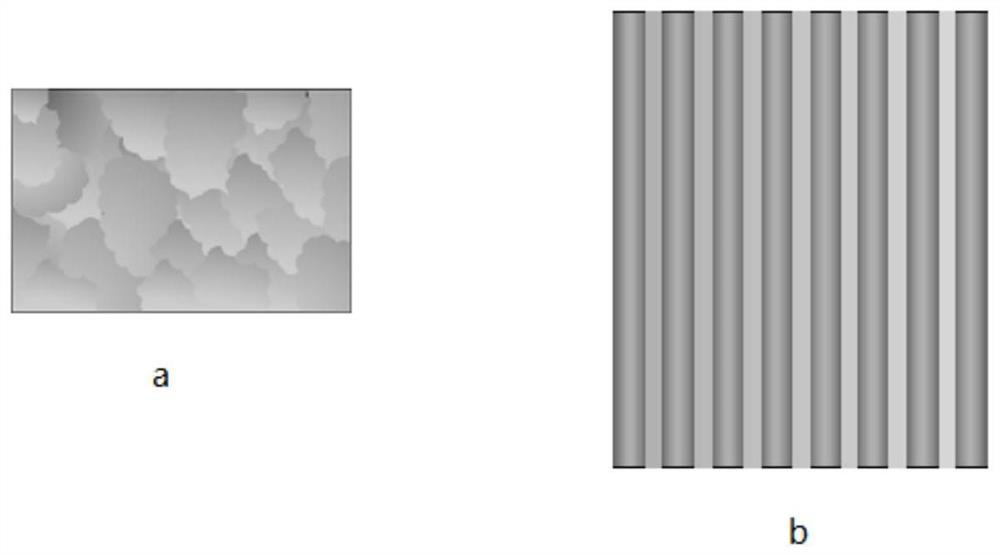

[0071] b. Screen-print a layer of transparent / translucent ink on the PC / PMMA composite board to make the product visually grainy and three-dimensional.

[0072] c. Apply a layer of UV transfer glue on the PC / PMMA composite board after step b, use a UV transfer machine to print the required texture or pattern on the surface of the glue, and then cure the glue through a UV furnace, and then Enter the coating process. In this step, the UV transfer glue adopts glue with fast curing, high bonding strength, good toughness, impact resistance, and excellent cold and heat resistance. The thickness of the texture or pattern...

Embodiment 2

[0080] This embodiment provides a method for preparing a 3D composite sheet, comprising the following steps:

[0081] a. Clean the surface of the PC / PMMA composite board with a flat-panel cleaning agent for subsequent screen printing and UV transfer processing, and do not add chemicals during cleaning.

[0082] b. Screen-print a layer of transparent / translucent ink on the PC / PMMA composite board to make the product visually grainy and three-dimensional.

[0083] c. Apply a layer of UV transfer glue on the PC / PMMA composite board after step b, use a UV transfer machine to print the required texture or pattern on the surface of the glue, and then cure the glue through a UV furnace, and then Enter the coating process. In this step, the UV transfer glue adopts glue with fast curing, high bonding strength, good toughness, impact resistance, and excellent cold and heat resistance. The thickness of the texture or pattern formed after the glue is cured is 10 μm.

[0084] d. After fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com