A pre-treatment process of metal surface atomization and spraying

A technology of atomization spraying and metal surface, which is applied in the direction of metal material coating process, etc., can solve the problems affecting the quality and service life of the film on the treatment liquid, the increase of the metal ion content, and the gradual change, so as to improve the quality of the film. Quality and film uniformity, reduce production costs, and maintain stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0057] For silanization treatment, use silane treatment liquid.

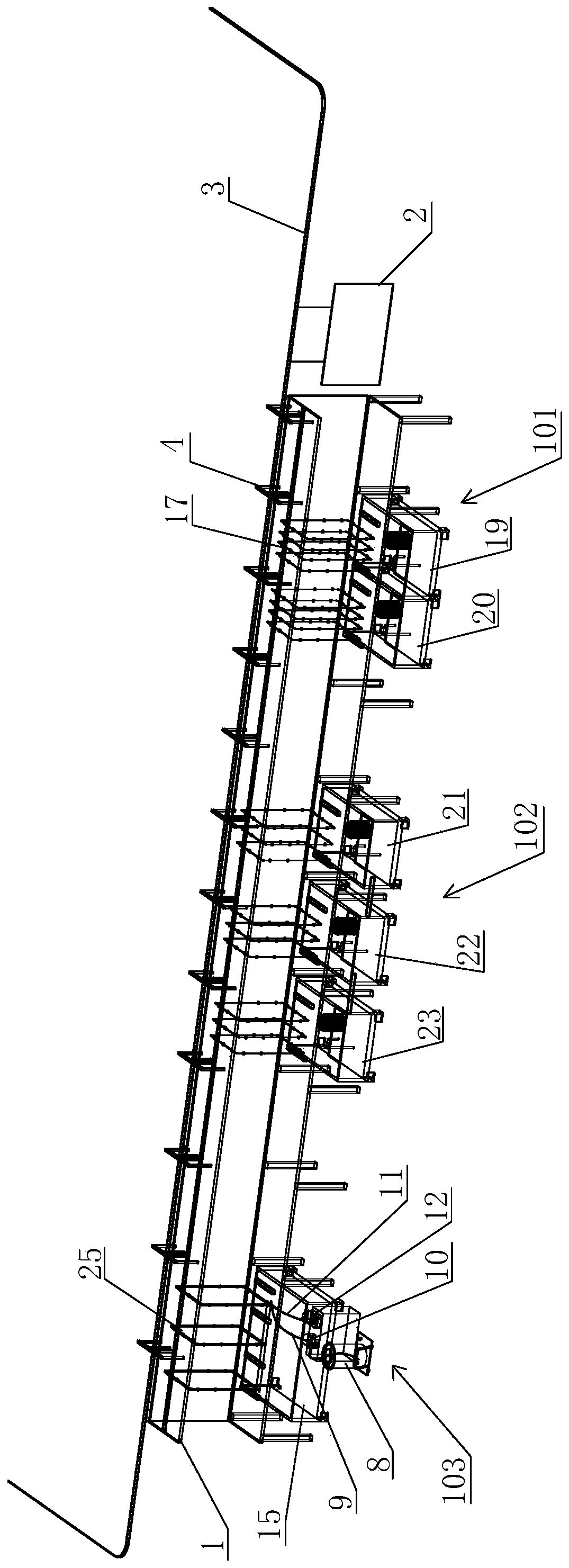

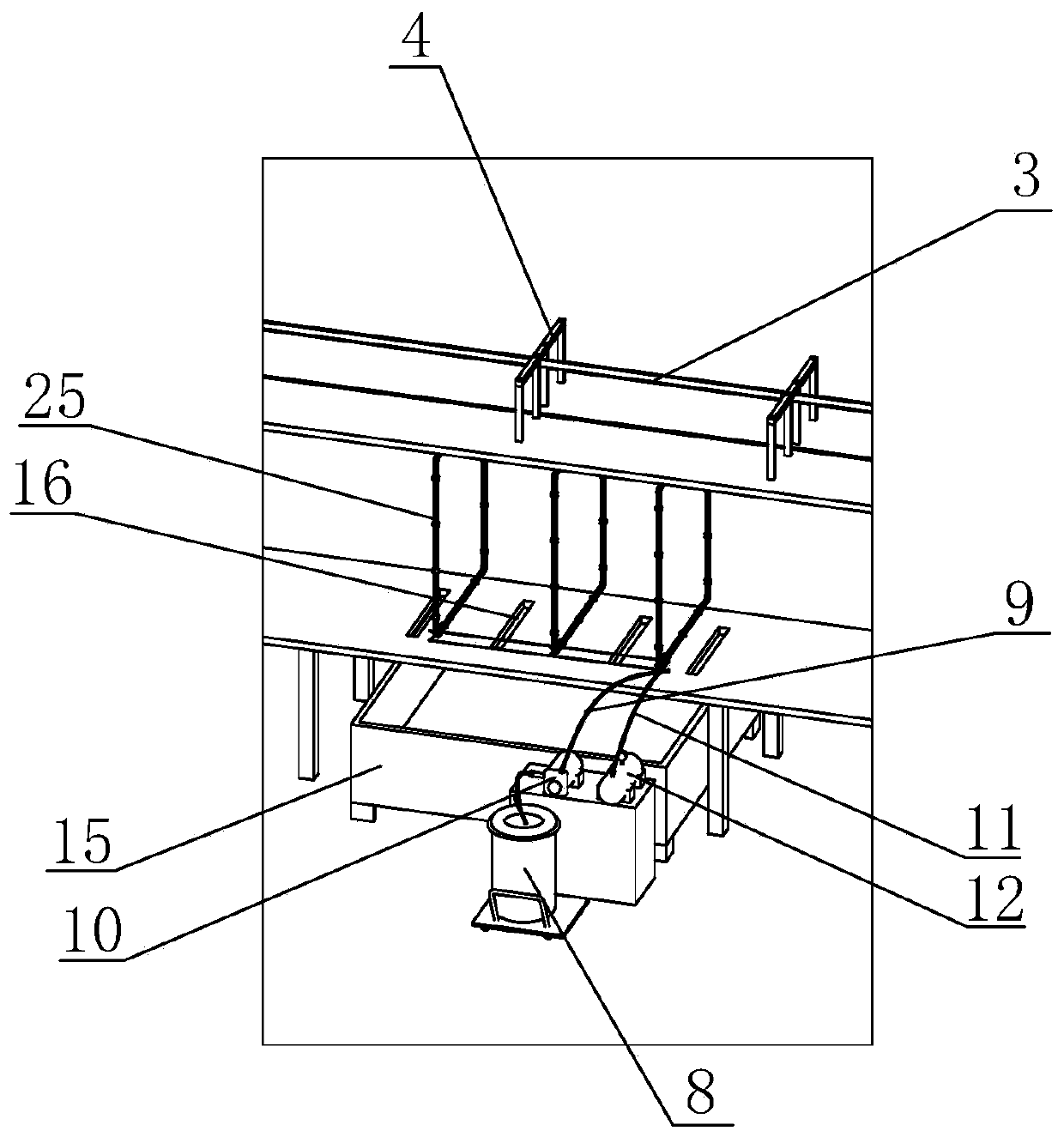

[0058] Assembly line parameters: assembly line speed 5m / s; processing box height 2.4m, width 1.5m.

[0059] Hang the metal sheets or workpieces that need to be pre-treated on the assembly line, and the assembly line drives the metal sheets or workpieces to undergo pre-degreasing, main degreasing, and three washings in sequence. The treatment process is all in the form of spraying. Then, the degreasing and water-washed metal plates or workpieces are subjected to coating treatment, and the prepared silane treatment solution is poured into the treatment solution storage barrel. Insert one end of the treatment liquid delivery main pipe into the silane treatment liquid, turn on the pressure pump, then turn on the air compressor, adjust the output air pressure to 0.2Mpa through the pressure regulating valve, adjust the atomization nozzle to control the atomization flow rate of 1.8L / h; the assembly line drives the meta...

example 2

[0063] Silicon-zirconium composite treatment, using silicon-zirconium composite treatment solution.

[0064] Assembly line parameters: assembly line speed 4m / s; box height 2.2m, width 1.3m;

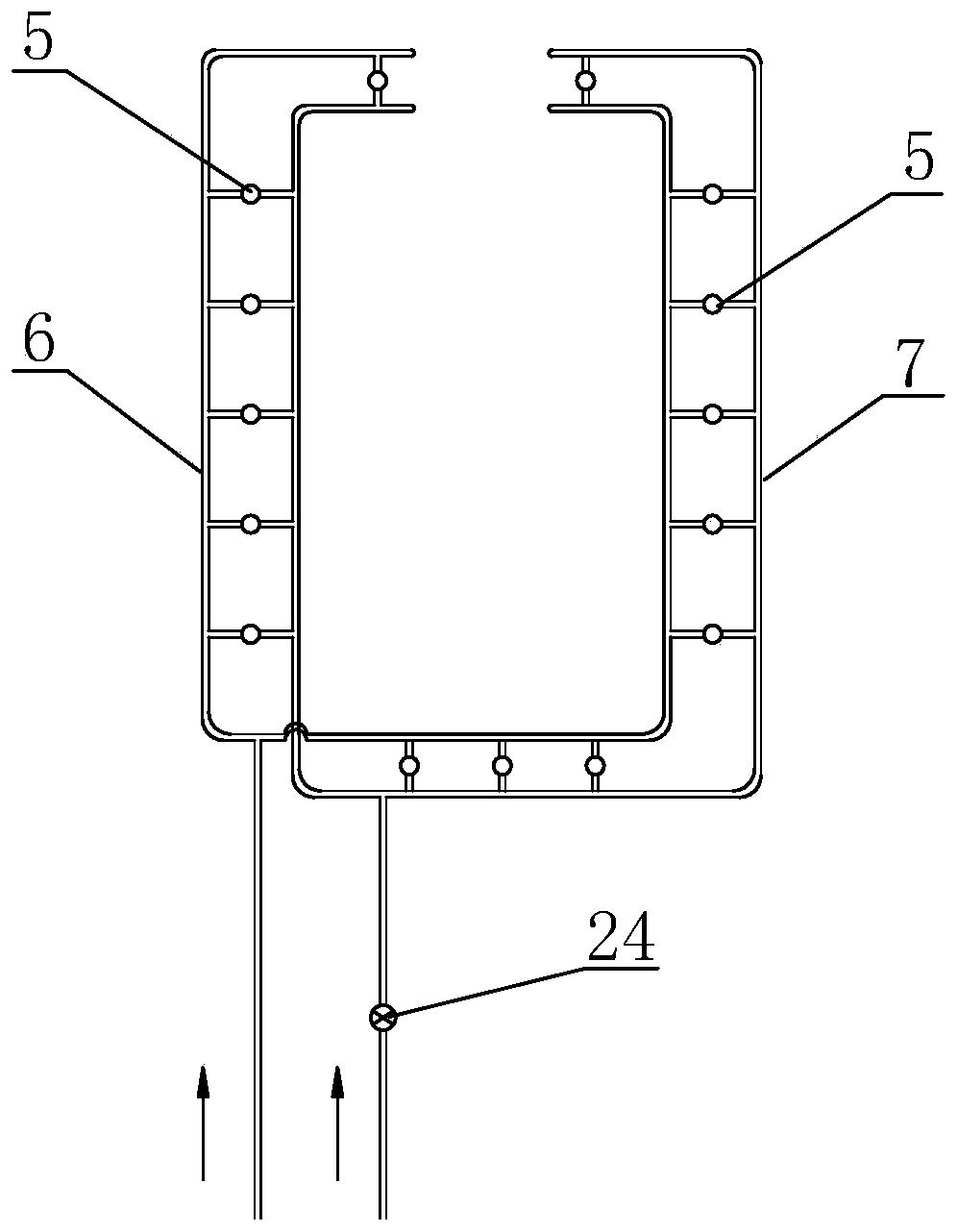

[0065] The output air pressure is 0.28Mpa, adjust the atomization nozzle to control the atomization flow rate of 3L / h;

[0066] Silicon-zirconium composite treatment liquid is used, the treatment time is 3 minutes, the length of the atomization area is kept at about 12m, 6 sets of pipelines are installed in the box, with an interval of 200cm, and 12 atomization nozzles are arranged on each set of pipelines, with 4 on each side (with an interval of 45cm) , leaving 35cm at the bottom and 50cm at the top), 2 on the bottom (50cm apart, 40cm at both ends), 2 on the top (located at the end of the top pipeline), and the nozzles on the bottom and top are facing left and right Inclined at 45°.

[0067] All the other are the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com