Heat storage combustion device with annular rotating valve

A regenerative combustion and rotary valve technology, applied in valve device, combustion method, combustion type and other directions, can solve the problems of unreasonable structural design, high leakage value, affecting the efficiency of waste gas treatment, etc., to achieve simple and stable structure and increase sealing effect. , the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

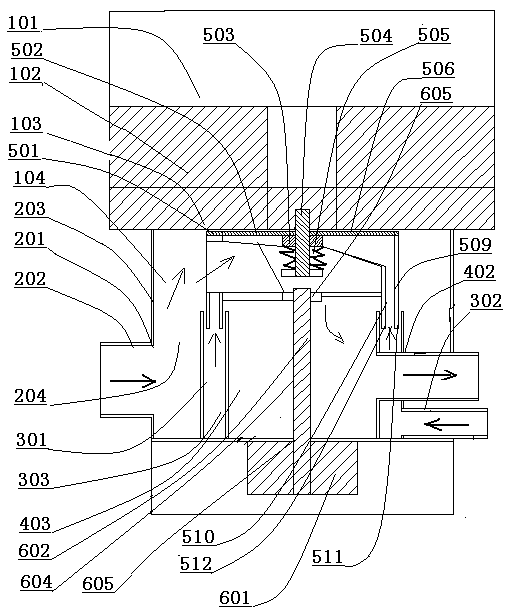

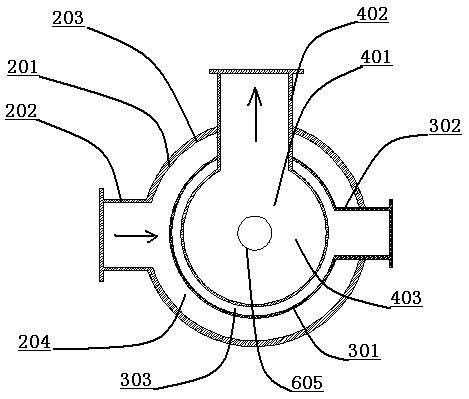

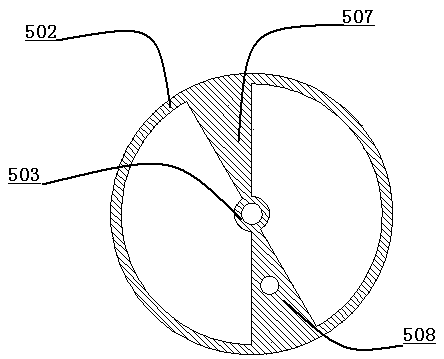

[0028] Such as figure 1 As shown, the regenerative combustion device with an annular rotary valve includes: a combustion chamber 101 , a regenerator 102 , an annular gas distribution plate 103 and an annular rotary valve 104 . The annular rotary valve 104 includes: an annular intake box 201 , an exhaust box 401 , an annular scavenging box 301 , a rotary valve core 501 and a transmission device 601 . Such as figure 2 As shown, an air intake pipe 202 is installed on the shell 203 of the annular air intake box 201 , and the air intake pipe 202 communicates with the annular air intake passage 204 inside the shell 203 . The annular scavenging air box 301 is installed inside the annular air intake box 201 , the air scavenging pipe 302 of the annular air scavenging box 301 passes through the annular air intake box 201 , and communicates with the annular air scavenging channel 303 of the annular air scavenging box 301 . The exhaust box 401 is installed inside the annular scavenging...

no. 2 example

[0031] Such as Figure 5 As shown, an annular air guide plate 801 is installed in the annular scavenging air box 301, such as Figure 6 As shown, the retaining ring 802 of the annular air guiding plate 801 is provided with several air guiding holes 803, and the air guiding holes 803 are connected with an air guiding tube 804 installed thereon. Such as Figure 5 As shown, the retaining ring 802 of the annular air guide plate 801 is installed in the middle of the annular scavenging air box 301 , and the purge cleaning gas in the annular air scavenging box 301 is discharged through the air guide hole 803 and the air guide pipe 804 . Such as Figure 5As shown, one or more annular porous seals 805 are installed on the annular air guide plate 801 . like Figure 7 As shown, the through hole 806 of the annular porous seal 805 is sleeved on the outside of the air duct 804 , and the annular porous seal 805 contacts and seals the inner walls of the outer ring 511 and the inner ring 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com