Protection structure and installation process of a radiation protection wall

A radiation protection and protective structure technology, applied in building structure, covering/lining, construction, etc., can solve the problems of strong specification and size, difficult control, and general shielding effect, so as to achieve simple and convenient installation process and ensure the overall Excellent stability and radiation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

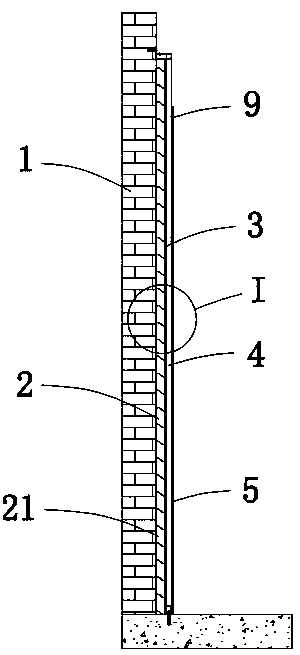

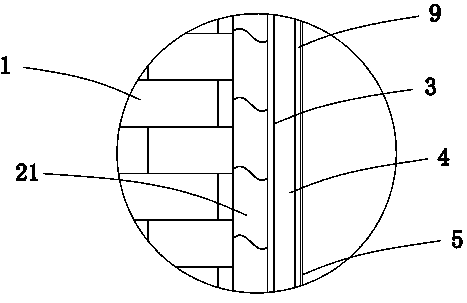

[0051] Such as Figure 1~4 As shown, a protective structure of a radiation protection wall includes a wall 1, a radiation protection layer 2 attached to the surface of the wall 1, and a fixed structure for fixing the radiation protection layer 2 to the wall 1.

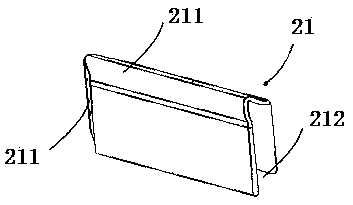

[0052] Specifically, the radiation protection layer 2 is formed by stacking radiation protection bricks 21 made of radiation protection materials. The protection form of the radiation protection layer 2 formed by stacking radiation protection bricks 21 subverts the traditional painting of the wall to ensure the protection effect. The concept can effectively avoid the protection defects caused by the cracking of the painted wall, and at the same time, the stacking of radiation protection bricks is convenient for installation and operation.

[0053] In order to make the radiation protection layer 2 stacked with radiation protection bricks achieve the effect of comprehensive protection against radiation, and also to make ...

Embodiment 2

[0072] Such as Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 lies in the difference in the fixing structure and the difference in the decorative structure caused by the difference in the fixing structure.

[0073] The fixing structure of the present embodiment includes fixing plates 3 evenly spaced on the radiation protection layer, and the fixing plate 3 is provided with a screw mandrel 6, and the screw mandrel 6 penetrates the fixing plate 3, the radiation protection layer 2 and the body of wall 1 in sequence so that The radiation protection layer 2 is fixed on the body of wall 1 .

[0074] The radiation protection layer 2 is fixed by adopting a plurality of fixing plates 3 intermittently arranged. Compared with the embodiment 1, there is no need to set the fixing keel frame 4, which simplifies the fixing structure. The stable adaptation of the groove structure 212 to the mosaic feature and the fixing plate 3 can effectively prevent the stack...

Embodiment 3

[0083] Such as Figure 7-10 As shown, the radiation protection layer 2 of the present embodiment adopts the radiation protection material to be poured and formed, and the fixed structure includes screw rods 6 evenly spaced on the radiation protection layer. Wall 1 is fixed.

[0084] The poured radiation protection layer 2 has high density and excellent protection performance.

[0085] A decorative panel 5 is attached to the surface of the radiation protection layer 2 to isolate the radiation protection layer 2 and the fixed structure from the outside.

[0086] The installation process of the above-mentioned radiation protection wall is as follows, which uses radiation protection materials to form a radiation protection layer on the wall surface by pouring method, wherein the pouring method includes the following steps:

[0087] S1. Place a formwork 8 vertically at a fixed distance from the wall 1, and the formwork 8 is provided with evenly spaced screw rods 6 to connect with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com