Antibacterial textile and preparation method thereof

A technology for antibacterial textiles and textiles, which is applied in textiles and papermaking, fiber processing, physical processing and other directions to achieve enhanced photocatalytic performance, superior photodegradation performance and bacteriostatic properties, and good photocatalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

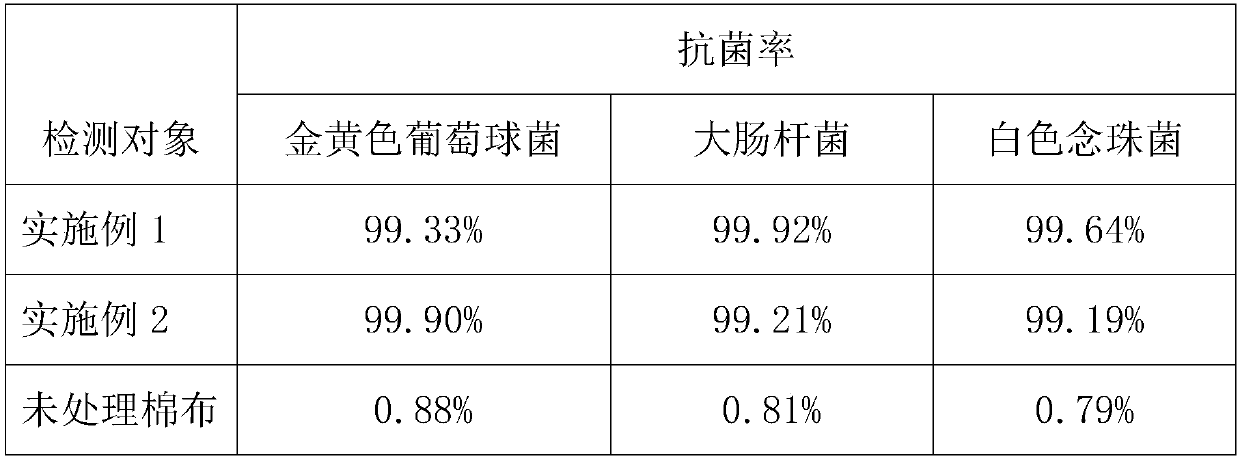

Examples

Embodiment 1

[0024] A preparation method for antibacterial textiles, comprising the following preparation methods:

[0025] 1) Corona treatment is carried out on the cotton cloth: it is carried out under the condition of a mixed gas with a volume ratio of oxygen and nitrogen of 2:8, and it is treated at 8kV for 7s;

[0026] 2) Dissolve 1 mol of silver nitrate and 2 mol of ammonium metavanadate in 30 L of deionized water, react at 150° C. for 18 h, then add 4 mol of cetyltrimethylammonium bromide, and react at 15° C. under light for 5 h. Then, add the cotton cloth after corona treatment in step 1) to the system, adopt the process of two immersion and two dehydration, and soak for 15 minutes each time; control the liquid retention rate of 120-140% for each dehydration, and dry at 60° C. for 10 hours.

[0027] 3) With the textiles treated in step 2) as the substrate, magnetron sputtering under argon conditions, gas flow rate 30sccm, pressure 1Pa, power 80W, sputtering time 20min, magnetron sp...

Embodiment 2

[0029] A preparation method for antibacterial textiles, comprising the following preparation methods:

[0030] 1) Corona treatment is carried out on the cotton cloth: it is carried out under the condition of a mixed gas with a volume ratio of oxygen and nitrogen of 2:8, and the treatment is carried out at 6kV for 9s;

[0031] 2) Dissolve 1 mol of silver nitrate and 3 mol of ammonium metavanadate in 40 L of deionized water, react at 160°C for 16 hours, then add 6 mol of cetyltrimethylammonium bromide, and react for 6 hours at 20°C under light. Then, add the cotton cloth after corona treatment in step 1) to the system, adopt the process of two immersion and two dehydration, soak for 10 minutes each time; control the liquid retention rate of 140-160% for each dehydration, and dry at 60° C. for 8 hours.

[0032] 3) With the textiles treated in step 2) as the substrate, magnetron sputtering under argon conditions, gas flow rate 40sccm, pressure 1.5Pa, power 60W, sputtering time 25m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com