Microfossil nondestructive separation method

A separation method and fossil technology, which is applied in the field of analysis of micro-paleontological fossils, can solve the problems of poor harvest rate and integrity of micro-fossils, serious acid corrosion of micro-fossils, etc., and achieve low cost of test equipment and materials, and low operating procedures simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

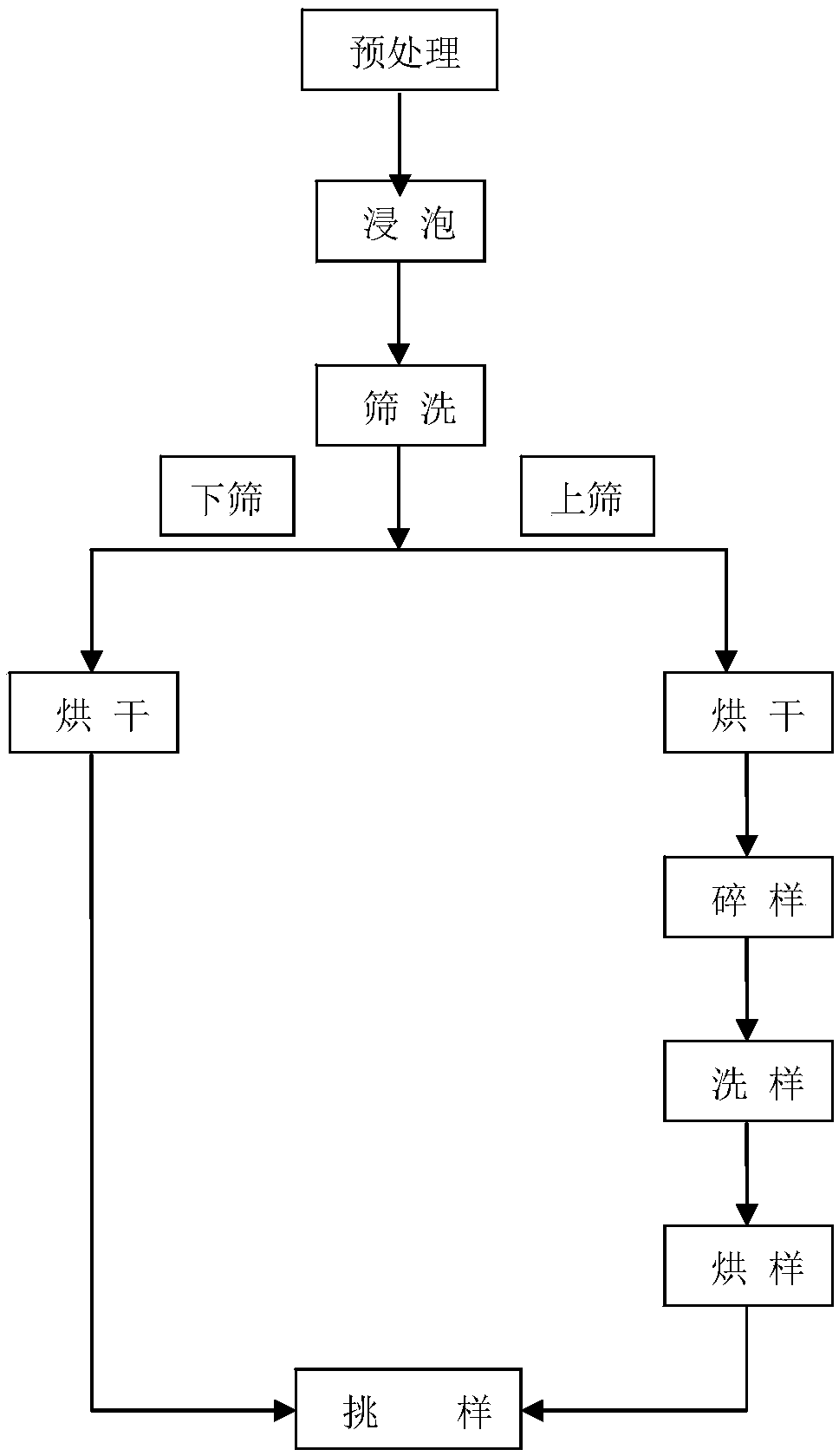

[0027] The non-destructive separation method of microfossils in this embodiment, the flow chart is as follows figure 1 As shown, the following steps are taken:

[0028] 1) Use a crushing machine or hand hammer to crush the rock sample into 3cm 3 The small pieces are uniformly numbered and placed in the sample cylinder;

[0029] 2) At room temperature, add glacial acetic acid solution with a mass concentration of 15% to the sample tank, the glacial acetic acid solution completely covers the sample, and the sample is completely loose after soaking for 24 hours;

[0030] 3) The soaked sample is washed with a set of sieves consisting of an upper sieve and a lower sieve (while rinsing and sieving). Dry the samples to obtain the upper sieve sample block and the lower sieve sample respectively;

[0031] 4) The upper sieve sample block is crushed with a rock crusher or hand hammer until the particle size is not greater than 2mm, and then the upper sieve sample is obtained through s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com