Chemical synthetic method of 2-hydroxybenzimidazole

A technology for hydroxybenzimidazole and chemical synthesis, applied in the direction of organic chemistry, etc., can solve the problems of low conversion rate of 2-hydroxybenzimidazole and long synthesis time, and achieve the effects of high conversion rate and low energy consumption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

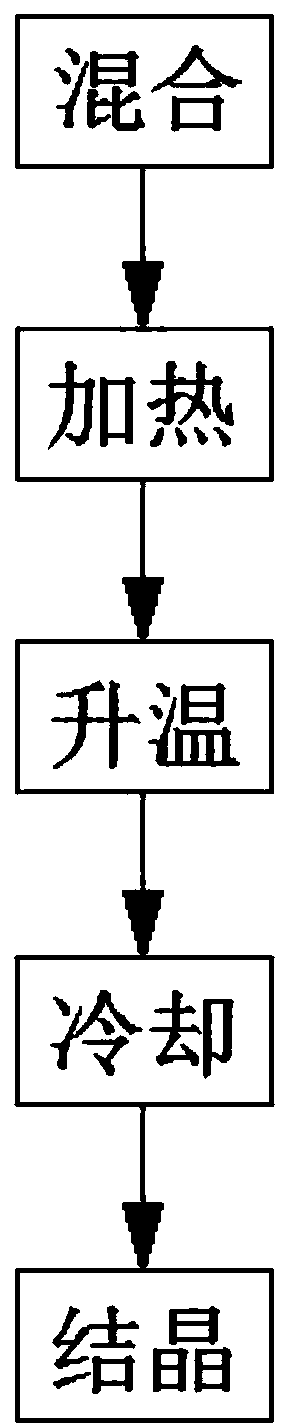

[0020] see figure 1 , the present invention provides a kind of chemical synthesis method of 2-hydroxybenzimidazole, the synthetic raw material of described 2-hydroxybenzimidazole comprises: o-phenylenediamine, acid, catalyst and sodium hydroxide, and described 2-hydroxybenzimidazole The chemical synthesis method of imidazole comprises the steps:

[0021] S1: Mixing: Mix the acid and o-phenylenediamine, stir evenly, and then use a ball mill to fully ball mill;

[0022] S2: Heating: put the ball-milled powder in step S1 into a round-bottomed flask, add a catalyst, then heat in an oil bath to 120 degrees Celsius, stir and keep warm for 2 hours;

[0023] S3: heating up: raise the temperature to 160 degrees Celsius, and use microwave radiation to keep warm for 5 hours;

[0024] S4: Cooling: After the reaction is finished, cool, pour into distilled water, use sodium hydroxide solution to neutralize the precipitated solution until the pH is 8.2, filter with suction, wash, and dry t...

Embodiment 2

[0029] see figure 1 , the present invention provides a kind of chemical synthesis method of 2-hydroxybenzimidazole, the synthetic raw material of described 2-hydroxybenzimidazole comprises: o-phenylenediamine, acid, catalyst and sodium hydroxide, and described 2-hydroxybenzimidazole The chemical synthesis method of imidazole comprises the steps:

[0030] S1: Mixing: Mix the acid and o-phenylenediamine, stir evenly, and then use a ball mill to fully ball mill;

[0031] S2: Heating: put the ball-milled powder in step S1 into a round-bottomed flask, add a catalyst, then heat in an oil bath to 100 degrees Celsius, stir and keep warm for 1 hour;

[0032] S3: heating up: raise the temperature to 140 degrees Celsius, and use microwave radiation to keep warm for 3 hours;

[0033] S4: Cooling: After the reaction is completed, cool, pour into distilled water, use sodium hydroxide solution to neutralize the precipitated solution to a pH of 7.8, suction filter, wash, and dry to obtain a...

Embodiment 3

[0038] see figure 1 , the present invention provides a chemical synthesis method of 2-hydroxybenzimidazole, the synthetic raw materials of said 2-hydroxybenzimidazole include: o-phenylenediamine, acid, catalyst and sodium hydroxide, said 2-hydroxybenzimidazole The chemical synthesis method of imidazole comprises the steps:

[0039] S1: Mixing: Mix the acid and o-phenylenediamine, stir evenly, and then use a ball mill to fully ball mill;

[0040] S2: Heating: Put the ball-milled powder in step S1 into a round-bottomed flask, add a catalyst, then heat in an oil bath to 110 degrees Celsius, stir and keep warm for 1.5 hours;

[0041] S3: heating up: raise the temperature to 150 degrees Celsius, and use microwave radiation to keep warm for 4 hours;

[0042] S4: Cooling: After the reaction is finished, cool, pour into distilled water, use sodium hydroxide solution to neutralize the precipitated solution to a pH of 8, filter with suction, wash, and dry to obtain a crude product;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com