Super large vertical continuous anaerobic fermentation tank

An anaerobic fermenter and super-large technology, applied in the field of biological resource recycling, can solve the problems such as the lack of any advantages in the commercial competition of biological natural gas, the limited raw materials of biological natural gas products, and the development of industrialization and industrialization, etc., and increase the number of processed raw materials. It is beneficial to the intensification of production and the effect of improving the efficiency of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

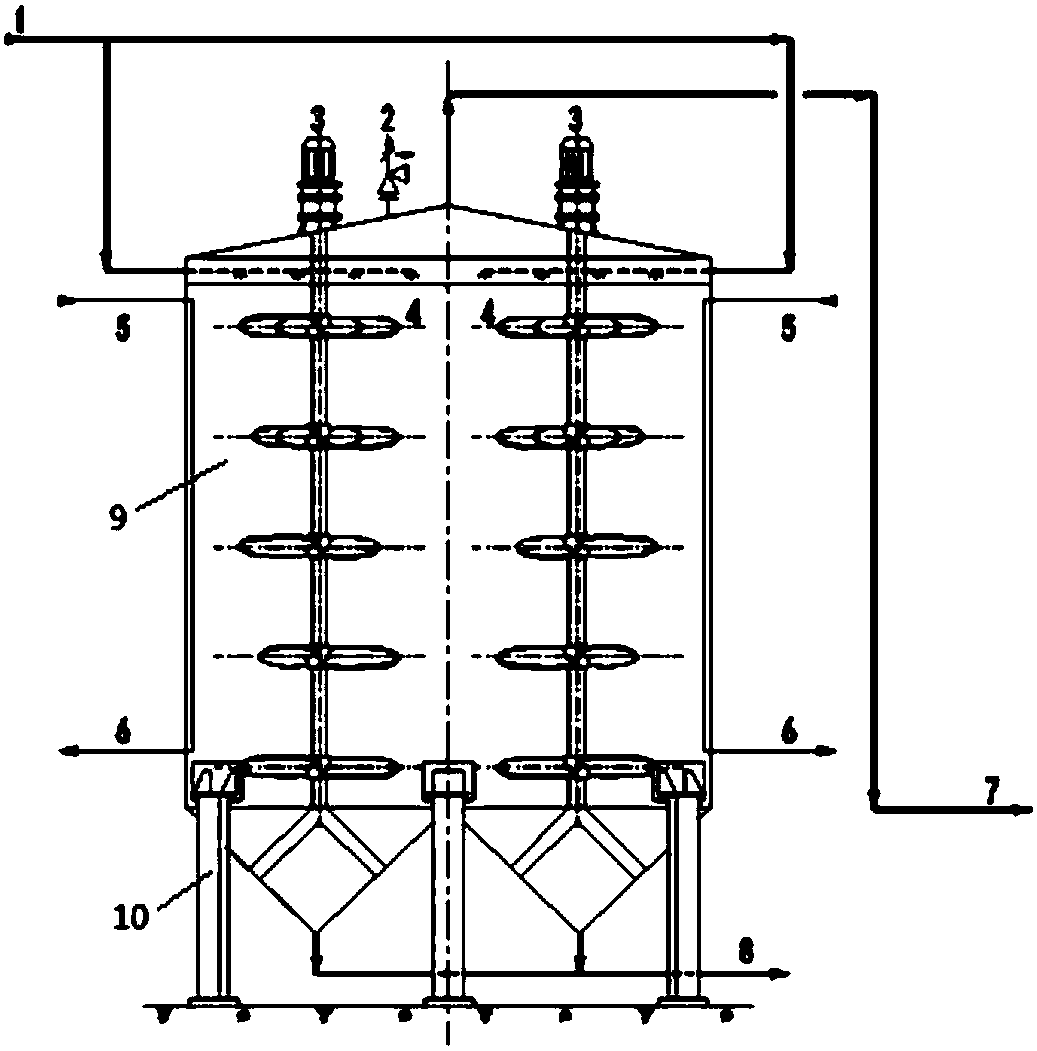

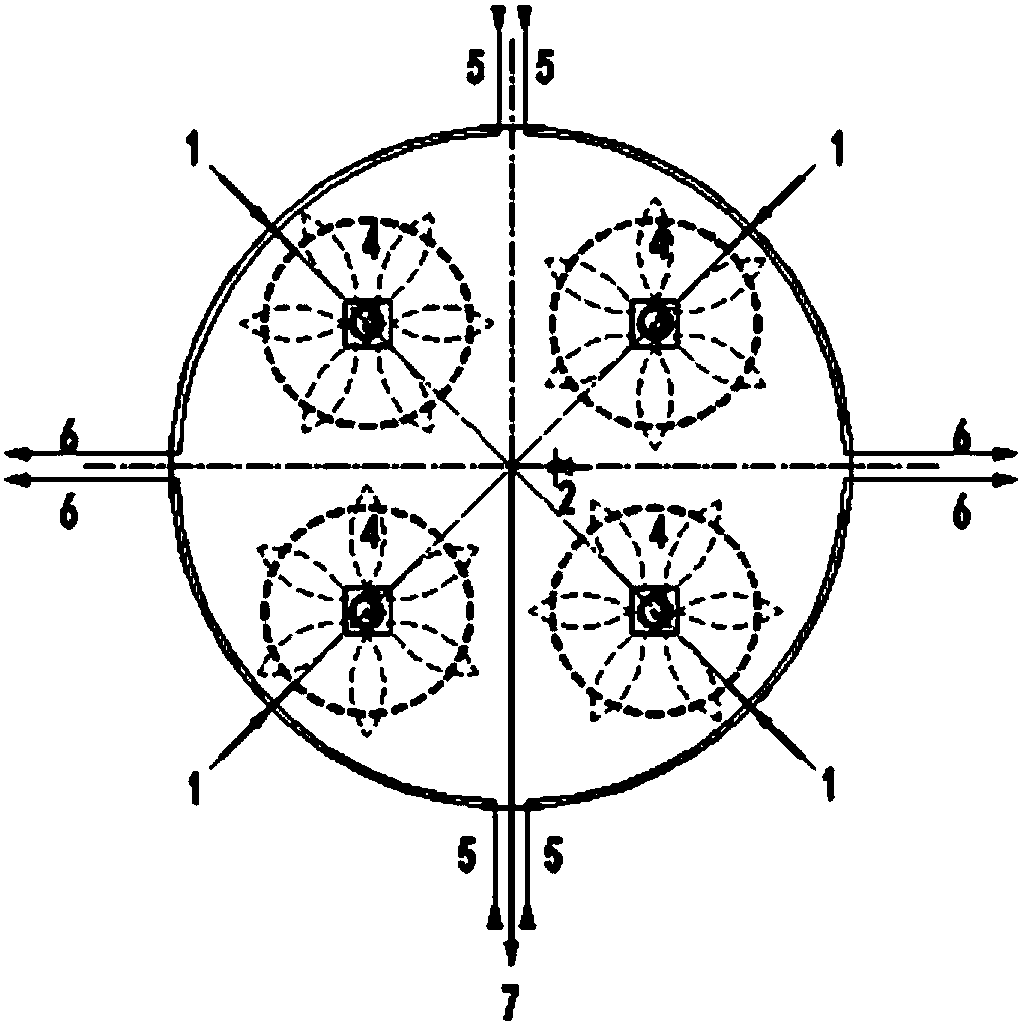

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0018] See Figure 1-2 , the present invention relates to a super-large vertical continuous anaerobic fermentation tank, comprising a tank body 9, a raw material inlet pipe 1, a pressure protection device 2, a stirring device 3, a heat preservation water pipe, a biogas discharge pipe 7, a biogas residue discharge pipe 8 and branch Seat 10, the tank body 9 is a sealed steel structure storage tank consisting of a vertical conical top, a circular hollow body and a conical bottom, wherein the conical bottom is a plurality of inverted conical structures, and the tank body 9 is provided with The support 10 is fixedly installed on the ground; the raw material inlet pipe 1 is 4, uniformly distributed on the top of the tank body 9; the pressure protection device 2 is arranged on the vertical cone top of the tank body 9; the stirring Device 3 is 4 groups, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com