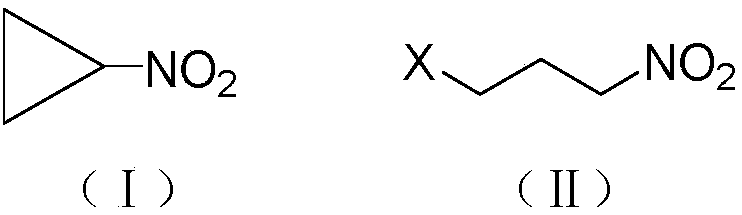

Synthesis method of nitrocyclopropane

A technology of nitrocyclopropane and nitropropane, which is applied in the field of synthesis of pharmaceutical and pesticide intermediates, and can solve the problems of low yield and no application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

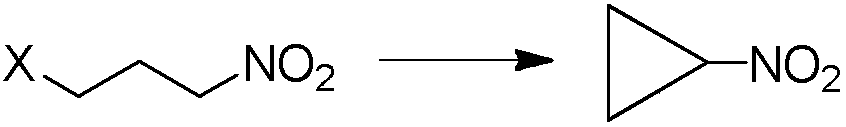

Method used

Image

Examples

Embodiment 1

[0015] At 0°C, 30 mL of dichloromethane, 3 g (0.075 mol) of sodium hydroxide and 0.05 g (2.2×10 -4 mol) benzyltriethylammonium chloride, and then 10.8 grams (0.05mol) of 1-iodo-3-nitropropane was added dropwise. After the dropwise addition, the temperature was raised, refluxed for 0.5 hours, and cooled to room temperature. The reaction solution was washed twice with water and separated. The organic phase was dried over anhydrous sodium sulfate and evaporated to dryness to obtain 5.2 g of a light yellow transparent liquid. It was confirmed to be nitrocyclopropane by NMR analysis, with a yield of 92.6% and a purity of 95.2%.

[0016] 1 H NMR (CDCl 3 ,500MHz,δ / ppm):4.25(m,1H),1.64(m,2H),1.15(m,2H).

Embodiment 2

[0018] At 0°C, 30 mL of ethyl acetate, 4 g (0.1 mol) of sodium hydroxide and 0.11 g (5×10 -4 mol) benzyltriethylammonium chloride, and then 8.4 grams (0.05mol) of 1-bromo-3-nitropropane were added dropwise. After the dropwise addition, the temperature was raised to 60° C. to react for 1 hour, and then cooled to room temperature. The reaction solution was washed twice with water and separated. The organic phase was dried over anhydrous sodium sulfate and evaporated to dryness to obtain 5 g of a light yellow transparent liquid. It was confirmed to be nitrocyclopropane by NMR analysis, with a yield of 88.2% and a purity of 94%.

Embodiment 3

[0020] At 0°C, 30 mL of toluene, 4 g (0.1 mol) of sodium hydroxide and 0.05 g (2.2×10 - 4 mol) benzyltriethylammonium chloride, and then 6.2 grams (0.05mol) of 1-chloro-3-nitropropane were added dropwise. After the dropwise addition, the temperature was raised to 100° C. to react for 1 hour, and then lowered to room temperature. The reaction solution was washed twice with water and separated. The organic phase was dried over anhydrous sodium sulfate and evaporated to dryness to obtain 5 g of a light yellow transparent liquid. It was confirmed as nitrocyclopropane by NMR analysis, with a yield of 89.1% and a purity of 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com